Section 04 ENGINE (2-STROKE)

Subsection 04 (TOP END)

947 DI Engines

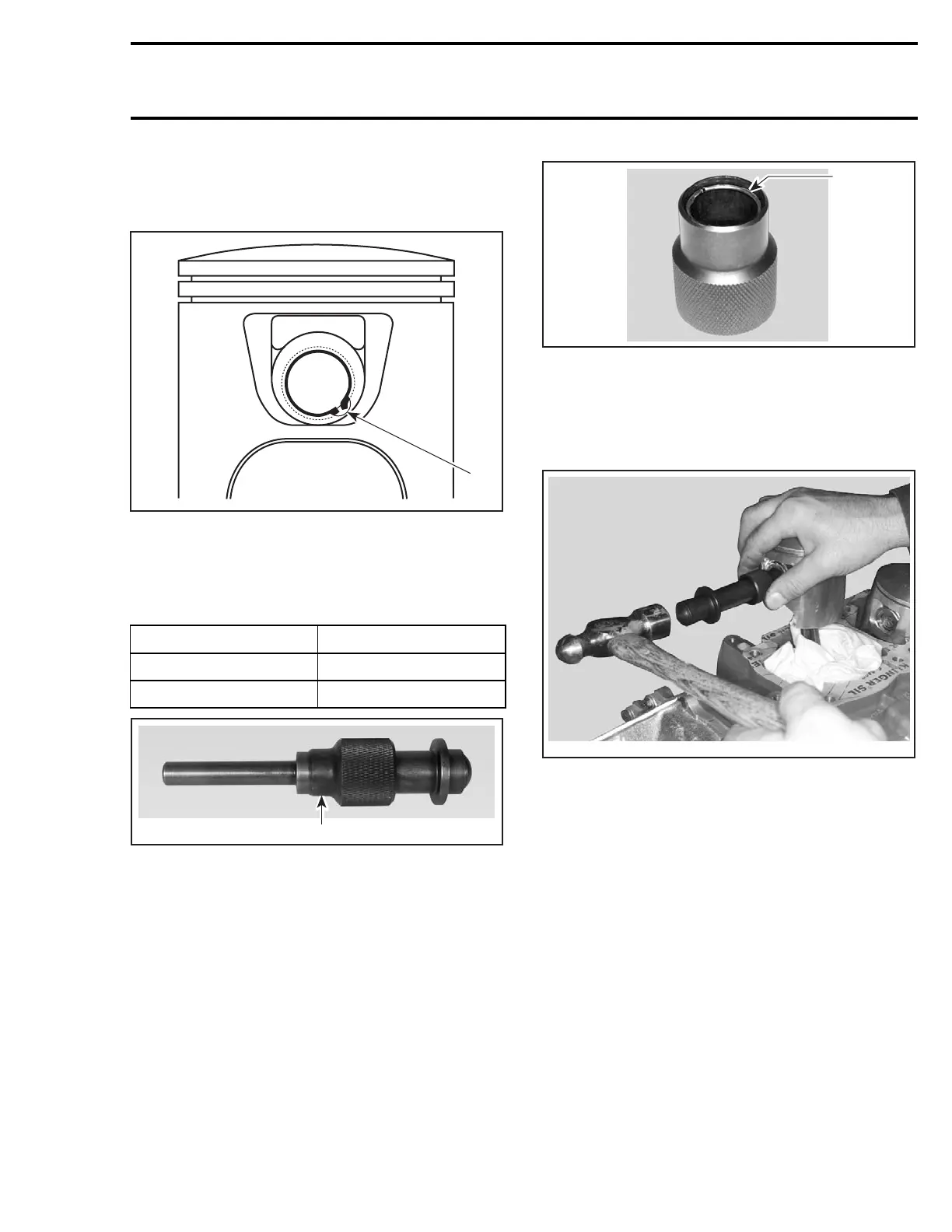

Securecirclipinpistongroovewithitsbentendin

piston notch as shown.

1

F07D0AB

1. Circlip end in piston notch

All Engines

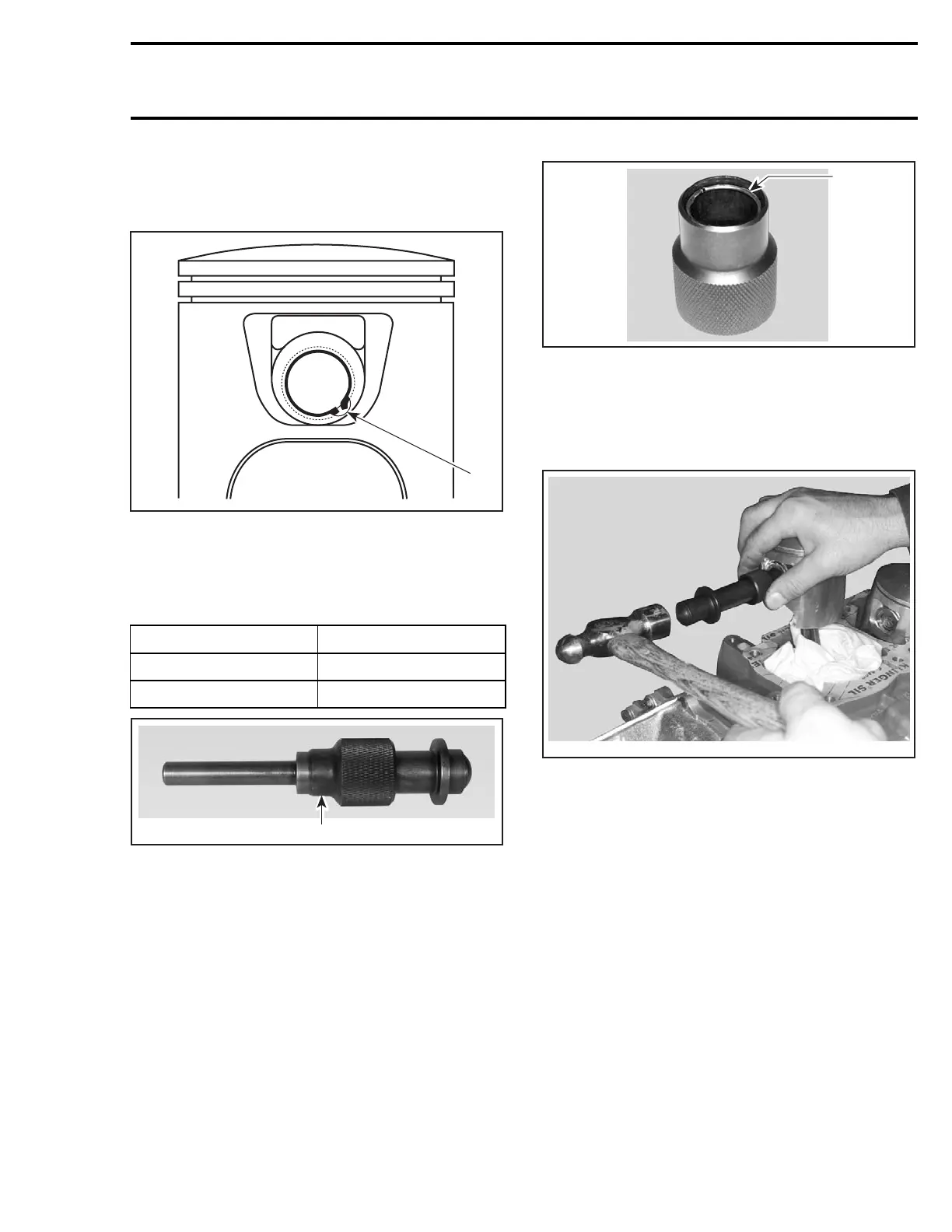

To easily insert circlip into piston, use circlip in-

staller.

ENGINE TOOL P/N

717 and 787 RFI 529 035 562

947 DI 529 035 563

F06B01A

1

TYPICAL

1. Circlip installer

– Remove sleeve from pusher then insert circlip

into its bore.

– Reinstall sleeve onto pusher and push until cir-

clip comes in end of tool.

F00B0QA

1

TYPICAL

1. Circlip near end of tool

– Position end of tool against piston pin opening.

– Firmly hold piston against tool and tap tool with

a hammer to insert circlip into its groove.

F00B0RA

CAUTION: The hand retaining the piston

should absorb the energy to protect the con-

necting rod.

Cylinder Base Gasket

Install new base gasket.

NOTE: The general procedure is to install a new

gasket of the same thickness. However, if you

do not know the gasket thickness that was in-

stalled or if a crankshaft and/or crankcase repair

or replacement was involved, refer to the COM-

BUSTION CHAMBER VOLUME MEASUREMENT

to properly determine the required gasket thick-

ness.

Five thicknesses of cylinder base gaskets are avail-

able for a precise adjustment of the squish gap.

To identify gasket thickness, refer to the identifi-

cation holes on the gasket.

smr2004-Complete Line Up 121

Loading...

Loading...