111

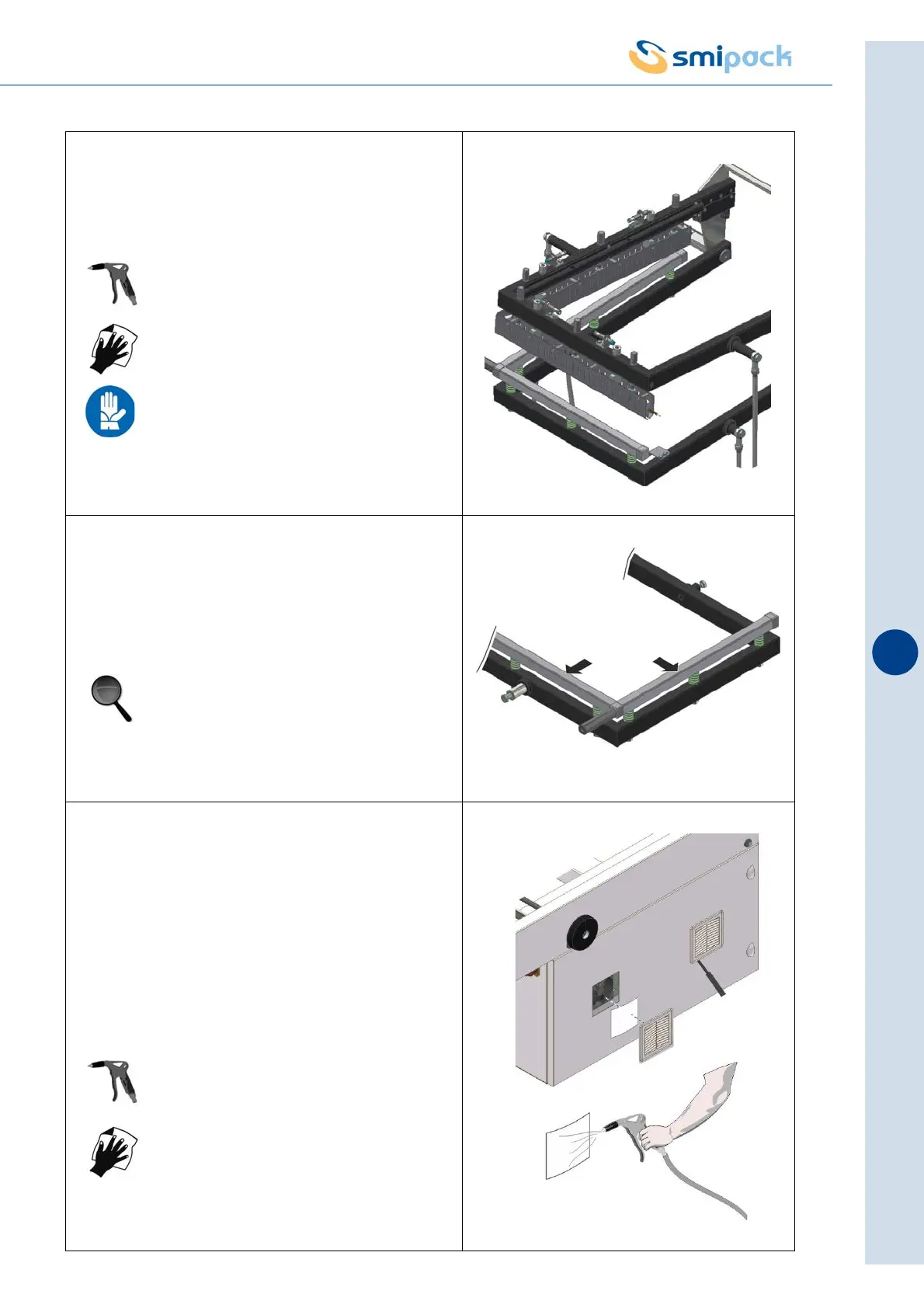

S10.6.2 - SEALING BAR

MACHINE STATUS: machine in stop

FREQUENCY: daily

Clean the sealing bar first of all with

compressed air. Then, while it is still hot,

remove leftover film with a moist cloth

paying attention to the cutting blade.

Note: Use protective gloves to prevent

burns.

S10.6.3 - CHECKING THE INTEGRITY OF THE

EXTERNAL PTFE LAYER

MACHINE STATUS: machine in stop

FREQUENCY: daily

Check how worn the external PTFE is on

the sealing bar contrast. If necessary,

change the PTFE as described in sheet

S10.7.4.

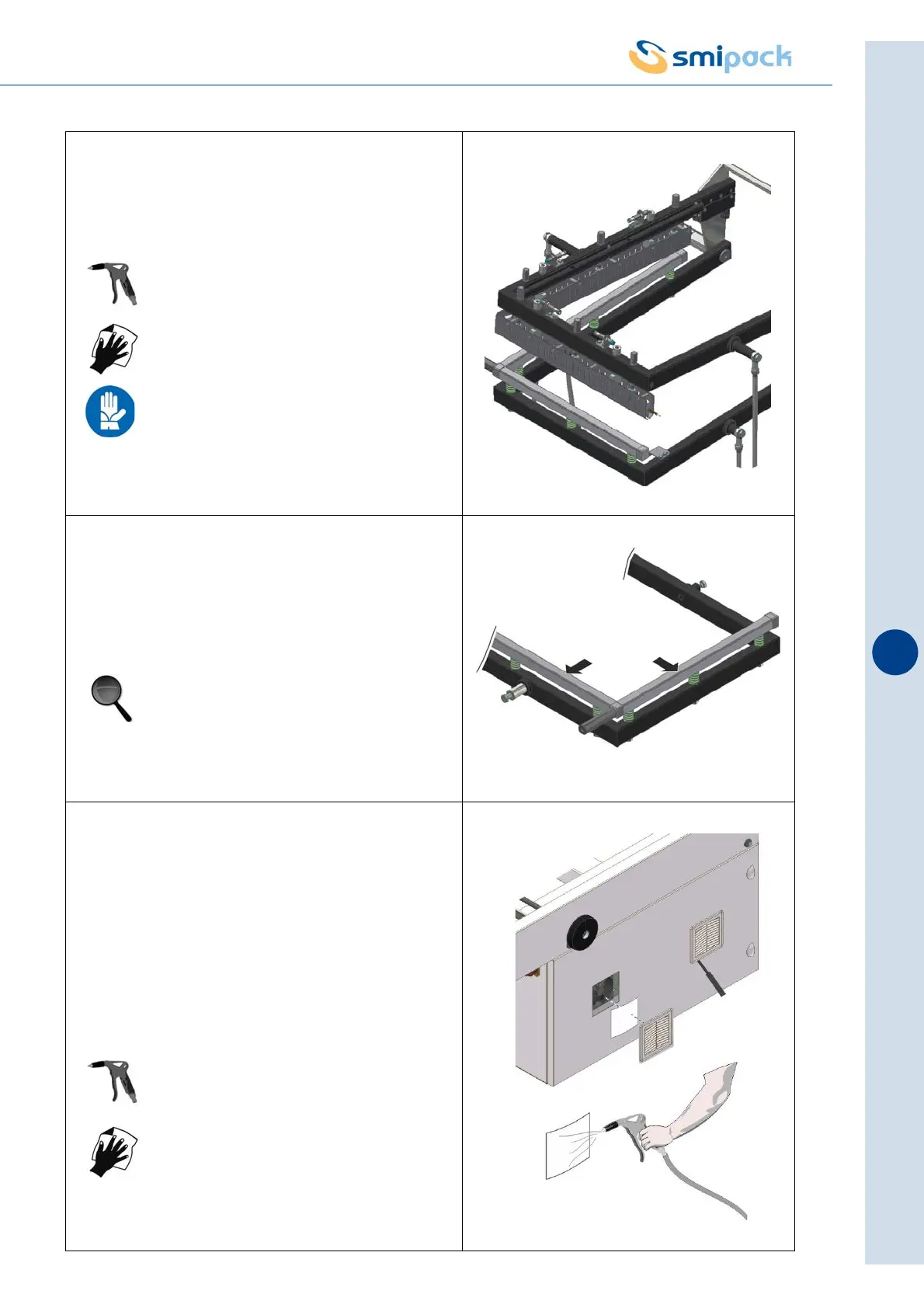

S10.6.4 - CLEANING THE ELECTRIC PANEL

FILTERS

MACHINE STATUS: machine in stop

FREQUENCY: monthly or less intervals

depending on the environmental pollution

REQUIRED MATERIAL: screwdriver, compressed

air gun, cloth

PROCEDURE:

Use a screwdriver on the point shown in

the figure to lever off the cover.

Remove the filters and clean each one by

means of a compressed air gun or if are

very dirty proceed to replace them.

Loading...

Loading...