- 155 -

14. Making Program Pattern Table and Data Table

Before setting program, make a program pattern table and data table.

14.1 Making Program Pattern Table

Please make a copy of the program pattern table (p.157), and follow the procedure below.

(1) Write a step SV, step time, PID block number, Wait function Enabled/Disabled for

each step from Step 1 in numerical order.

(Even if the same block number is used, write for every step.)

(2) Draw a line graph of step SV.

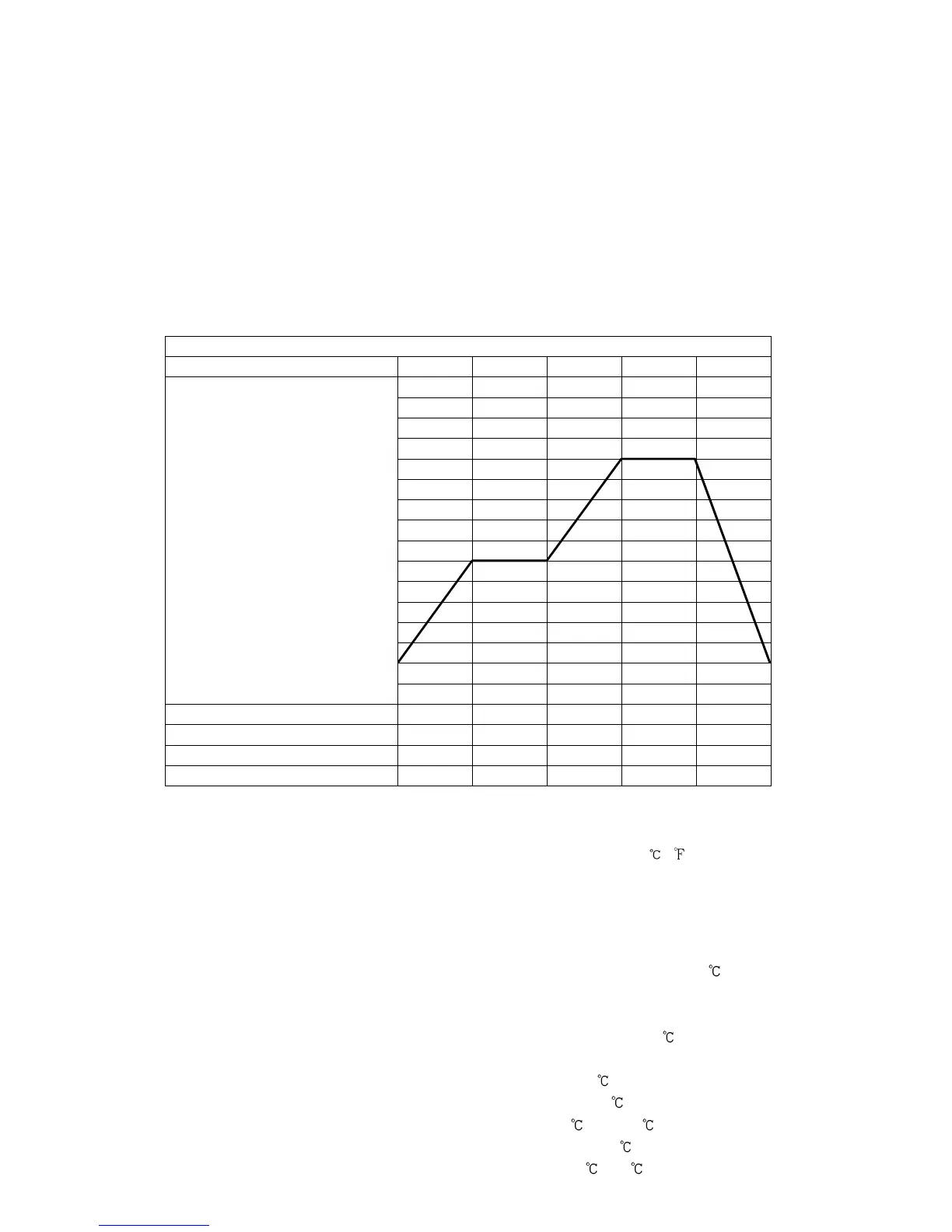

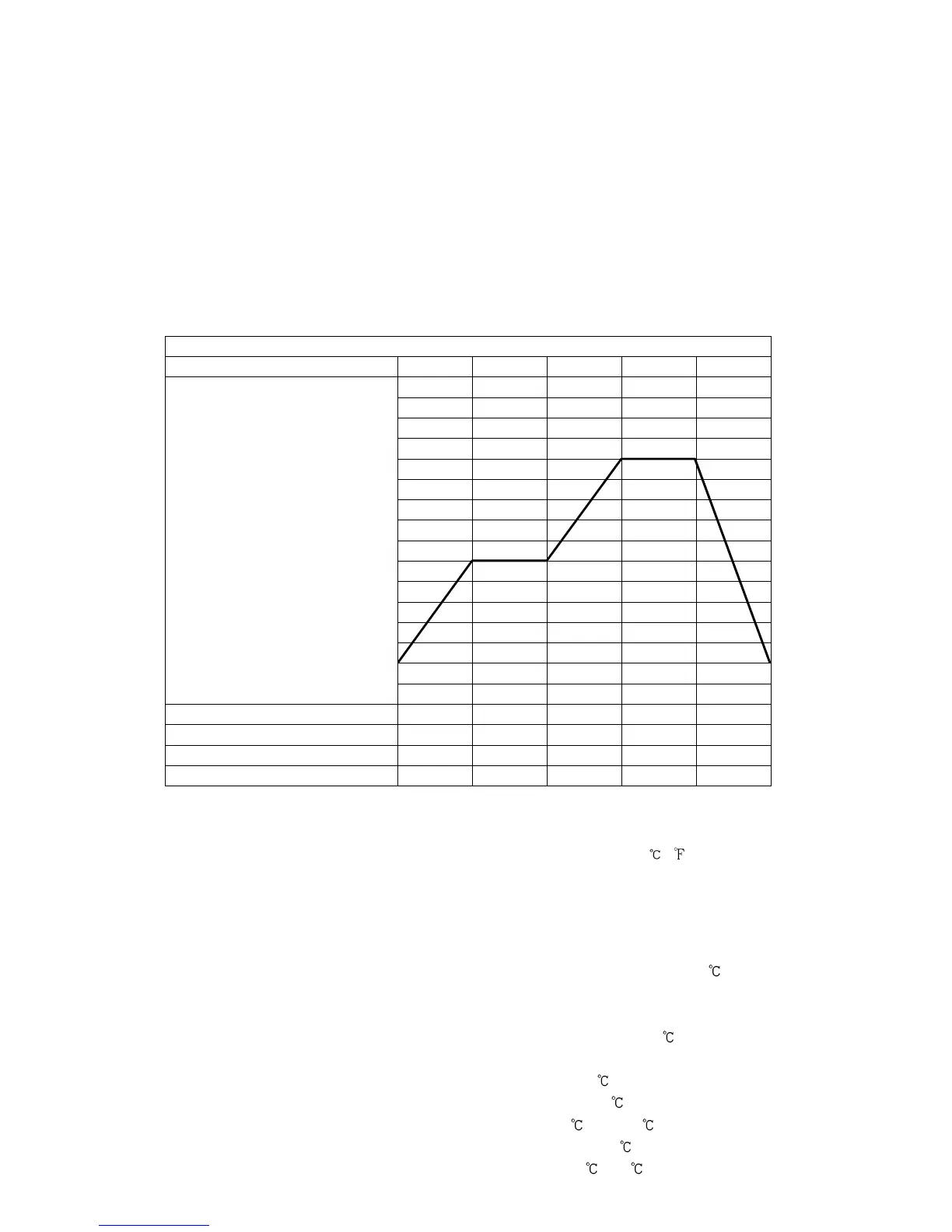

Program Pattern Table

(Fig. 14.1-1)

Explanation of Program Pattern Table

Program pattern table consists of Y axis which represents the step SV ( , ), and X axis which

represents the step time (Hours : Minutes, Minutes : Seconds).

Step SV is considered to be the SV at the end of the step.

Step time is considered to be the step process time.

• The relation between the step SV and step time can be explained as follows.

Step 1: The control is performed so that the temperature reaches from 0 to 500 for 30 minutes.

Depending on the selection in [Program control start type], control is performed as follows.

• When SV start is selected: Performs control from the step SV set in [Step SV when

program control starts] so that the temperature reaches 500 .

• When PV start or PVR start is selected: Step SV and time are advanced to PV, and

control starts so that the temperature reaches 500 .

Step 2: The control is performed so that SV is maintained at 500 for 1 hour.

Step 3: The control is performed so that SV rises from 500 to 1000 for 40 minutes.

Step 4: The control is performed so that SV is maintained at 1000 for 1 hour.

Step 5: The control is performed so that SV drops from 1000 to 0 for 2 hours.

0

500

1000

Loading...

Loading...