DK00027.fm

REPAIR MANUAL

BRP-Powertrain

Effectivity: 125 MAX/125 Junior MAX/125 Mini

MAX/125 Micro MAX

Edition 2 / Rev. 0

Chapter 5

Page 27

December 01/2010

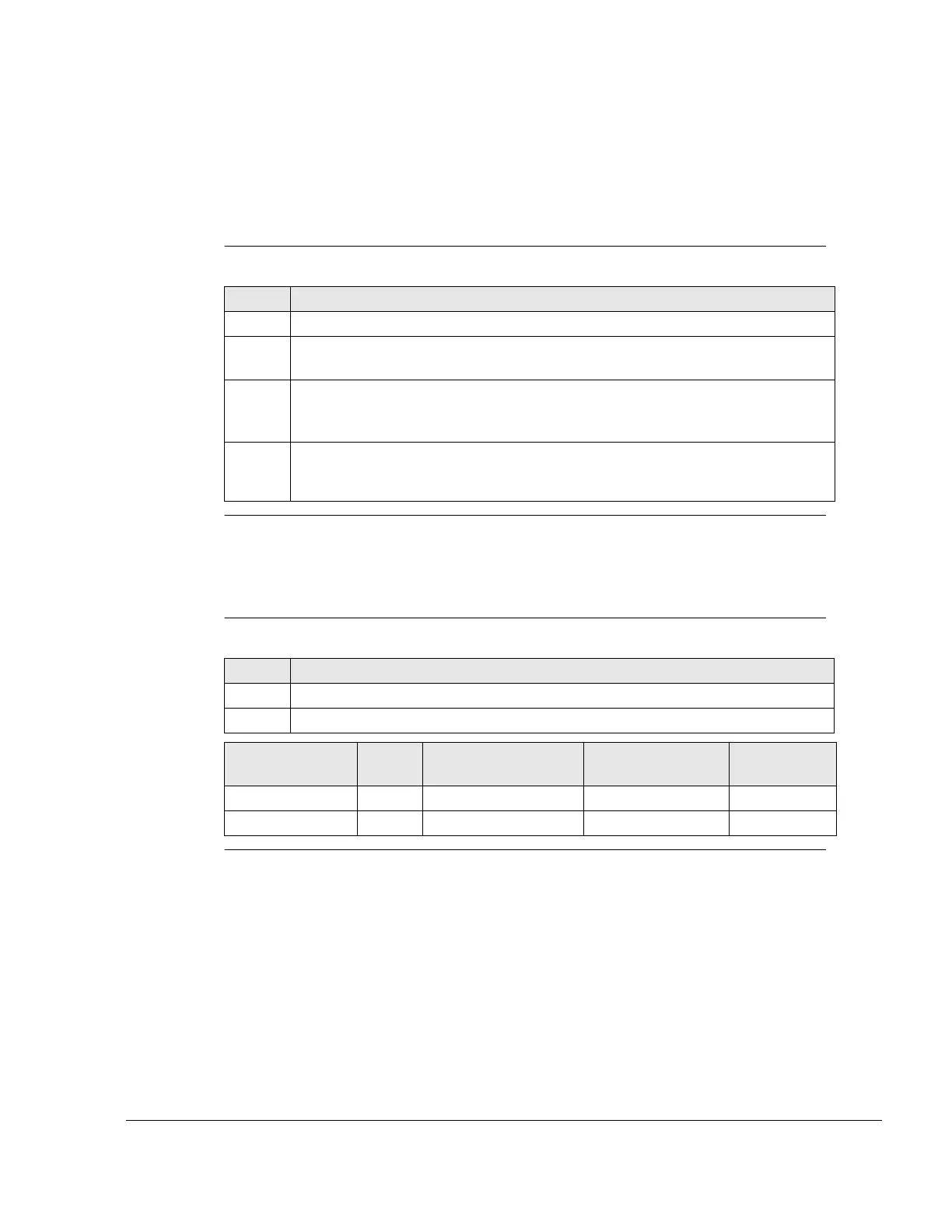

4.2) Inspection of balance shaft drive

General NOTES: If one of the balance wheels has cracks or if backlash of

the balance wheels at the spline can be seen, both bal-

ance wheels must be replaced.

Instructions See Figure 17.

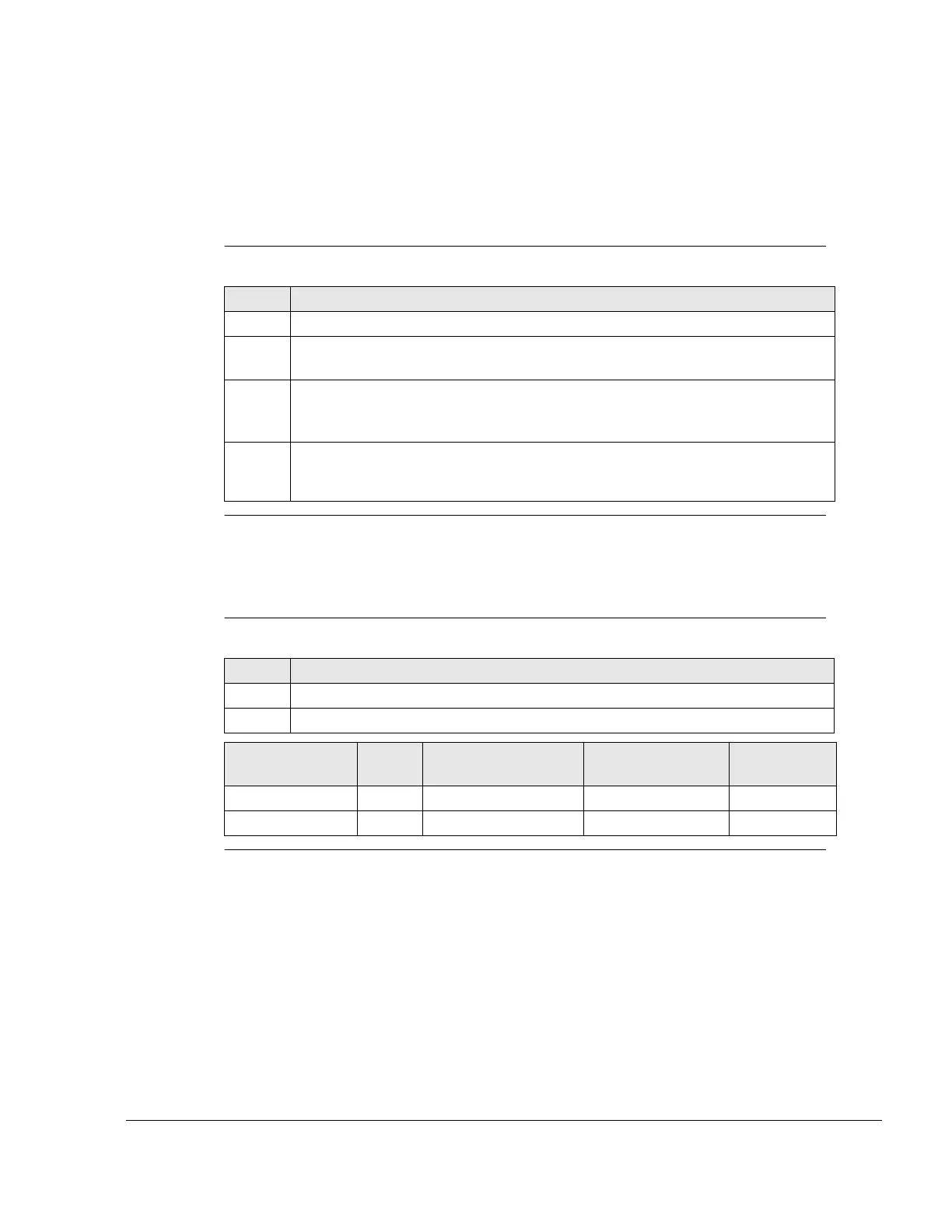

4.2.1) Inspection of balance shaft

General NOTES: If one of the wear limits M10 or M11 is reached, the

balance shaft must be replaced.

Instructions See Figure 17.

Step Procedure

1 Check balance gears (1) for cracks.

2 Place balance gears on the spline, the balance shaft or crankshaft and inspect

balance gears for backlash at the spline.

3 Check outer teeth of the two balance gears for signs of wear. If the teeth of one

of the balance gears shows signs of wear, both balance gears must be re-

placed.

4 Inspect condition of O-ring (2).

NOTES: The balance gears (1) and the O-ring (2) should be replaced

at least every 50 operating hours.

Step Procedure

1 Inspect the groove (3) for the locking ring for damage and wear.

2 Check the diameter of the bearing seats M10 and M11 for wear.

Description Code New dimension Wear limit

Measured

value

Bearing seat M10 14.96 mm - 14.99 mm 14.94 mm

Bearing seat M11 24.97 mm - 24.99 mm 24.94 mm

Loading...

Loading...