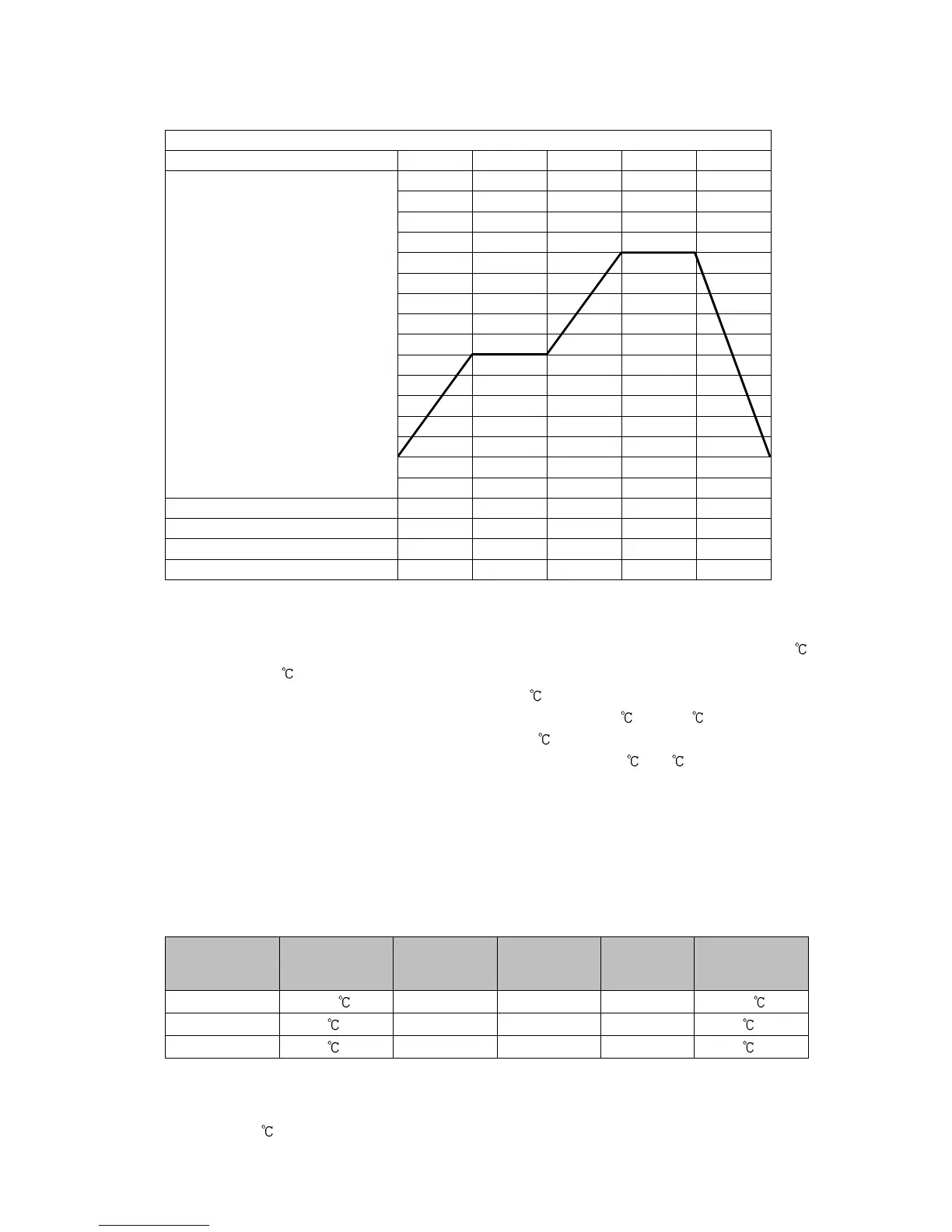

(Fig. 7.2-1)

Explanation of Program Pattern

Step 1: After program control starts, control is performed so that SV gradually rises from 0

to 500 for 30 minutes.

Step 2: Control is performed to keep the SV at 500 for 1 hour.

Step 3: Control is performed so that SV gradually rises from 500 to 1000 for 40 minutes.

Step 4: Control is performed to keep the SV at 1000 for 1 hour.

Step 5: Control is performed so that SV gradually falls from 1000 to 0 for 2 hours.

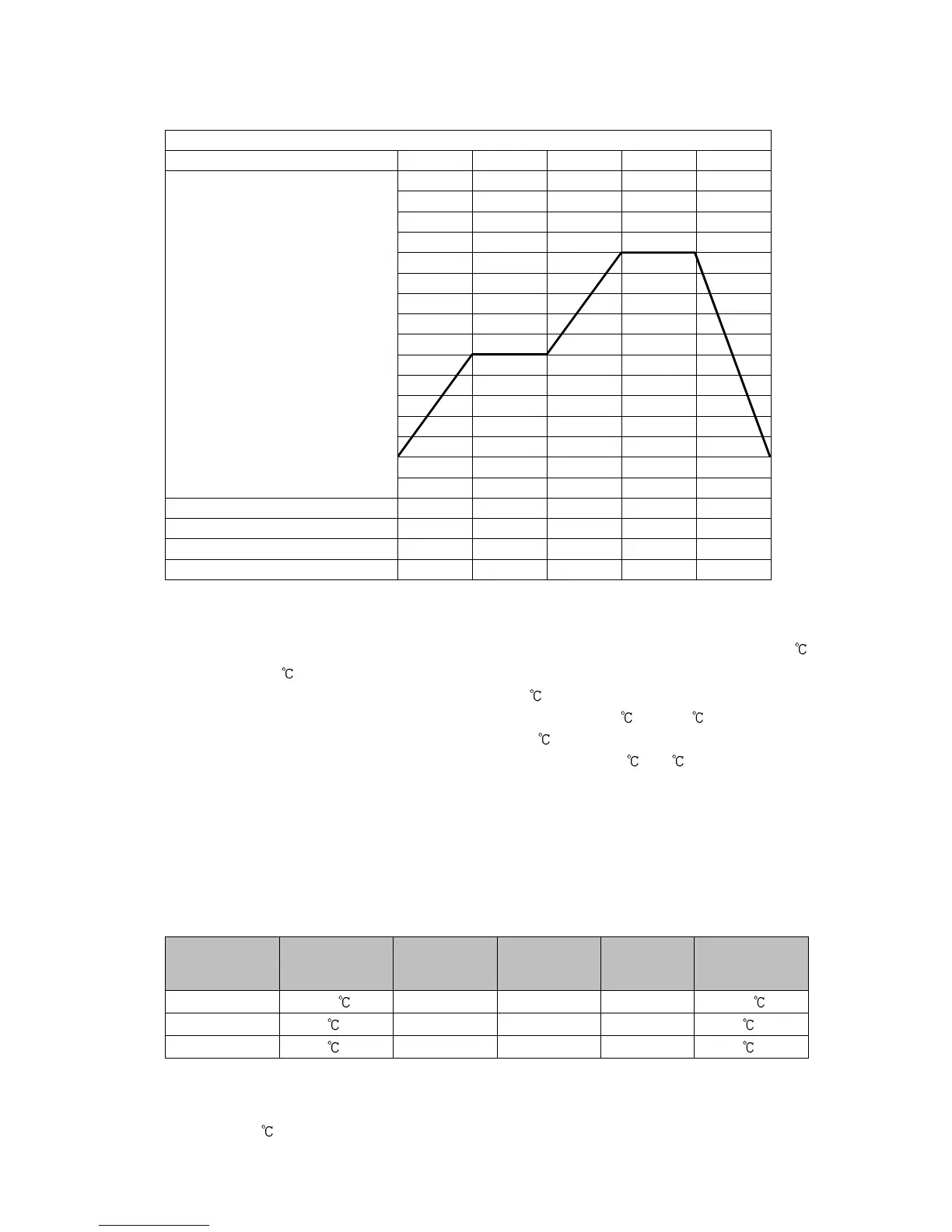

• Example of PID Block Setting

If program pattern is not set for a step, its PID block number becomes 1 (factory default).

We highly recommend that you leave the factory defaults of PID block 1 as they are, and

set the values from Block 2.

Control parameters such as PID, ARW are common to all patterns.

Block

number

proportional

band

1 10 200 sec 50 sec 50% 10

2 10 (*) 200 sec (*) 50 sec (*) 50% (*) 10 (*)

3 10 (*) 200 sec (*) 50 sec (*) 50% (*) 10 (*)

(*) Setting items in PID block are determined after performing AT. So they are currently factory default values.

• Example of Wait Value Setting

Wait value: 10

Wait value is common to all steps of each pattern.

0

500

1000

Loading...

Loading...