SECTION 26: INSTRUMENT BREAKDOWN InSpec Sampler Controller

SECTION 26: INSTRUMENT BREAKDOWN

No.1 Pozidriv (cross-head) Screwdriver

2.5mm Hexagon Wrench or Allen Key

4mm Hexagon Wrench or Allen Key

7mm Combination Spanner

Modern electronic devices are very sensitive to static electric charges.

Use a grounding wrist strap at all times - See section 0 for more details

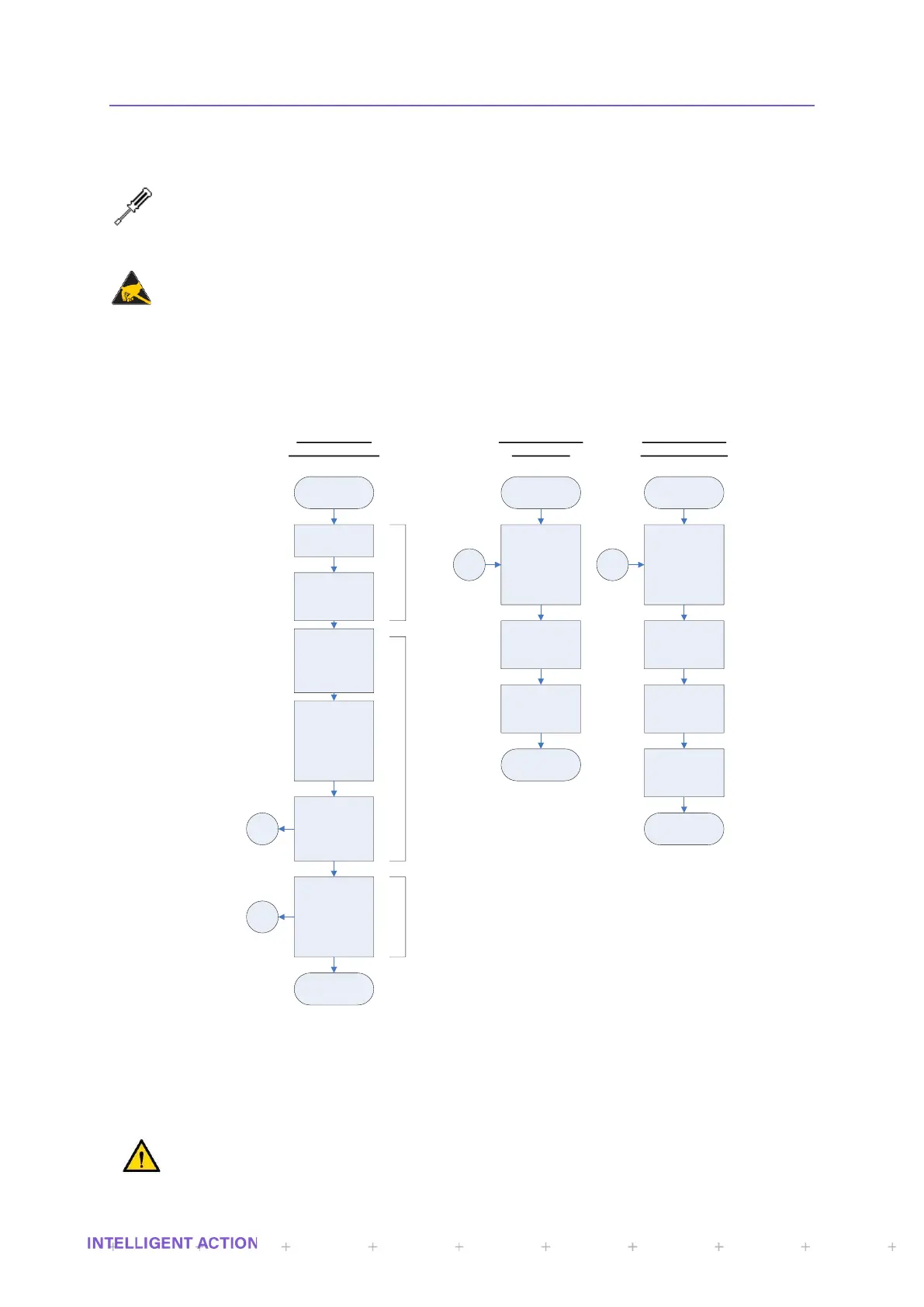

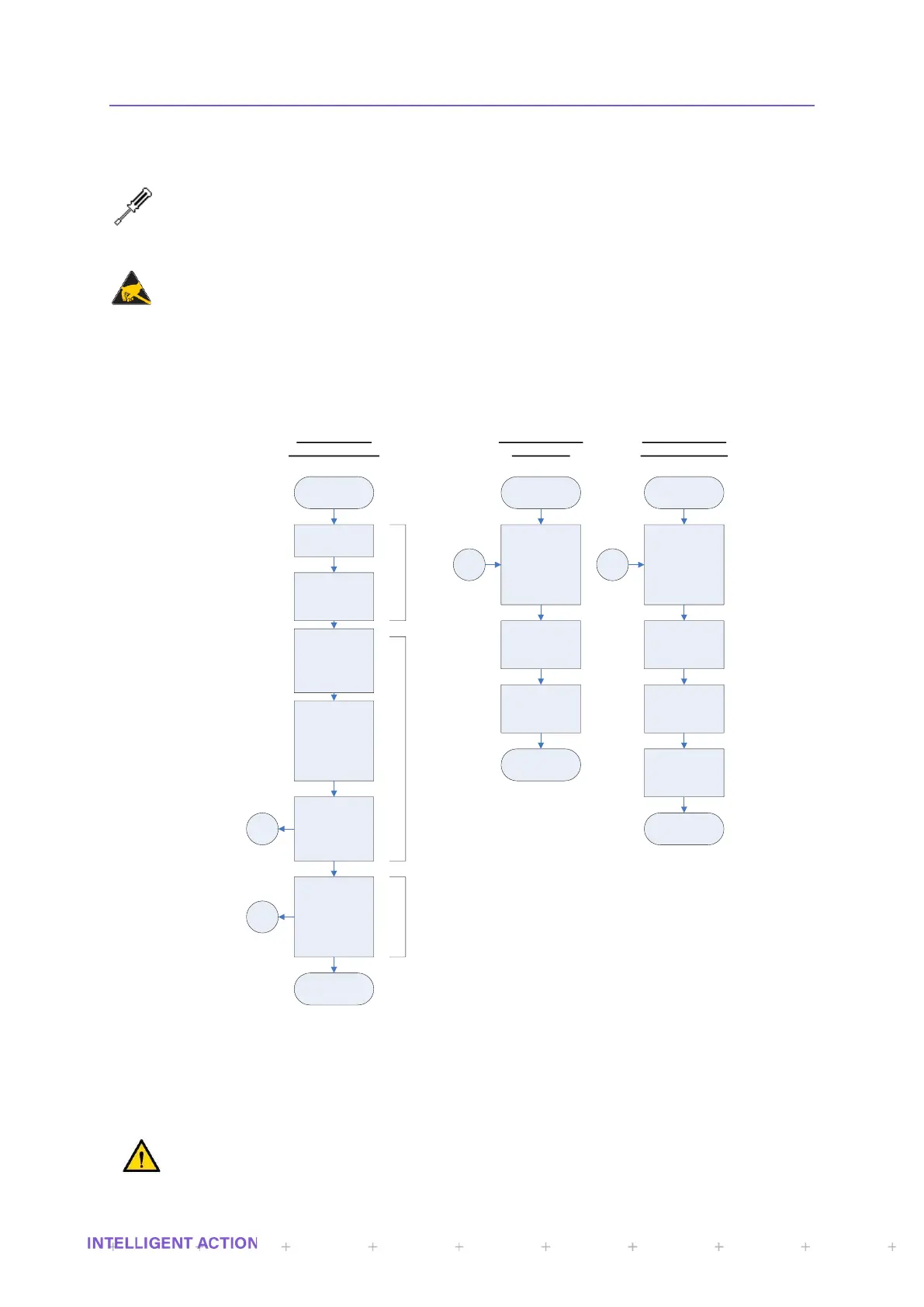

26.1 DISASSEMBLY

The following flowchart provides an overview of dismantling the unit into its component parts, which

maybe required for configuration, service or repair. Only suitably instructed or skilled persons should carry

out this work: -

START

Power down

instrument

Remove

connectors from

rear of instrument

Using 2.5mm

Allen Key, undo

fixing screw from

bottom of front

panel.

Hinge front panel

forward, then lift

panel up to

remove from main

body of the

instrument

Remove external

cables

Removing the front

panel

Disconnect ribbon

cable from front

panel, before

removing front

panel completely

Using a 4mm

Allen Key, undo

the adjustable

latches and

remove the case

from the panel

Removing the main

case

END

START

Remove the 6

fixing screws

holding the

moulding and

metalwork

together

Remove the 4

fixing screws

holding the PCB

into the moulding

The PCB and

keypad can now

be removed

END

START

Remove the six

fixing screws

holding the sheet

metalwork onto

the front of the

extrusion

1

1

2

2

Remove all nuts

and washers from

the CEP on the

instrument rear

F3174 & F3175

may be removed

at this point.

F3172 may be

removed at this

point

END

Removal from

instrument panel

Dismantling the

front panel

Dismantling the

main instrument

Figure 59 - InSpec Disassembly Flowchart

26.2 REASSEMBLY

Reassembly is the reverse of disassembly.

Protective Earth (PE)

Pay particular attention to the reassembly of the CEP when rebuilding the instrument.

Loading...

Loading...