Setup

3.1 Punching and nibbling tools

3-37

SINUMERIK 802D sl Operation and Programming Nibbling (BP-N), 06/2006 Edition

6FC5 398-3CP10-0BA0

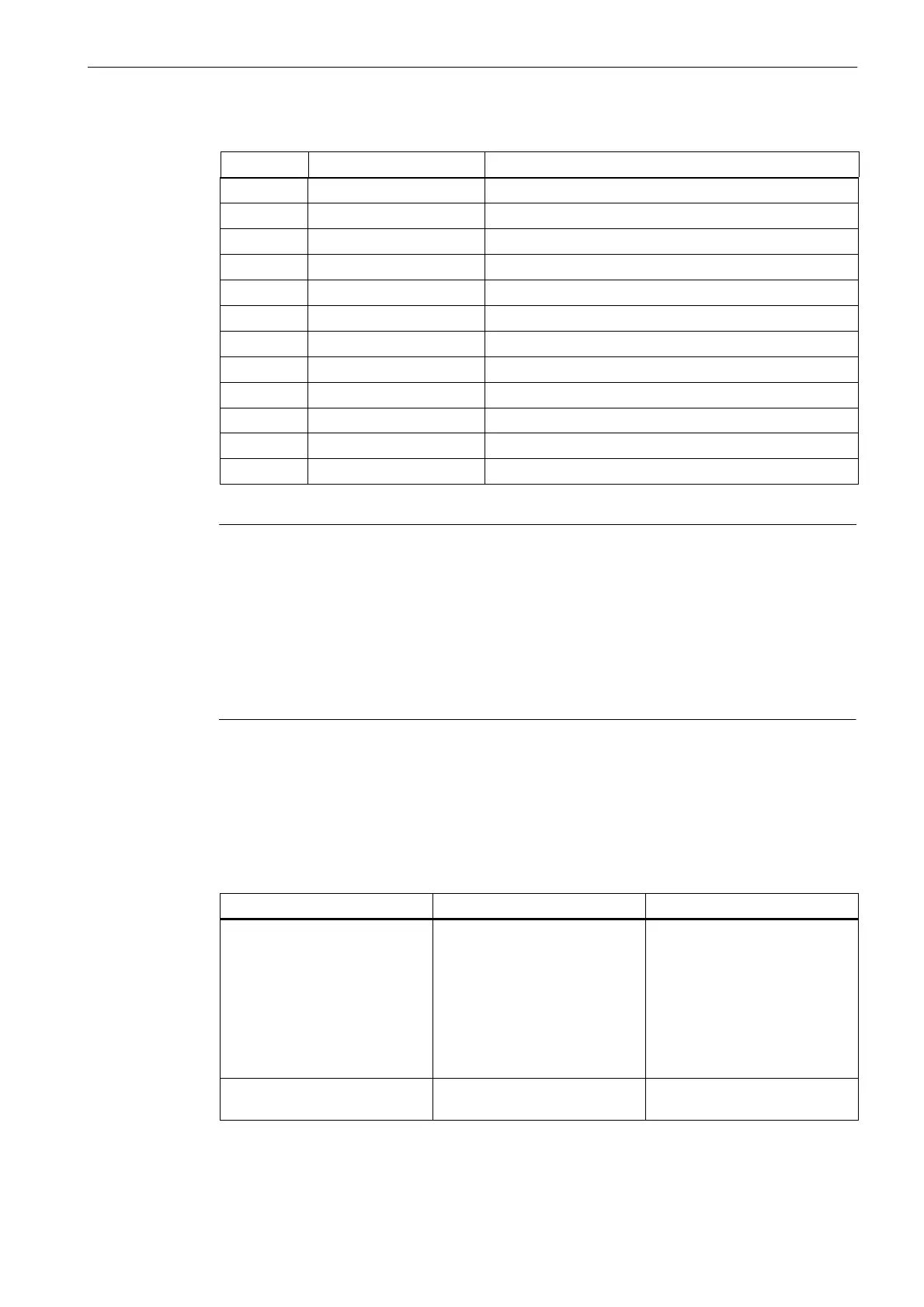

Table 3-2 Parameter list for nibbling, continued

Parameters DescriptionField

DP25 Sheet thickness Current sheet thickness

DPC1 Axis of the driven tool Tool orientation can be changed by way of rotary axis

DPC2 Location Tool location

DPC3 Maximum sheet thickness Maximum sheet thickness

DPC4 No. of the multi-tool Number of the toolholder

DPC5 DPC5 Free

DPC6 DPC6 Free

DPC7 DPC7 Free

DPC8 DPC8 Free

DPC9 DPC9 Free

DPC10 DPC10 Free

Important

The meanings of the DP2, DP6, DP12 and DP24 parameters is defined in conjunction with

part program simulation as follows:

S DP2 Reserved for part program simulation

S DP6 Tool geometry

S DP12 Angle of tool orientation

S DP24 Envelope diameter

and cannot be overwritten.

Interrelation between geometry data and cutting edge parameters

The geometry data required for the simulation of punching/nibbling tools can be mapped to

the cutting edge parameters as follows:

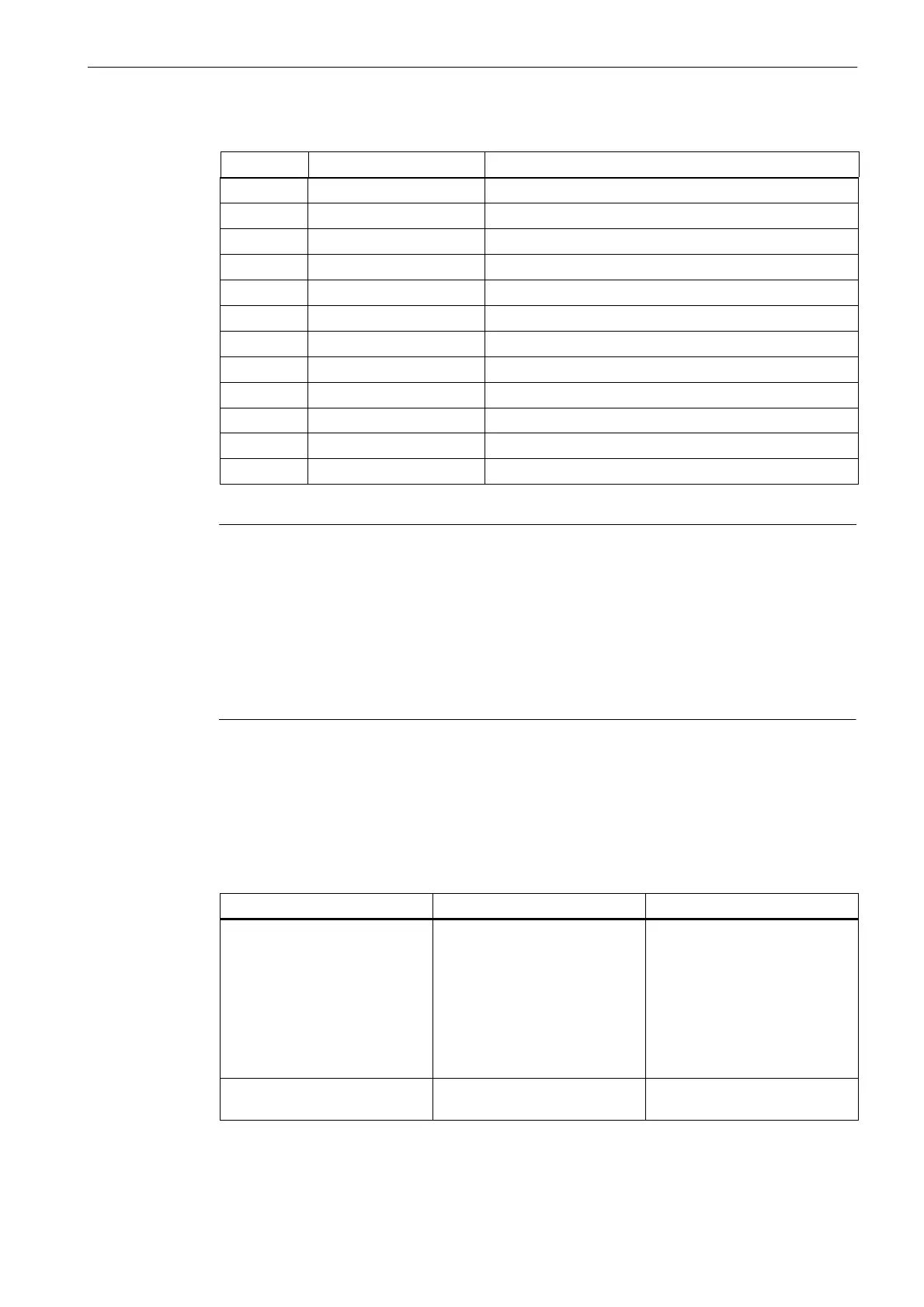

Table 3-3 Interrelation ’geometry data – cutting edge parameters’

Geometry

Tool geometry Cutting edge parameters

Round,

hexagon or octagon,

triangle,

double “D”,

single “D”,

long “D”,

rectangle,

square,

elongated hole

Envelope diameter

Orientation angle

DP24

DP12

Rectangle, square Y Length of the tool edge

X Length of the tool edge

DP8

DP9

Loading...

Loading...