DK00026.fm

REPAIR MANUAL

BRP-Powertrain

Effectivity: 125 MAX/125 Junior MAX/125 Mini

MAX/125 Micro MAX

Edition 2 / Rev. 0

Chapter 4

Page 13

December 01/2010

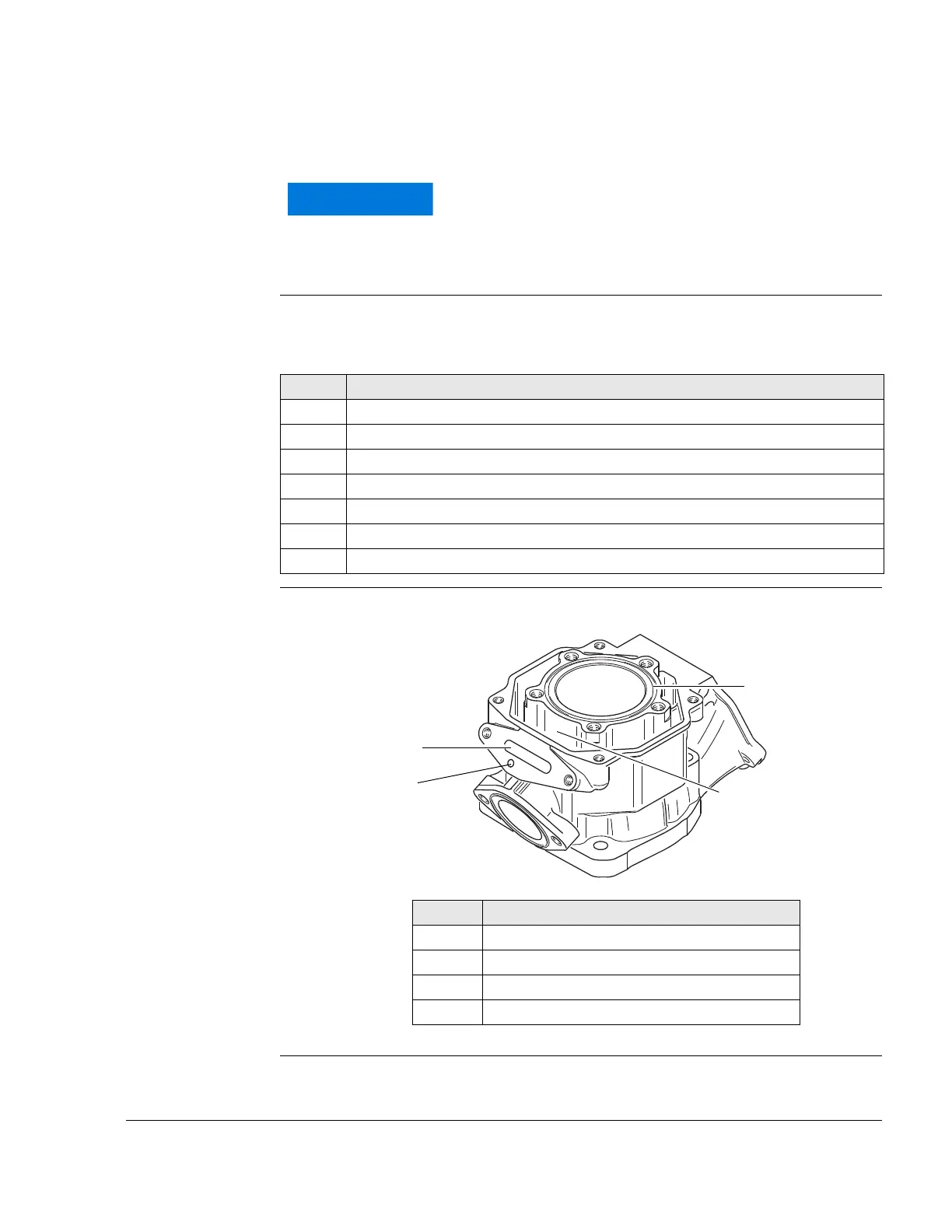

3) Inspection of cylinder parts

General

3.1) Inspection of cylinder

Instructions See Figure 6.

Graphic Cylinder

Figure 6 K00027

Components, which have reached or exceeded their

wear limits, must be replaced. Components, which

are found to be defective in the context of the visual

inspection and might influence the engine's perform-

ance, must also be replaced.

Step Procedure

1 Remove lime deposits (1) from the water cooling of the cylinder.

2 Clean combustion residues from the exhaust valve and slider duct (2).

3 Clean O-ring groove (3).

4 Inspect all threads.

5 All sealing surfaces must be clean and smooth.

6 Inspect the cylinder bore for abnormal wear.

7 Inspect the impulse bore.

Part Function

1 Possible lime deposits

2 Slider duct

3 Groove for O-ring

4 Impulse bore

Loading...

Loading...