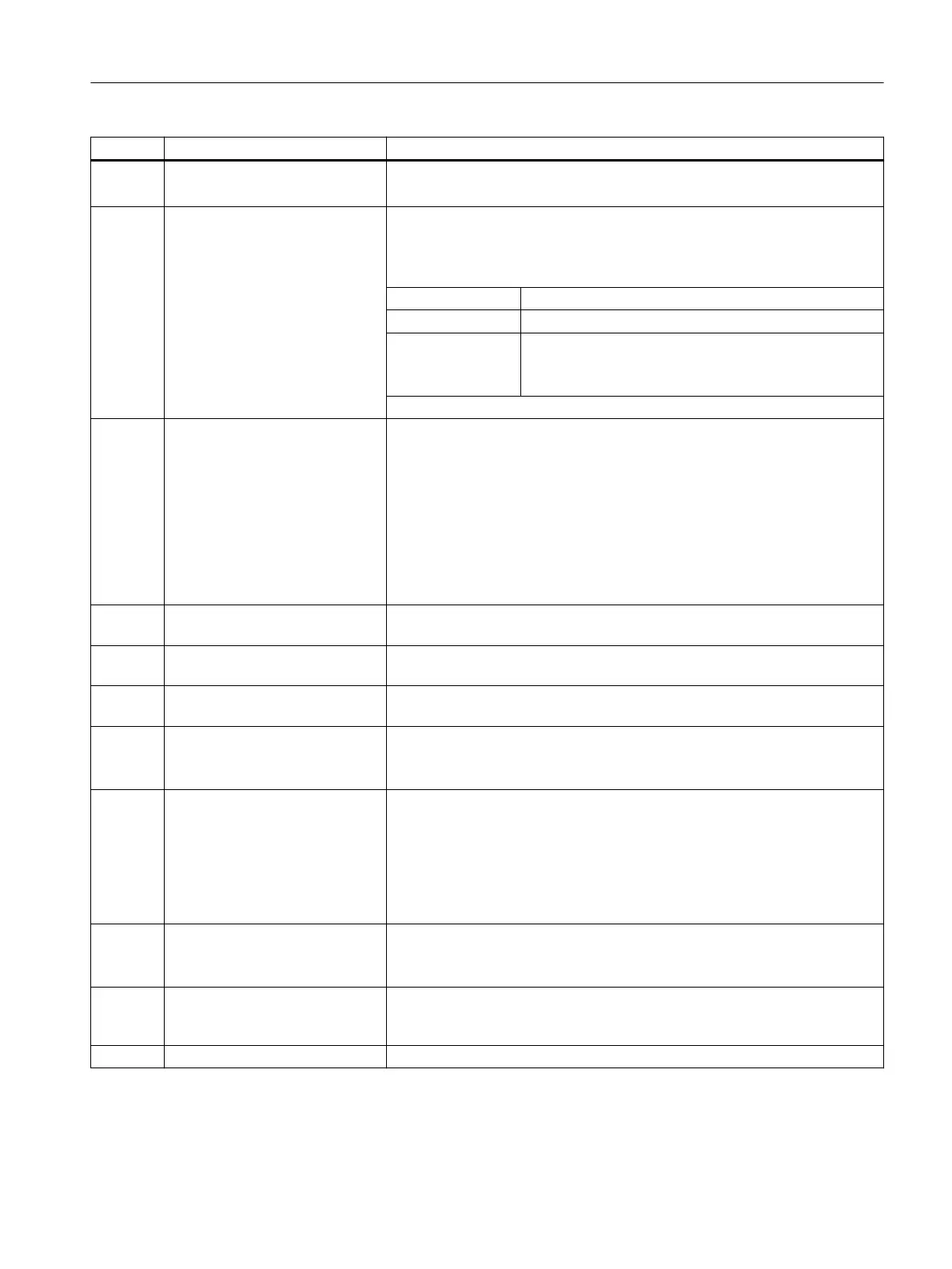

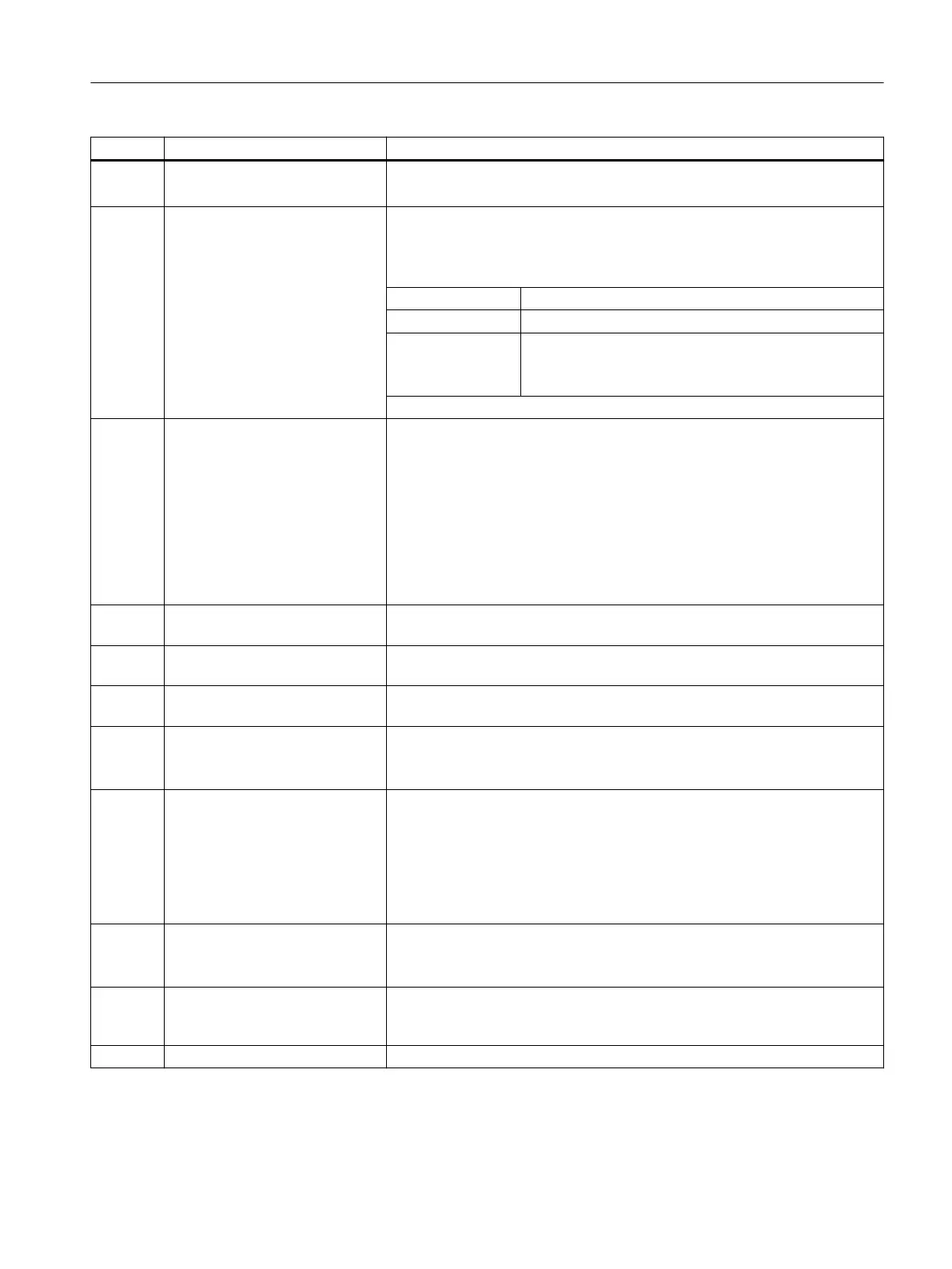

Number Cause Remedy

F01650 Acceptance test required Carry out an acceptance test and create test certicate.

Switch o the Control Unit and switch on again.

F01659 Write task for parameter rejected Cause: The converter should be reset to the factory setting. However, it is not

permissible to reset the safety functions as the safety functions are currently

enabled.

Remedy with operator panel:

p0010 = 30 Parameter reset

p9761 = … Enter password for the safety functions.

p0970 = 5 Reset start safety parameter.

The converter sets p0970=5 once it has reset the pa‐

rameters.

Then reset the converter to the factory setting again.

F01662 Error, internal communications

• Check the electrical cabinet design and cable routing for EMC compliance.

• Check whether an impermissible voltage is connected at one of the digital

outputs.

• Check whether a digital output is loaded with an impermissible current.

If the checks are unsuccessful:

• Switch o the converter power supply and switch it on again

• Upgrade the rmware

• Contact technical support

A01666 Static 1 signal at the F-DI for safe

acknowledgment

Set failsafe digital input F-DI to a logical 0 signal.

A01698 Commissioning mode active for

safety functions

This message is withdrawn after the Safety commissioning has ended.

A01699 Switch-o signal path test re‐

quired

After the next time that the "STO" function is deselected, the message is with‐

drawn and the monitoring time is reset.

A01900 PROFIBUS: Conguration tele‐

gram faulty

Explanation: A PROFIBUS master is attempting to establish a connection with

a faulty conguration telegram.

Check the bus conguration on the master and device side.

A01910

F01910

Fieldbus SS setpoint timeout The alarm is generated when p2040 ≠ 0 ms and one of the following causes is

present:

• The bus connection is interrupted

• The MODBUS master is switched o

• Communications error (CRC, parity bit, logical error)

An excessively low value for the eldbus monitoring time (p2040)

A01920 PROFIBUS: Cyclic connection in‐

terrupt

Explanation: The cyclic connection to PROFIBUS master is interrupted.

Establish the PROFIBUS connection and activate the PROFIBUS master with

cyclic operation.

F03505 Analog input, wire break Check the connection to the signal source for interrupts.

Check the level of the signal supplied.

The input current measured by the analog input can be read out in r0752.

A03520 Temperature sensor fault Check that the sensor is connected correctly.

Alarms, faults and system messages

9.5List of alarms and faults

SINAMICS G120C Converters

Operating Instructions, 02/2023, FW V4.7 SP14, A5E34263257B AK 373

Loading...

Loading...