DK00026.fm

REPAIR MANUAL

BRP-Powertrain

Effectivity: 125 MAX/125 Junior MAX/125 Mini

MAX/125 Micro MAX

Edition 2 / Rev. 0

Chapter 4

Page 14

December 01/2010

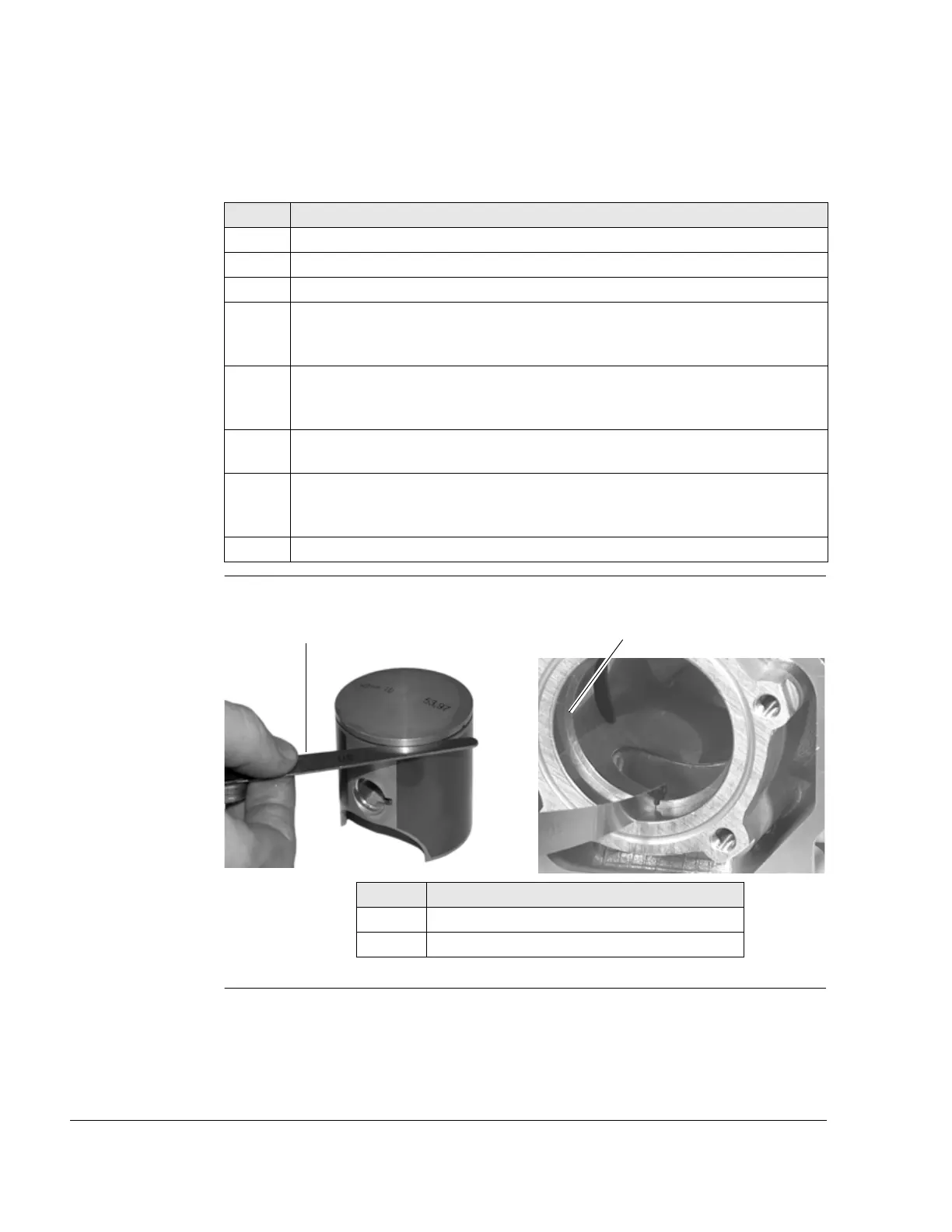

3.2) Inspection of piston and piston ring

Instructions See Figure 7.

Graphic Piston and piston ring

Figure 7

K00137,K00052

Step Procedure

1 Inspect the piston for cracks and signs of piston seizure.

2 Inspect the bore of the piston pin for damage and wear.

3 Inspect the piston pin circlip groove for defects.

4 Check free of movement of the piston ring in the ring groove.

NOTES: If carbon prevents free movement of the piston ring, the

ring groove can be cleaned out with a discarded piston ring.

5 Measure the piston ring clearance in the ring groove with a feeler gauge (1).

NOTES: If the piston ring clearance has reached the wear limit of

0.1 mm, the piston must be replaced.

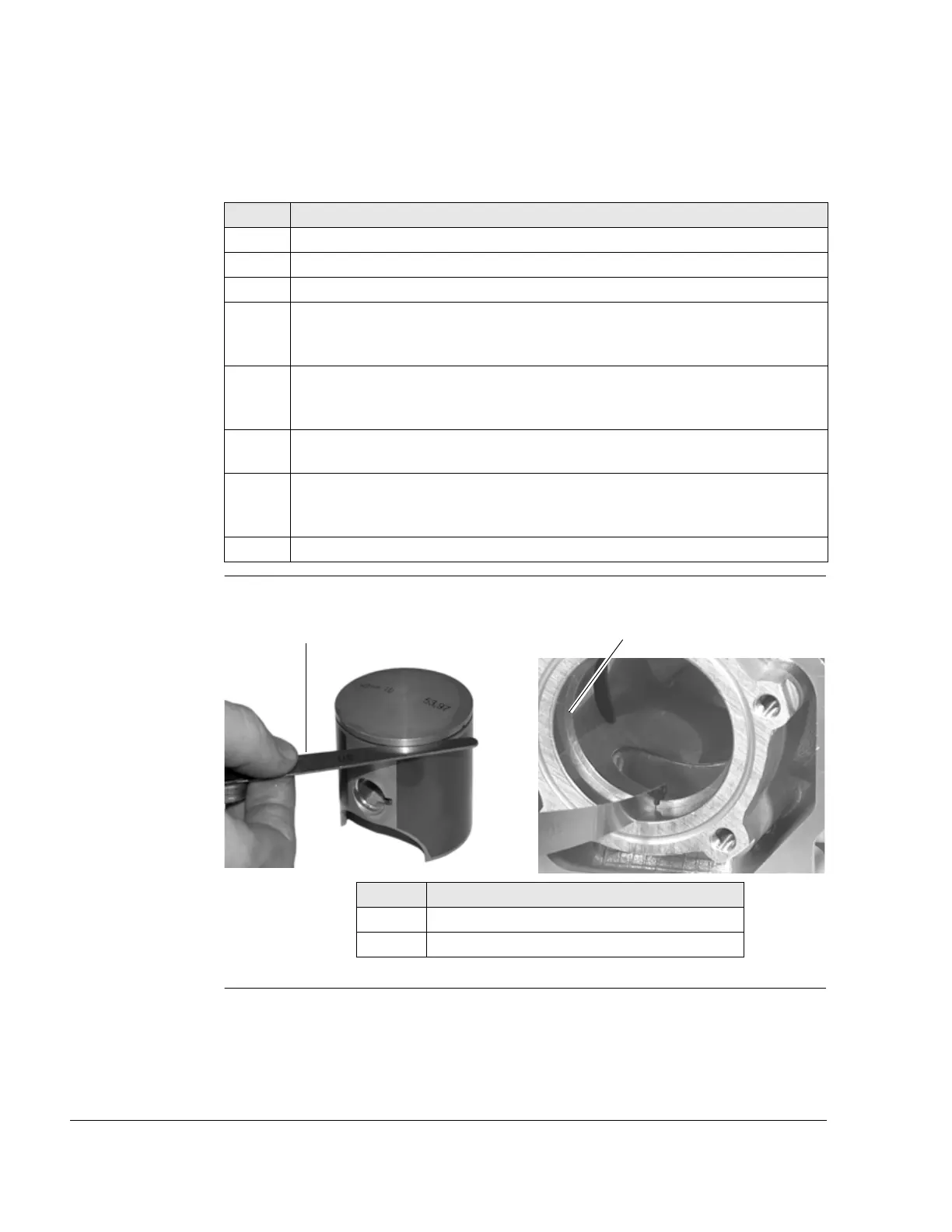

6 Remove the piston ring and insert a feeler gauge into the cylinder parallel to

the head sealing surface (approx. 10 mm from the top of the cylinder).

7 Measure clearance with a feeler gauge.

NOTES: If the wear limit of 0.8 mm has been reached the piston ring

must be replaced.

8 Check the piston ring locking pin for wear.

Part Function

1 Feeler gauge

2Piston ring

Loading...

Loading...