Configuration

5-36 7SJ62 Manual

C53000-G1140-C121-1

Consistency check In addition to the sample configuration chart 1, shown in Figure 5-36, other configura-

tion sheets may exist. The contents of any particular configuration sheet is compiled

by DIGSI

®

4 into a program and processed by the protective device. For CFC charts

developed by the user, syntactic correctness can be verified by clicking the menu

command &KDUW, and then &KHFN&RQVLVWHQF\. The consistency check will deter-

mine if the modules violate conventions of various run-time levels, or any of the prin-

ciples below.

Check of functional correctness must be performed manually.

The completed CFC chart can be saved via menu item &KDUW, and &ORVH. Likewise,

the CFC chart may be reopened and edited by clicking on &KDUW, selecting the appro-

priate chart, and clicking on 2SHQ.

Please be aware, certain limitations exist, because of memory space and processing

power. The limits listed in Table 5-6 are generally applicable. The limits given in Table

5-7 are relay-specific. These limits must not

be exceeded because adverse effects to

the protective functionality (e.g. slower trip times) would result.

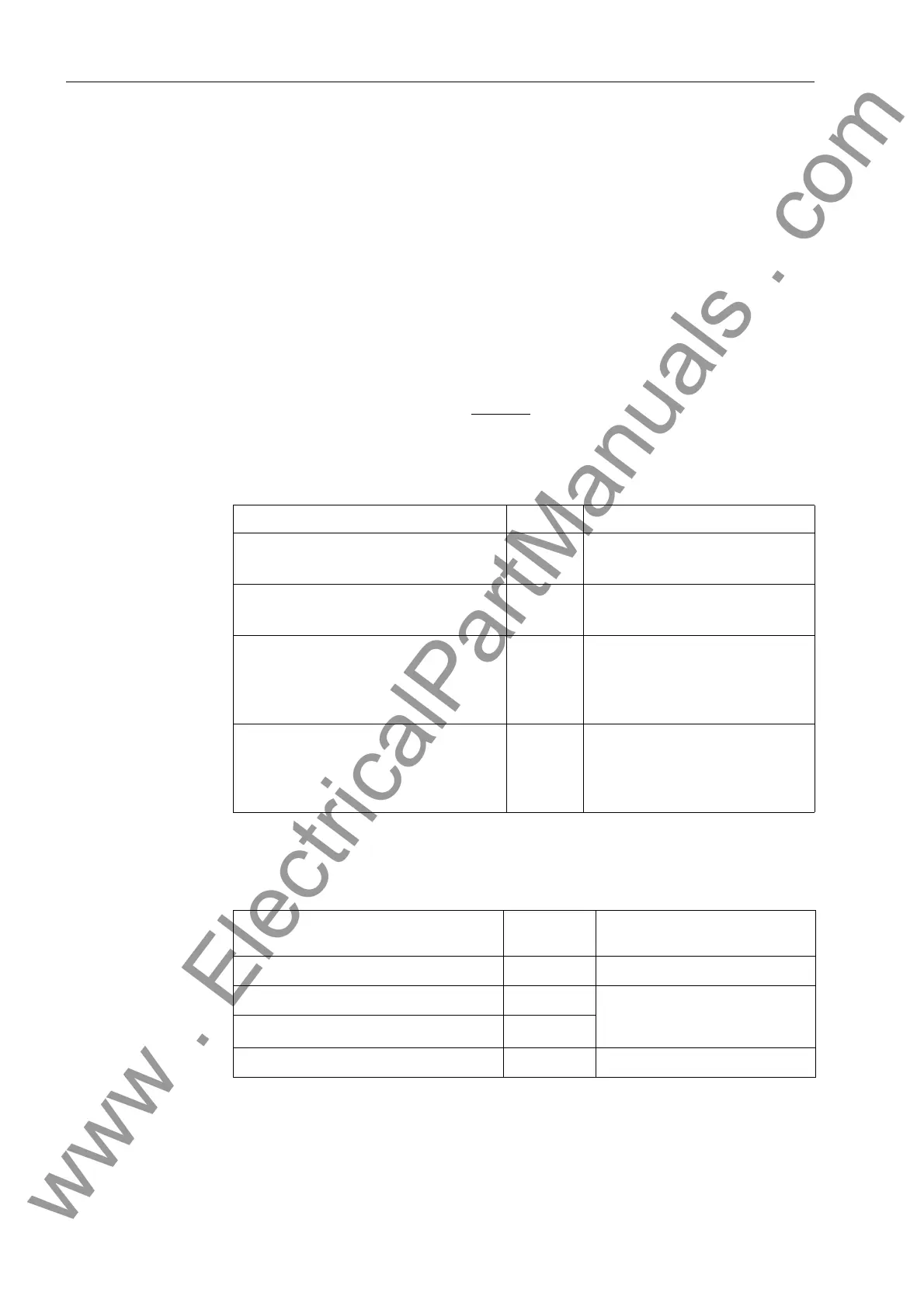

Table 5-7 Maximum Number of Modules per Process Area for SIPROTEC

®

7SJ62

The limits are monitored by the DIGSI

®

4 operating program. When 100 % of the al-

lowed memory is used, DIGSI

®

4 issues a warning message. See Figure 5-37.

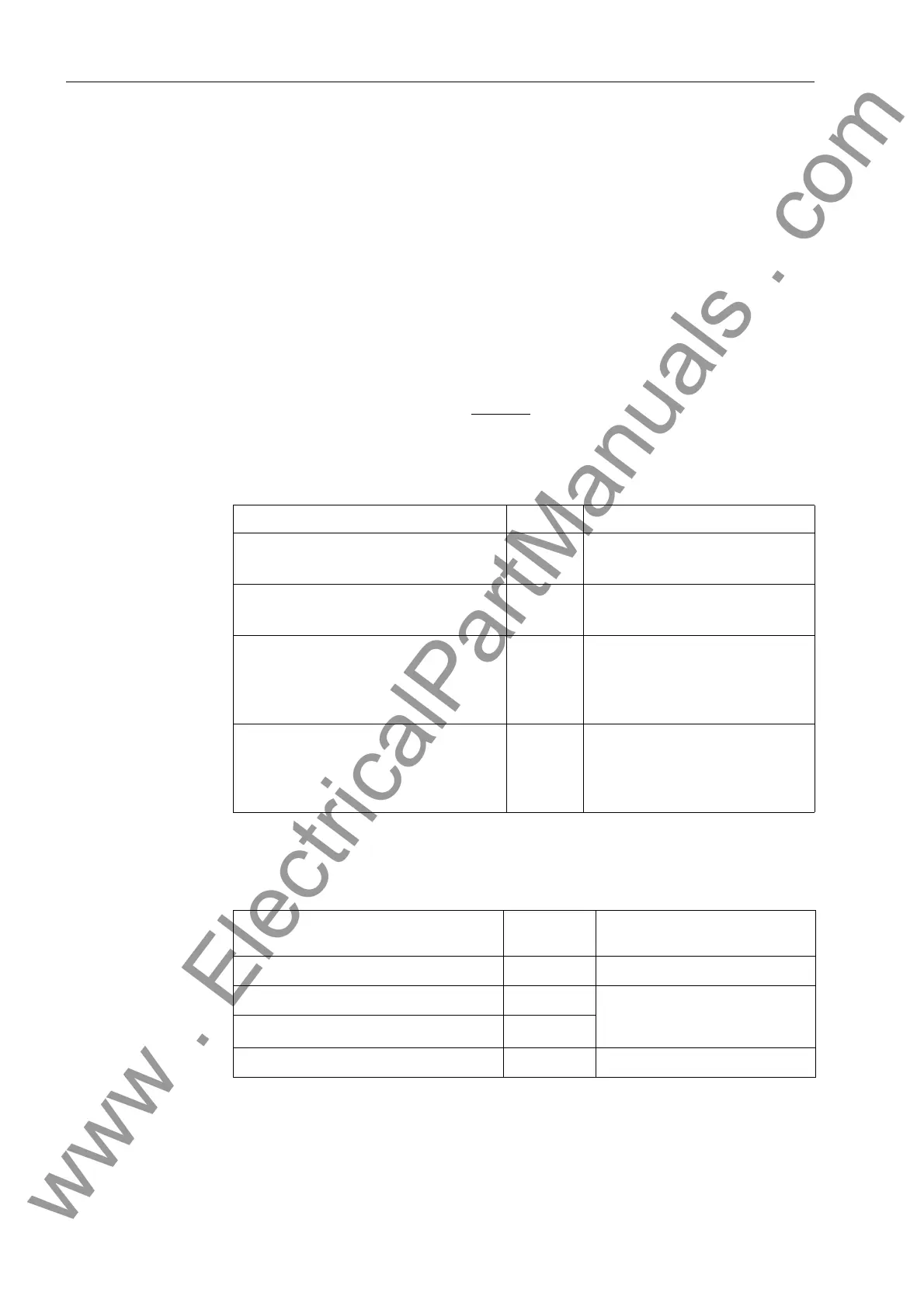

Table 5-6 Maximum Number of Charts and Inputs

Limit Description Limit Comment

Total number of all CFC charts for all

processing areas

32

Allowable number of CFC charts in a

single processing area

16

Total number of inputs on the left

panel for all CFC charts in event-

driven process areas

100

*

)

*) If a message is used in two charts, it counts as two.

Valid for process areas:

PLC1_BEARB (system logic)

PLC_BEARB (protective

functions)

Maximum number of different inputs

on the left panel for all CFC charts in

event-driven process areas

50 Valid for process areas:

PLC1_BEARB (system logic)

PLC_BEARB (protective

functions)

Process Area (running level) Number of

Blocks

Comment

MW_BEARB (Meter processing) < 100

PLC1_BEARB (Slow PLC Logic) approx 30

Depends on the type of functional

blocks used and the number of

connections

PLC_BEARB (Fast PLC Logic) approx 12

SFS_BEARB (Interlocking) < 100

www . ElectricalPartManuals . com

Loading...

Loading...