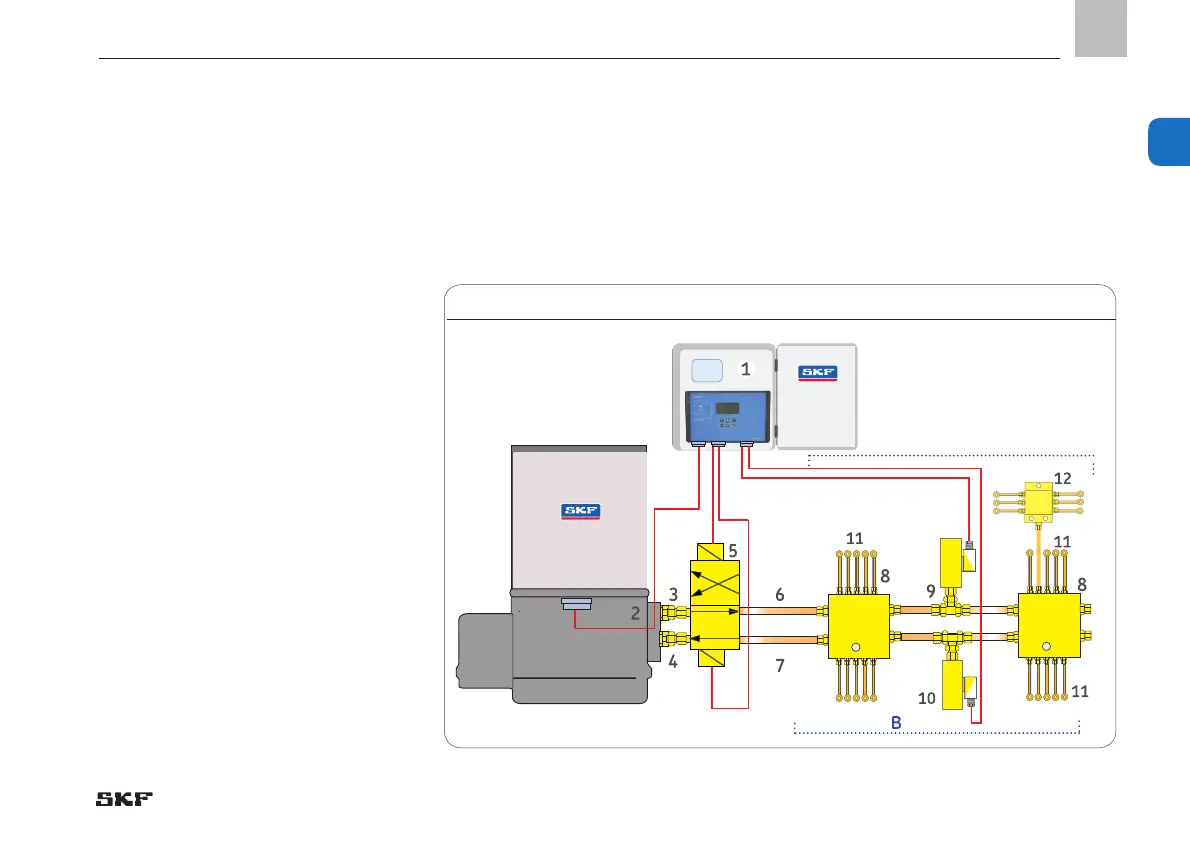

2. Overview/System description

)See Figure 3

The following description applies to a 230

VAC Dual Line centralized

lubrication system for industrial use with

one main line. Control unit LMC 301 (1) is

installed in a control cabinet, with load unit

and power supply for the pump motor and

for the attached valves and sensors.

One grease supply line (3) and one grease

return line (4) are flanged to the pump

housing (2) of the Dual Line pump. These

are flanged with their respective ends to an

electrical changeover valve (5).

Two main feed lines (6) (7) proceed from the

electrical changeover valve to the Dual Line

distributors in downstream alignment (8).

An analog pressure sensor (9) (10) has been

fitted ahead of each of the last Dual Line

distributors of main feed line 1 (A) and main

feed line 2 (B). The sensor transmits a signal

corresponding to the existing pressure to

the control unit (the control units compares

the two signals). Fill level monitoring is

performed by a fill level switch located in

the pump reservoir. This switches the pump

2.2 General design of a Dual Line centralized lubrication system with one main line with two analog pressure sensors

off when the minimum fill level has been

reached.

Example of a Dual Line Dual Line centralized lubrication system with one main line, Fig. 3

A

EN

19

2

Loading...

Loading...