FuelPump(MachinewithKubotaGasolineEngine)

TheelectricfuelpumpassemblyusedonmachineswithaKubotagasoline

engineisacombinationpositivedisplacementfuelpumpandafuellevelsending

unit.Thefuelpumpassemblyprovidespressurizedfueltotheenginefuelrail

inareturn-lesssystemandincludesaregulatortomaintainfuelpressureof

approximately276kPa(40psi).Thefuelpump/senderassemblyisattachedto

thetopofthefueltank.

Electricalpowerforthefuelpumpisavailablewhenthefuelpumprelayis

energizedbytheengineECU.Thefuelpumpelectricalcircuitisprotectedbya

15Afusethatislocatedintheenginepowercenter.

Note:WhenthekeyswitchisturnedtoON/RUN,theengineECUenergizesthe

fuelpumprelayforapproximately3secondswhichallowsthefuelsystemtobe

pressurized.Oncetheengineisrunning,thefuelpumprelayisalwaysenergized.

TestingtheFuelPump

1.Parkthemachineonalevelsurface,lowerthecuttingunits,shutoffthe

engine,andsettheparkingbrake.Removethekeyfromthekeyswitch.

Raiseandsupportthehood.

CAUTION

Thefuelsupplyhosewillcontainpressurizedfuel.Becarefulwhen

disconnectingfuelsupplyhose.Wipeupanyspilledfuelbefore

startingtheengine.

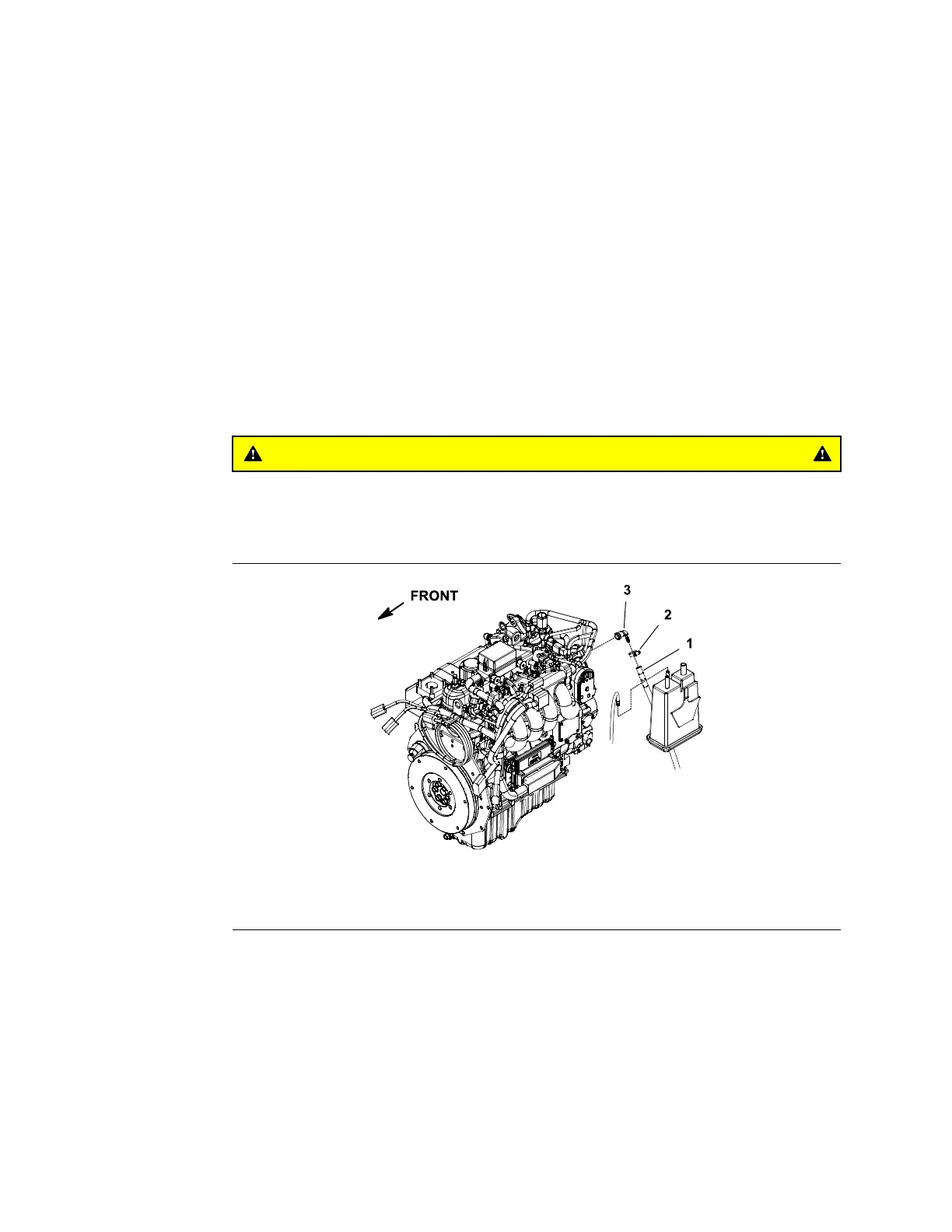

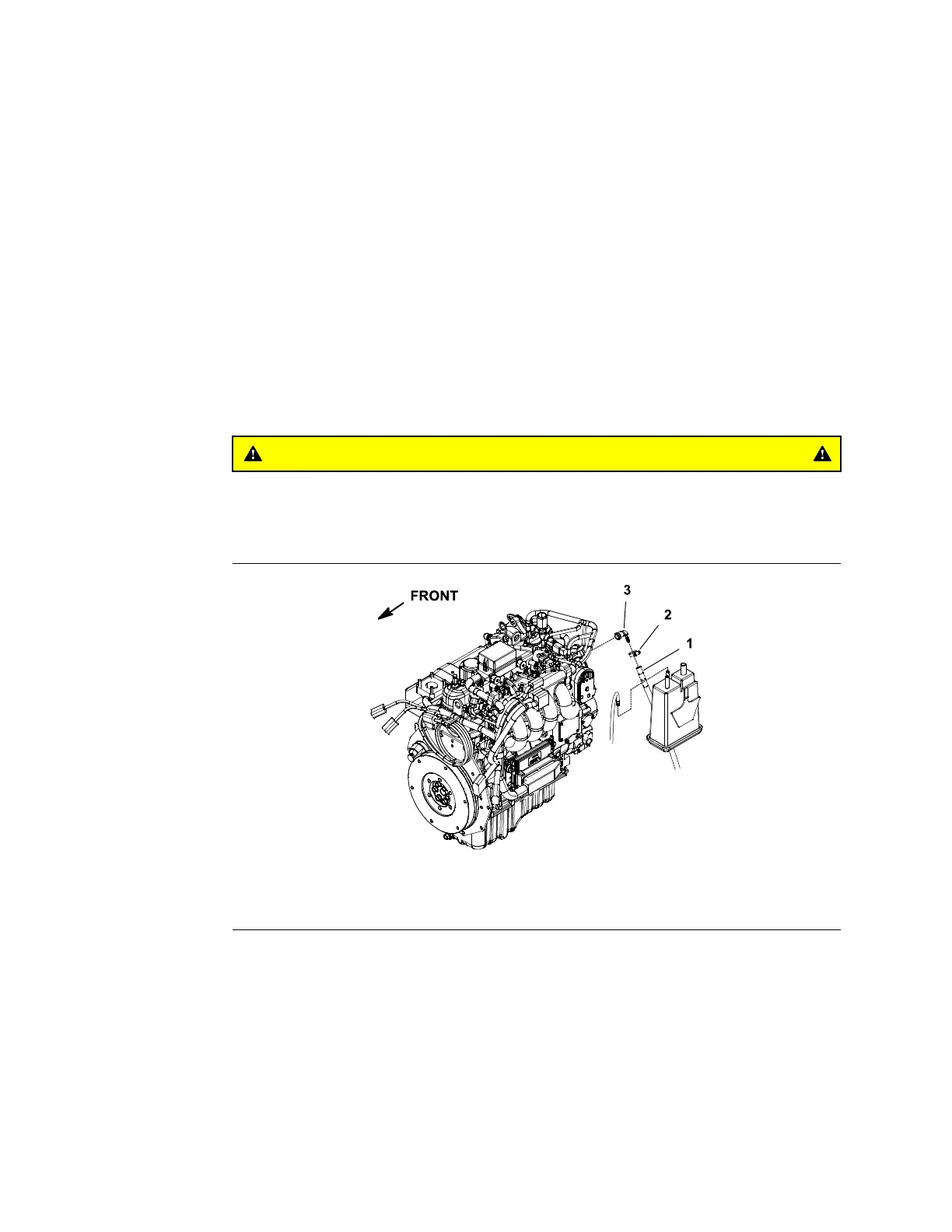

g228840

Figure278

1.Fuelsupplyhose2.Hoseclamp

3.Fueltting

2.Loosenhoseclampthatsecuresfuelsupplyhosetofuelttingonenginefuel

rail.Carefullydisconnectfuelsupplyhosefromfueltting(Figure278).

3.Installafuelpressuregaugecapableofmeasuring350kPa(50psi)tothe

disconnectedhose.

4.Whilemonitoringpressuregauge,turnkeyswitchtoON/RUN(donotstart

engine)sothatthefuelpumprelayandfuelpumpareenergized.The

fuelpressuredisplayedonthegaugeshouldrise.Afterpumprelayis

de-energized(approximately3seconds),turnkeyswitchtoOFFandthen

backtoON/RUN(donotstartengine)tore-energizethefuelpumprelayand

fuelpump.Fuelpumppressureshouldbeapproximately276kPa(40psi).

ElectricalSystem:TestingtheElectricalComponents

Page7–112

Reelmaster

®

5410/5510/5610Series

15216SLRevC

Loading...

Loading...