9. Malfunctions, causes, and remedies

EN

86

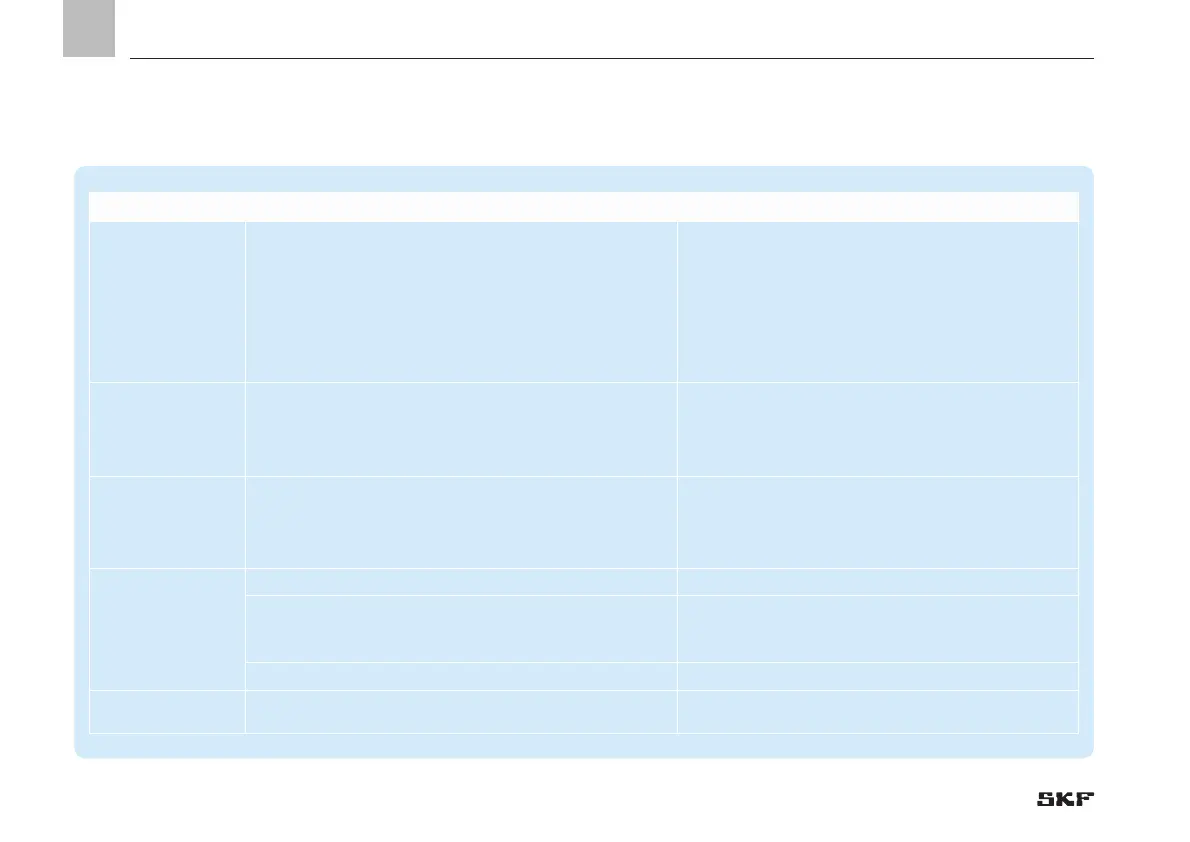

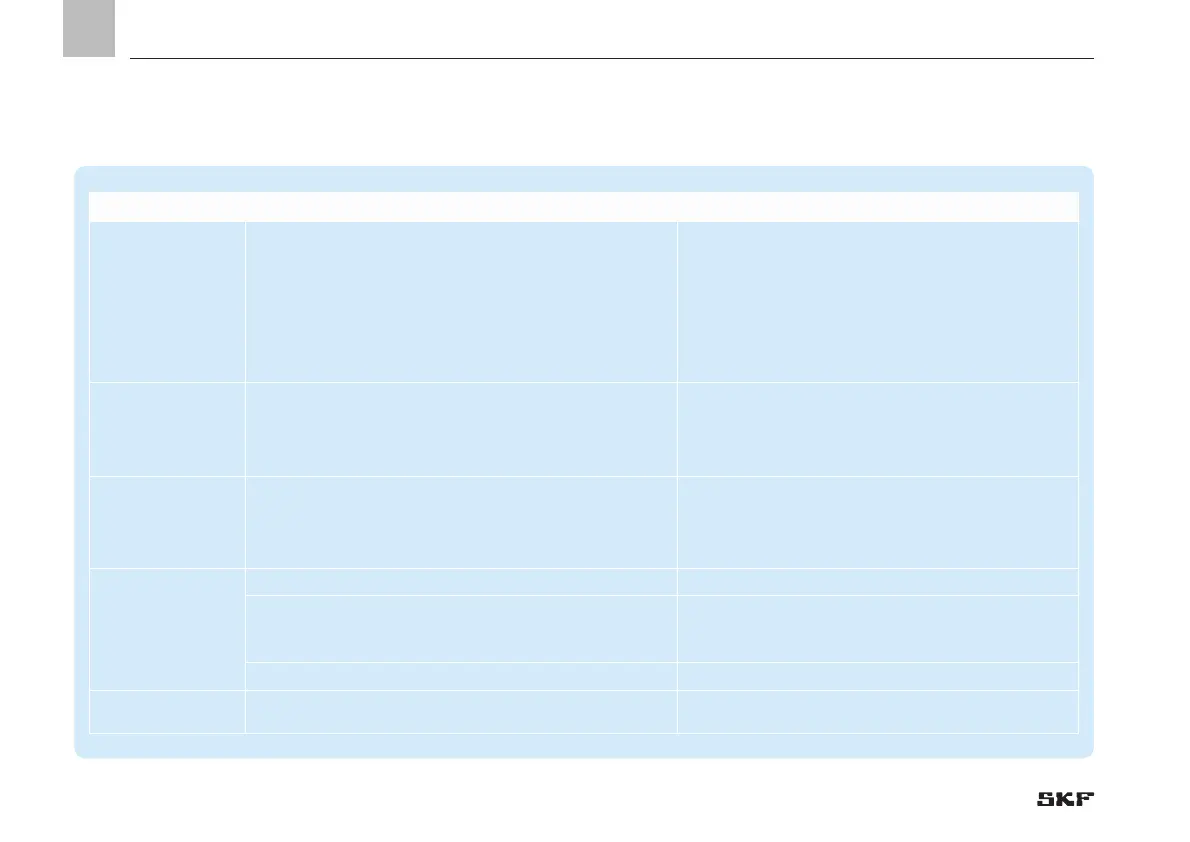

9.4 Dual Line control unit - Commissioning malfunctions

Malfunction Cause Remedy

Motor fails to start

when the operating

voltage is applied

o Motor incorrectly connected

o Pump timing not parameterized

• Check that motor connection is wired correctly

• Inspect pump timing as described in Chapter 6.3.1

Pump does not

switch off on

reaching minimum

fill level

o Fill level switch NC contact/NO-contact incorrectly

configured

• Check connection on fill level switch

No pressure

build-up

o Relief valve connected incorrectly

o Directional solenoid valves for zone(s) incorrectly

connected

o Pressure switch PT not/incorrectly connected

• Check that connections are wired correctly

No pressure relief

o Reversing valve not/incorrectly connected

o Directional solenoid valves for zone(s) not/incorrectly

connected

o Pressure switch PT not/incorrectly connected

o Relief valve does not work

• Inspect relief valve, replace if necessary

o Holding time too short (only with 2/2 directional

solenoid valves)

• Extend holding time

Loading...

Loading...