ReelAssemblyInstallation(continued)

13.Installthebedbarassembly;refertoInstallingtheBedbarAssembly(page

9–21).

14.Adjustthecuttingunit;refertotheCuttingUnitOperator’sManual.

Note:Theparallelpositionoftherearrollertothecuttingreeliscontrolledby

theprecisionmachinedframeandsideplatesofthecuttingunit.Ifnecessary,

thecuttingunitsideplatescanbeloosenedandaslightadjustmentcanbe

madetoparalleltherearrollerwiththecuttingreel;refertoLevelingthe

RearRoller(page9–15).

15.Installaccessoriesifequipped.RefertoServiceandRepairs(page10–6)

foradditionalbeltdrivengroomerinformation.RefertoServiceandRepairs

(page11–4)foradditionaluniversalgroomerinformation.RefertoRear

RollerBrush–Optional(cuttingunitswithaluminumsideplates)(page9–57)

foradditionalrearrollerbrushinformation.

16.Ifcounterweightwasremovedfromcuttingunit,installnewO-ringoncounter

weight.Securecounterweighttocuttingunitsideplatewithtwo(2)ange

nuts.T orquescrewsfrom37to44N∙m(27to33ft‐ ‐

‐

lbs).

17.installcuttingunittothemachine.

ReelAssemblyService(cuttingunitswithaluminumsideplates)

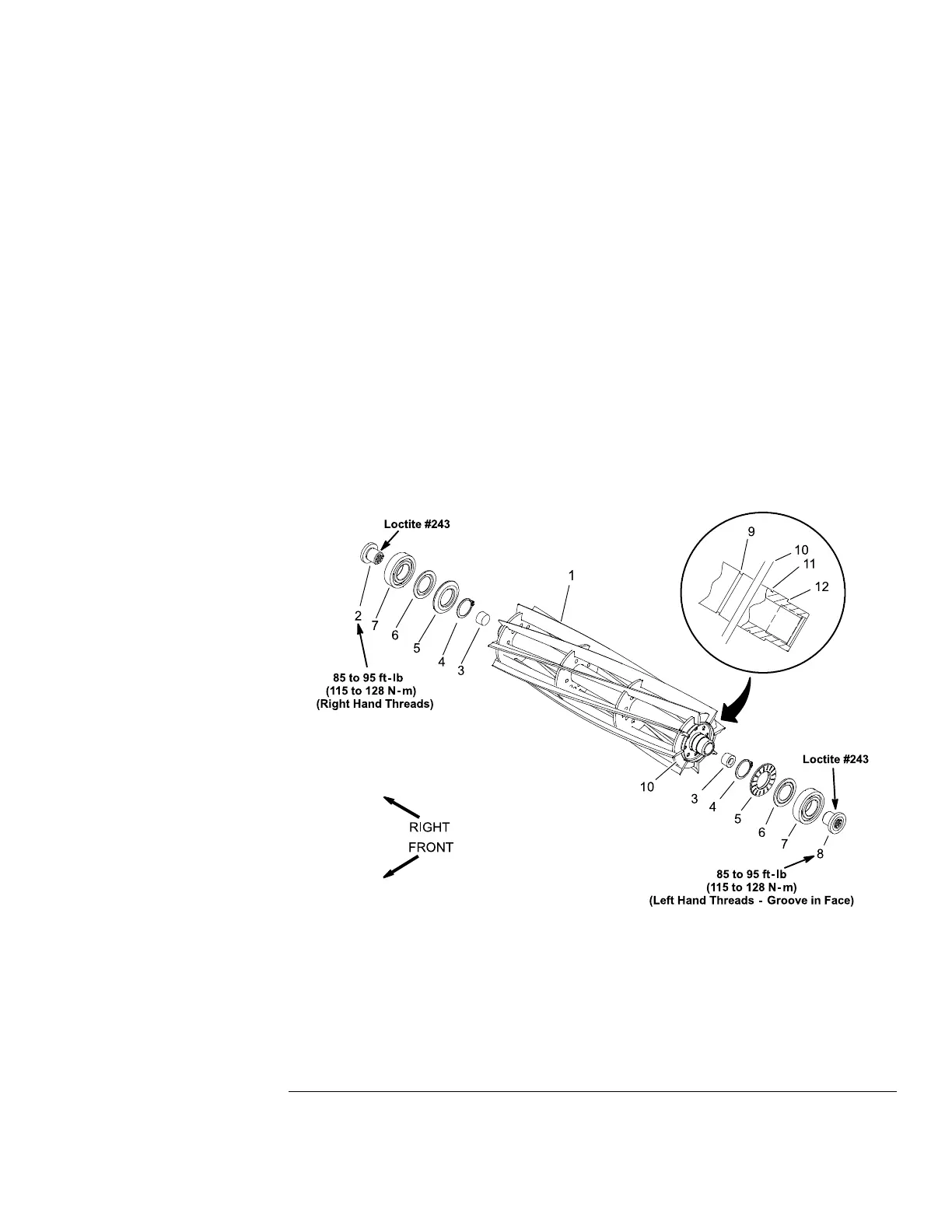

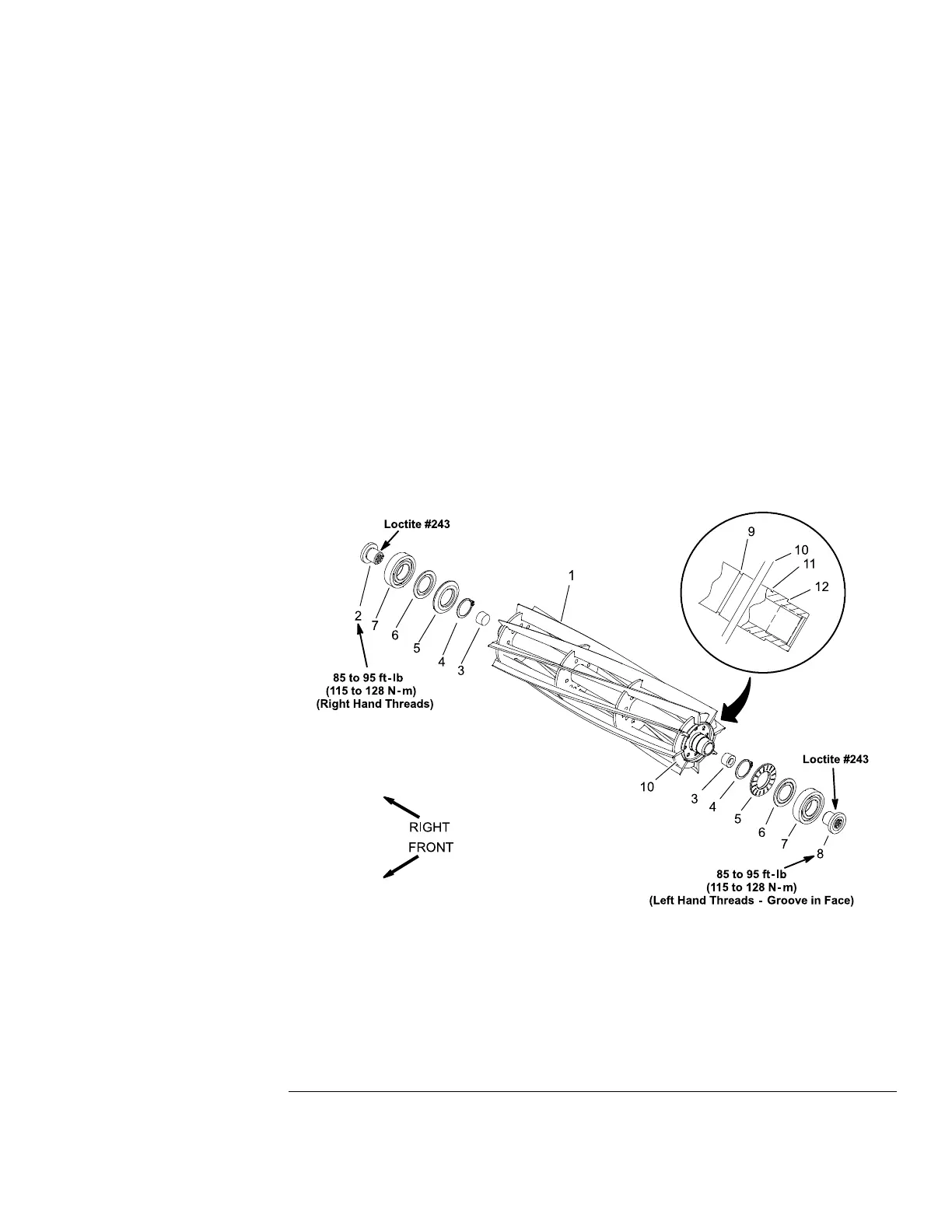

g230065

Figure345

1.Cuttingreel7.Sealedbearing(2each)

2.Threadedinsert(righthandthread)8.Threadedinsert(lefthandthreads)

3.Plasticplug(2each)9.Grooveindicatinglefthandthreads

4.Retainingring(2each)

10.Reelspider

5.Specialwasher(2each)

11.Retainingringgroove

6.Flockedseal(2each)

12.Bearingshoulder

Reelmaster

®

5410/5510/5610Series

Page9–39

CuttingUnit:ServiceandRepairs

15216SLRevC

Loading...

Loading...