6. Configuration by operator/local admin

Design

The example applies to a Dual Line centralized

lubrication system with two zones (zone 1/

zone 2 (line 1/line 2)).

It is composed of the main components

Dual Line pump (1) with pressure-regu-

lating valve (2) and Dual Line feeders (15)

A main line (3) with a pressure switch (4) is

flanged to the pump and switches off the

pump once the set maximum pressure is

reached. The main line (3) connects the

pump outlet with the four 3/2 directional

solenoid valves for zone 1 (5/6) and zone 2

(7/8).

A model DDS50 differential pressure switch

(9 to 12) is fitted at the end of each line

ahead of the last feeder to monitor pressure/

changeover pressure.

Further, a piston detector is fitted on the last

feeders (13/14) to monitor the lubrication

cycles. Chapter 3 contains a general

functional description.

)See Figure 26 and Fig. 27

6.4.1 2-zone Dual Line centralized lubrication system with 3/2 directional solenoid valves and DDS50 differential pressure switch

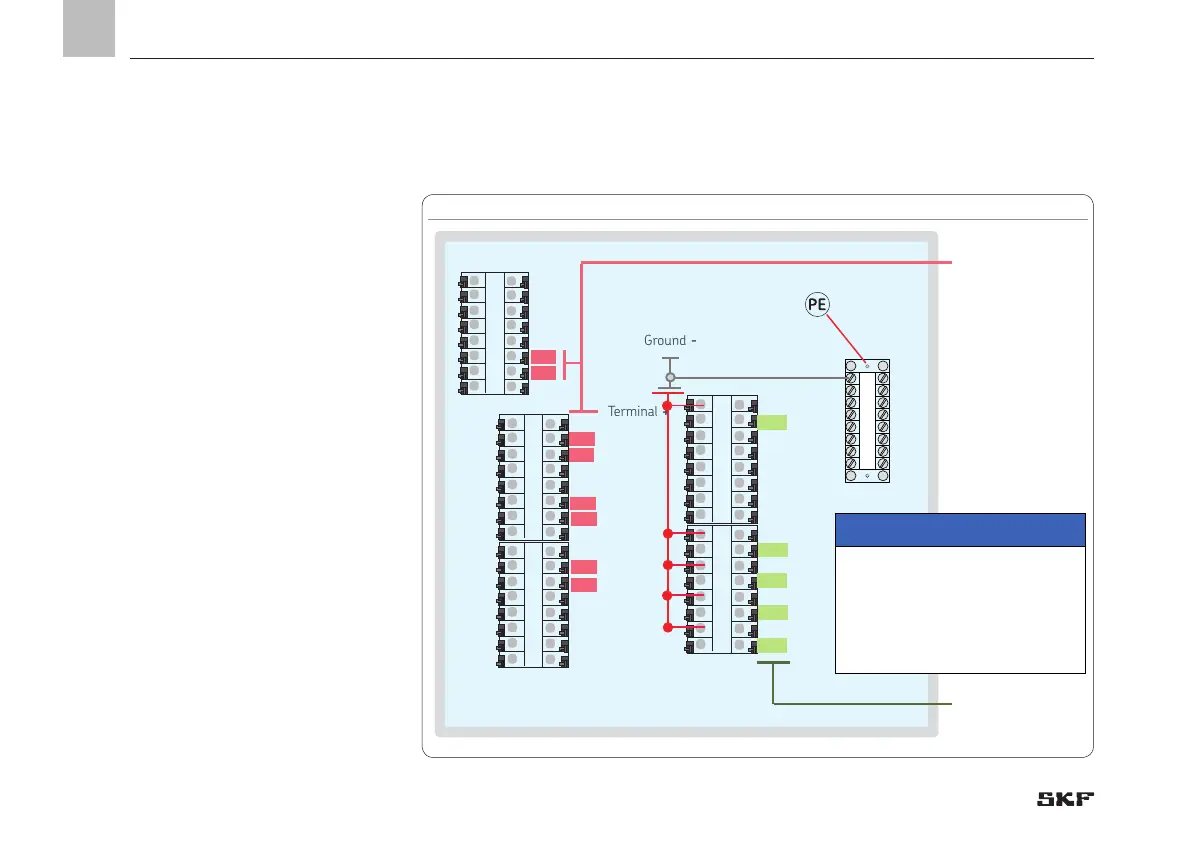

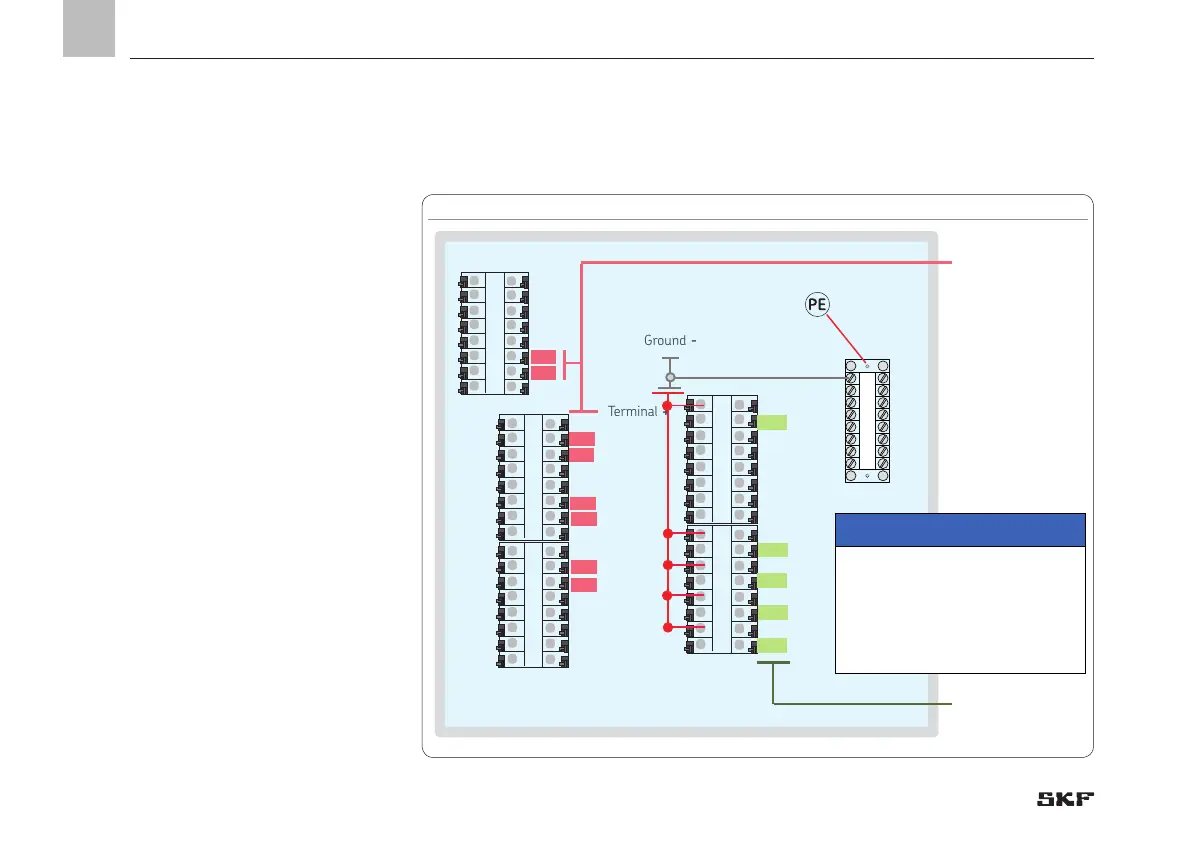

Terminal +

Ground -

Analog ports

to terminal strip X3 and

digital ports to terminal

strip X2

LMC 301, electrical terminal diagram, Fig. 25

I 4

I 3

I 5

I 6

I 7

I 8

I 1

I 2

Ø 1

Ø 2

Ø 3

Ø 4

Ø 8

IMPORTANT NOTE

Only one operating voltage (24 VDC or

230 VAC) can be connected to terminal

strip 4.1 or 4.2. Do not operate two

different voltages within a terminal strip!

EN

64

Use a PE terminal on valves

Loading...

Loading...