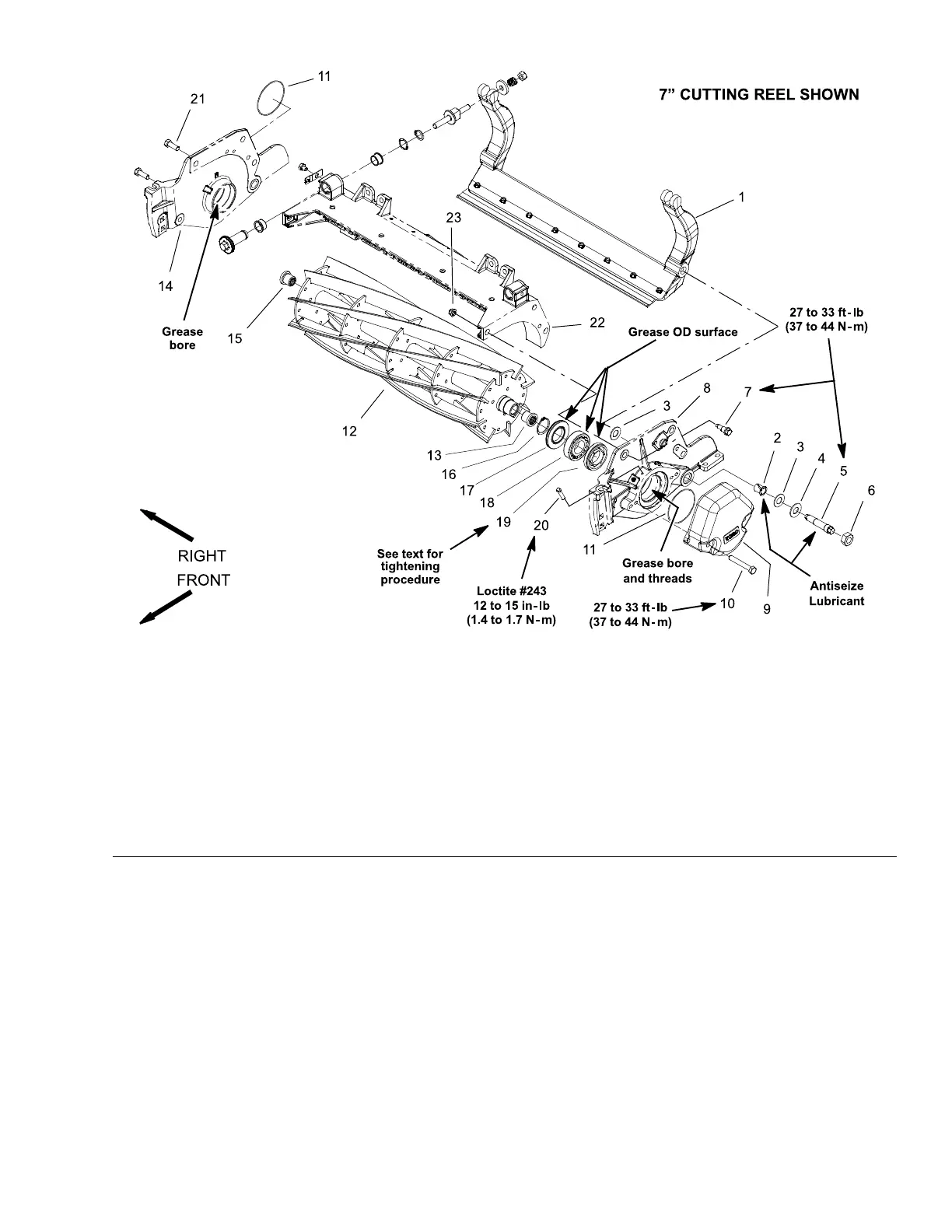

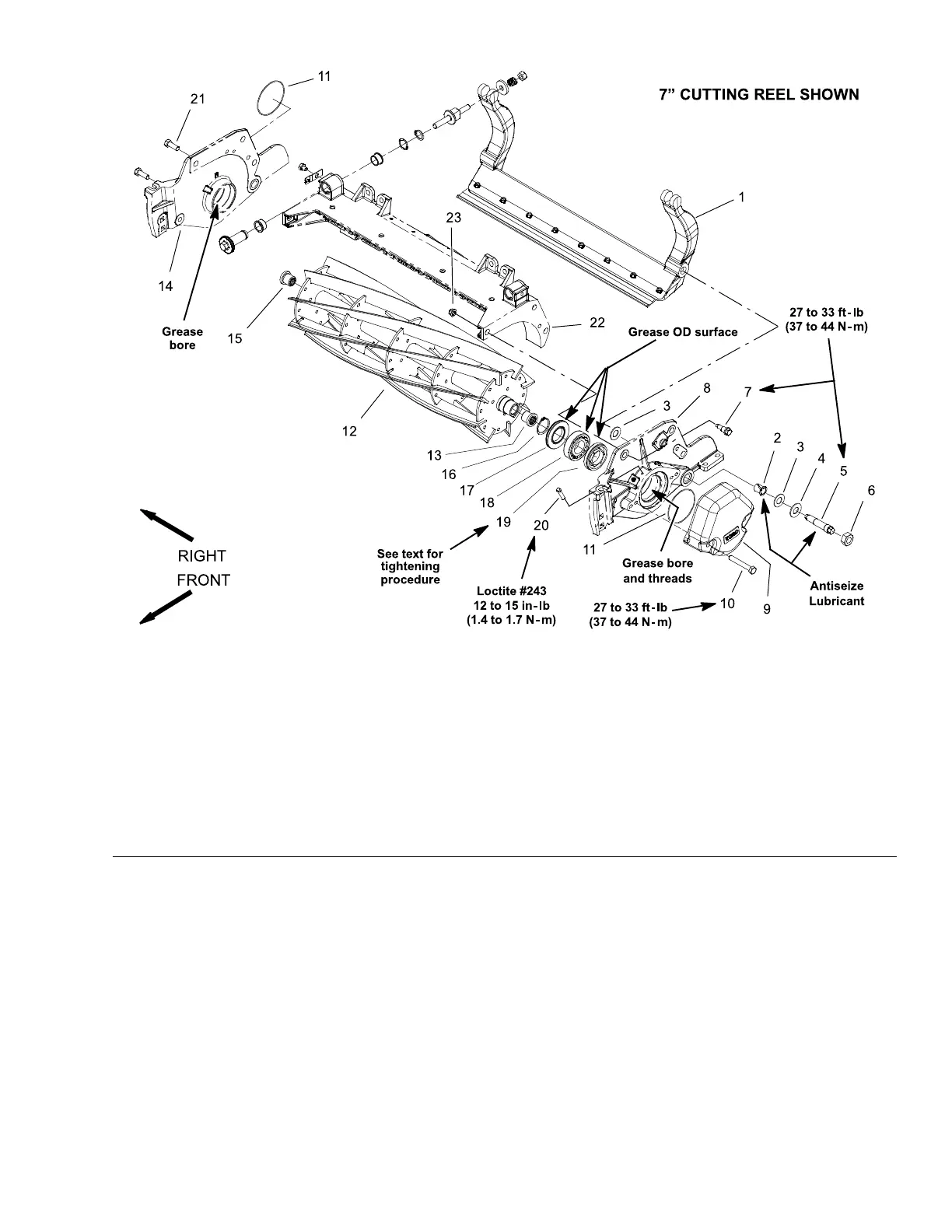

ReelAssembly(cuttingunitswithpaintedsideplates)

g214498

Figure339

1.Bedbarassembly9.Weight

17.Greaseseal(2each)

2.Flangebushing(2each)10.Capscrew(2each)18.Bearing(2each)

3.Plasticwasher(4each)11.O-ring

19.Bearingadjusternut

4.Metalwasher(2each)12.Cuttingreel

20.Setscrew

5.Bedbarpivotbolt(2each)13.Splineinsert(left-handthread)21.Capscrew(2each)

6.Locknut(2each)

14.RHsideplate

22.Cuttingunitframe

7.Shoulderbolt(3persideplate)15.Splineinsert(right-handthread)23.Flangenut(3persideplate)

8.LHsideplate

16.Retainingring(2each)

Note:Thissectionprovidestheprocedureforremovingandinstallingthecutting

reelassembly(cuttingreel,splineinserts,greasesealsandbearings)fromthe

cuttingunit.

Note:RefertoReelAssemblyService(cuttingunitswithpaintedsideplates)

(page9–33)forinformationonreplacingcuttingreelgreaseseals,bearings

andsplineinserts.

Note:RemovalofthecuttingreelrequiresremovaloftheLHsideplatefrom

thecuttingunitframe.TheRHsideplatedoesnothavetoberemovedfrom

theframe.

RemovingtheReelAssembly

1.Parkthemachineonacleanandlevelsurface,lowerthecuttingunits,shut

offtheengine,settheparkingbrake,andremovethekeyfromthekeyswitch.

Reelmaster

®

5410/5510/5610Series

Page9–29

CuttingUnit:ServiceandRepairs

15216SLRevC

Loading...

Loading...