CAUTION

The programs are automatically controlled.

The device no longer measures correctly when a program is interrupted with Start/

Pause/Stop/Continue.

b

Only use these functions when you are sure you can assess the consequences.

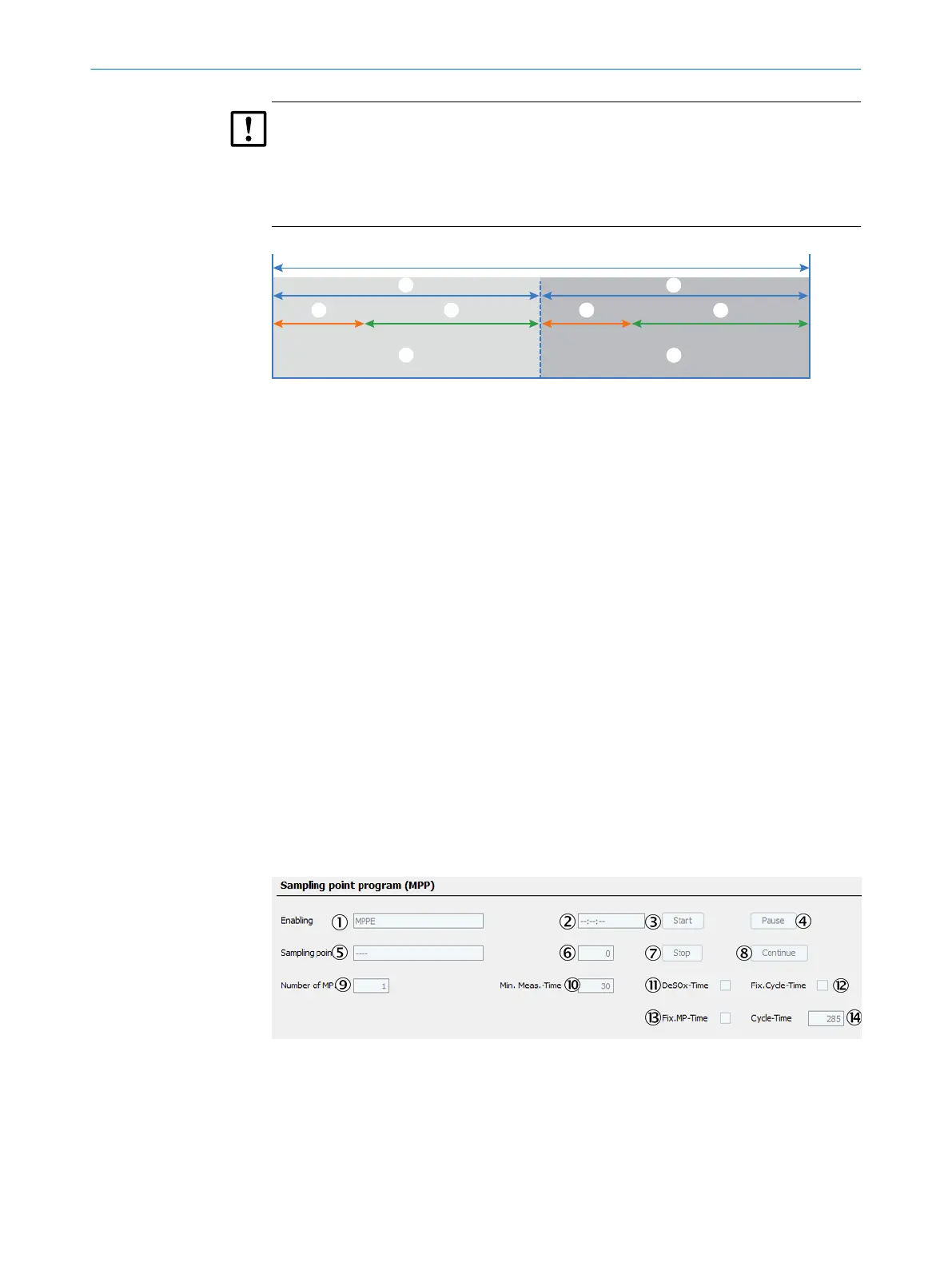

Figure 73: Measuring point switchover - diagram

1

Measuring point 1

2

Measuring point 2

3

Hold time

4

Active

5

Duration

6

Cycle time

Cycle time

The complete defined measuring cycle including measuring point switchover is com‐

pleted within the cycle time.

Duration

The time during which a measuring point is active and measuring (including run-in time

after measuring point switchover).

Hold time

After measuring point switchover: The time in which the last valid measured value of

the measuring point is held until the new measuring point has run-in (purge processes

etc.).

The hold time can be entered individually for each measuring point and serves, for

example, to control the release of the measured value to Modbus or similar.

Active

Valid measured values of the active measuring point are available after the run-in time.

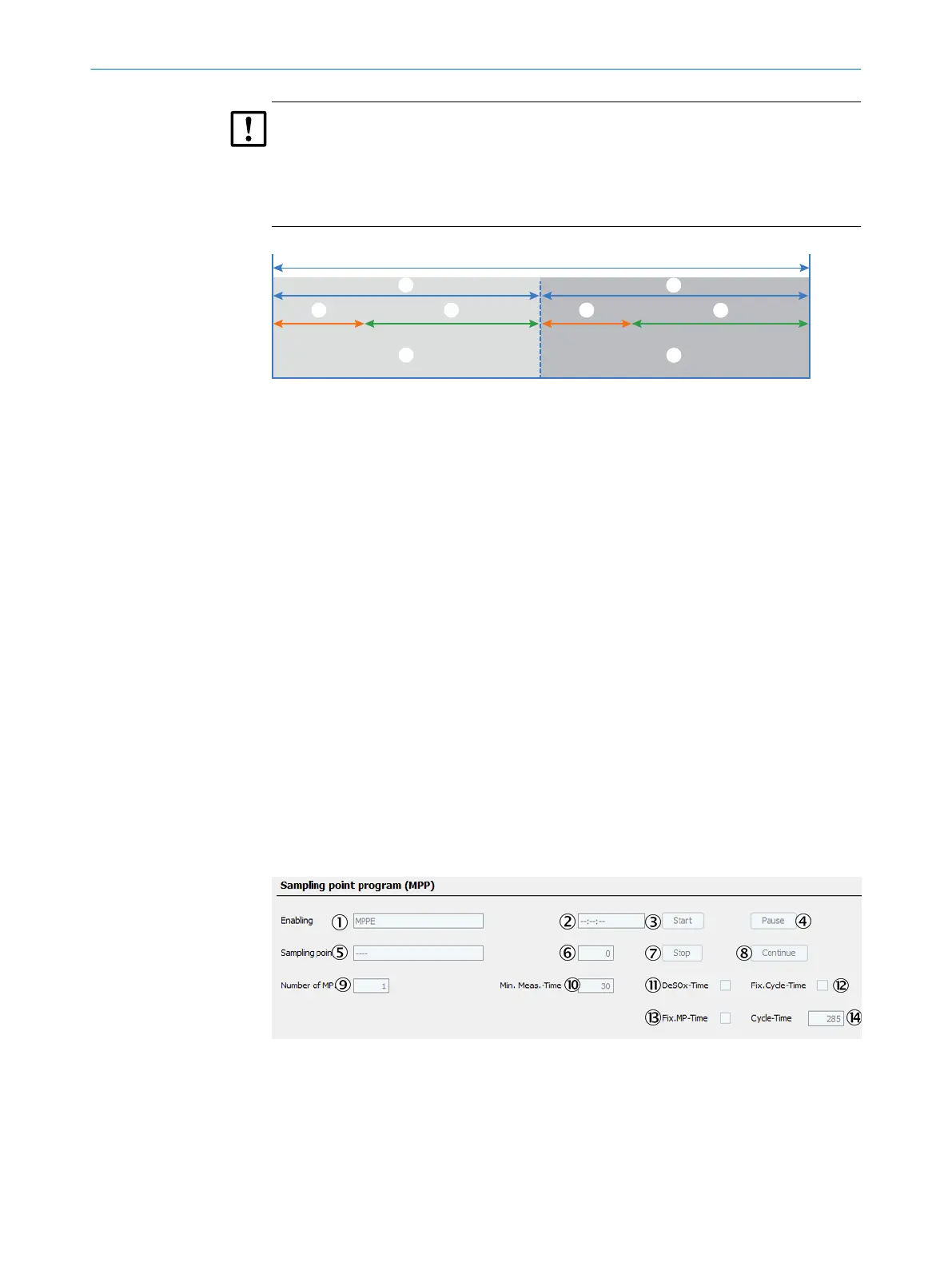

Figure 74: Menu Sampling point program (MPP)

1

Display: Internal tag to enable the sampling point program

2

Display: Run-time for the current sampling point

3

Start the sampling point program

4

Interrupt the sampling point program (pause)

5

Display: Active sampling point

6

Display: Index of active sampling point

PARAMETERIZATION 6

8017585/YXD9/V3-1/2017-05 | SICK T E C H N I C A L I N F O R M A T I O N | MARSIC300

53

Subject to change without notice

Loading...

Loading...