03/2003

3-10

8850/ 510DP

PQ 1, PQ 2

Print Quality

PQ 1 Background PQ 2 Dark Bands

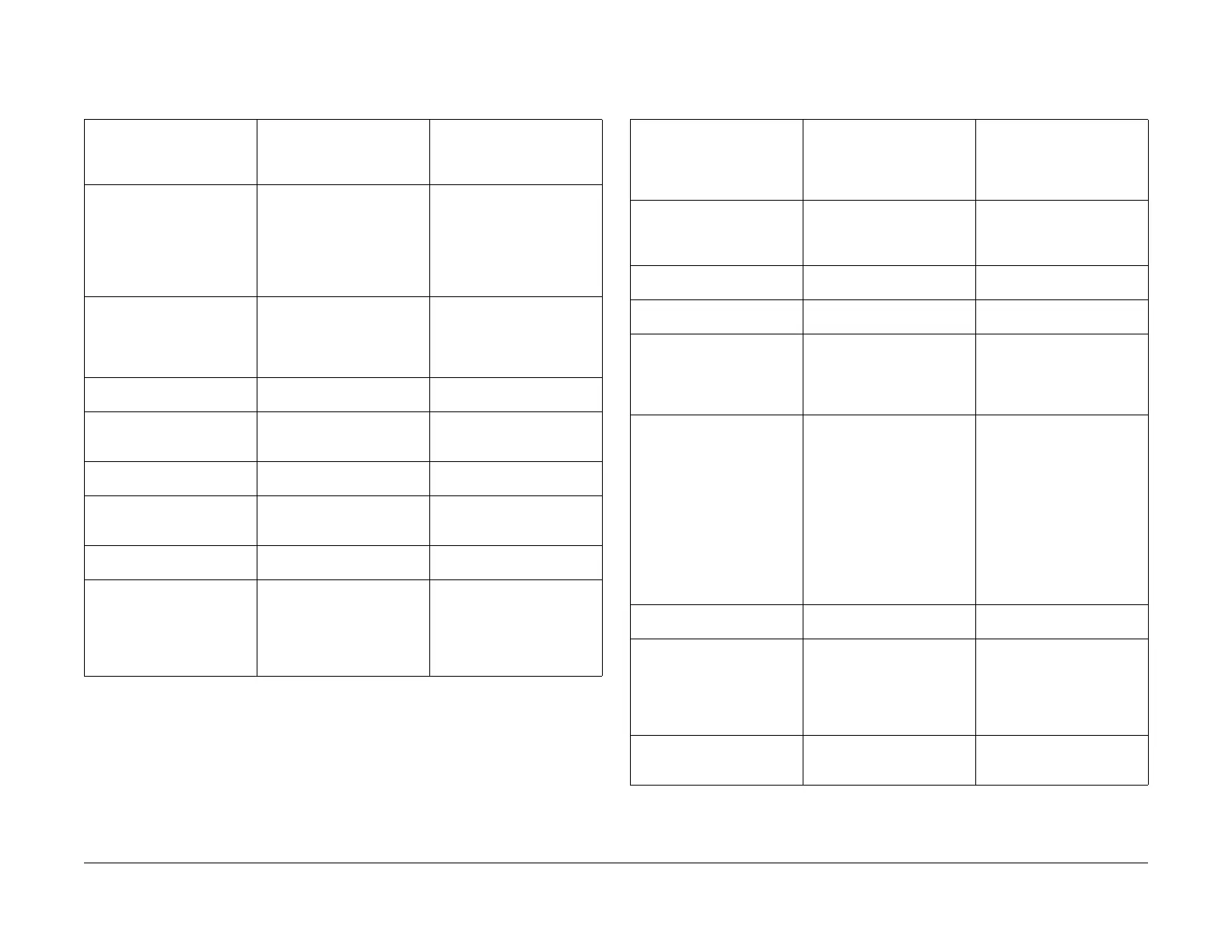

Table 1 Background Symptom / Check

Symptom / check

Contamination of the blank

area by toner particles on the

print

Probable Cause Corrective Action

1. An incorrect electrostatic

value

1A. Perform Electrostatic

Series (ADJ 9.2).

1B. Perform GP 1 Xero-

graphic HVPS Checkout Pro-

cedure.

1C. Clean/Replace/Repair

the corotrons.

2. Developer Bias incorrect. 2A. Perform Electrostatic

Series (ADJ 9.2).

2B. Perform GP 1 Xero-

graphic HVPS Checkout Pro-

cedure.

3. Toner concentration too

high.

3. Perform Image Density

(ADJ 9.3).

4. Erase Bar operation. 4. Refer to BSD 9.6 and

check for correct operation of

the Erase Bar.

5. Defective Cleaner Blade 6. Replace the Cleaner Blade

(REP 9.4).

6. Web Oil system not operat-

ing correctly.

7. Refer to BSD 10.2 and

check Web Oil system for cor-

rect operation.

7. Contaminated or defective

Drum.

8. Replace the Drum (REP

9.3).

9. Site environment is hot and

humid.

9A. Install Developer Heater

Kit

9B. Perform General Proce-

dure GP 8 Toner Control Sys-

tem Calibration and set for

humidity greater than 65%.

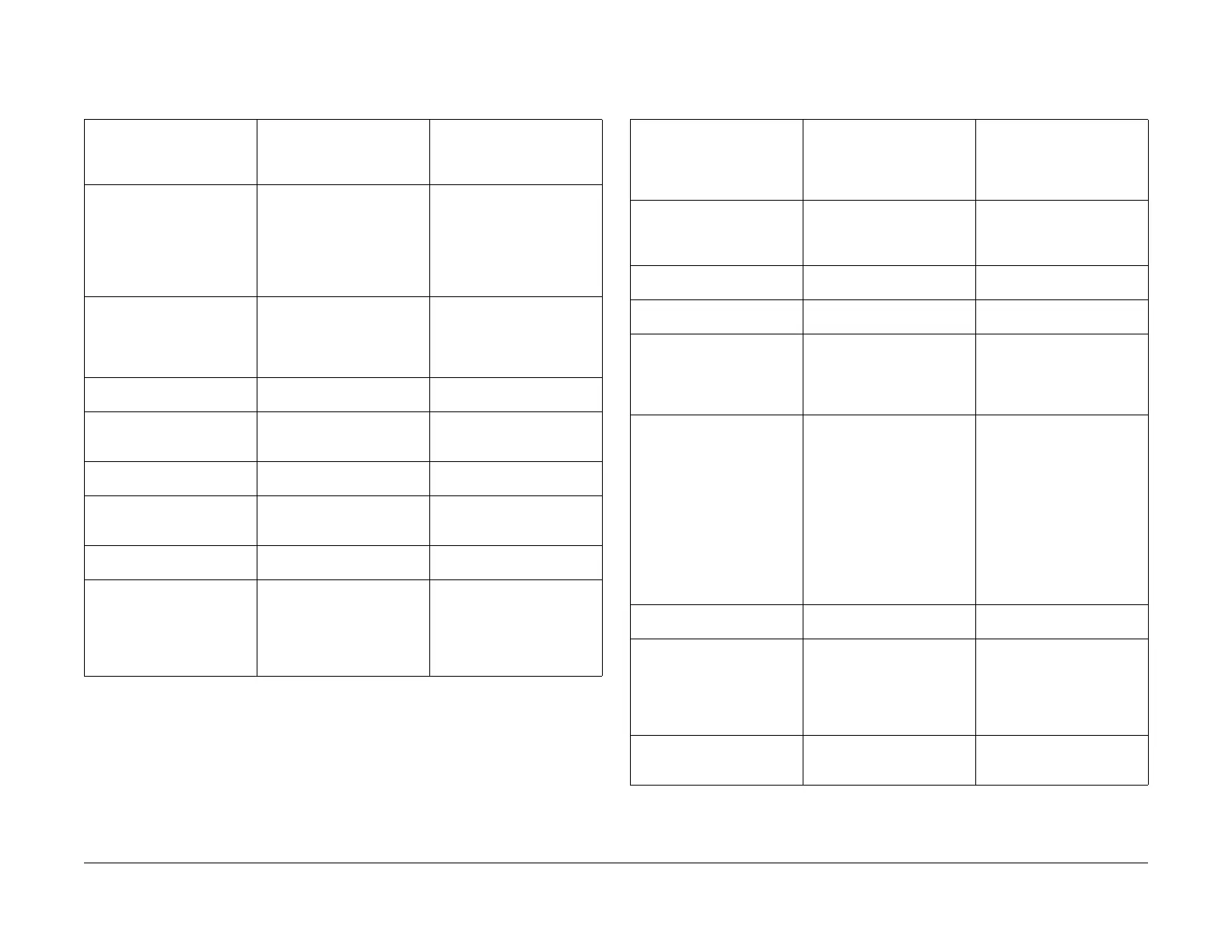

Table 1 Bands Symptom / Check

Symptom/ checks

Bands are 1 mm or more wide

and are in the media feed

direction. High density bands

are called black lines.

Probable Cause Corrective Action

1. Contaminated charge

scorotron

Detack Corotron contami-

nated.

1. Clean / replace screen /

pins (REP 9.8).

2. Defective Cleaner Blade 2. Replace the Cleaner Blade

(REP 9.4).

3. Contaminated magnetic

roll.

3. Check for foreign objects

on the mag roll.

4. Incorrect Electrostatic

value.

4B. Perform Electrostatic

Series (ADJ 9.2).

4C. Perform GP 1 Xero-

graphic HVPS Checkout Pro-

cedure.

5. Toner cloud from the Devel-

oper Module contaminating

the Drum and corotrons.

5A. Ensure that the Pressure

Equalizer Tubes are clean

(REP 9.18).

5B. Check for toner buildup on

the lower edge of the Devel-

oper Housing.

5C. Check that the Toner Dust

Trap, Tubes are not plugged.

Replace as required (PL

9.10).

5D. Check/Replace the Toner

Filter (PL 9.10).

6. Contaminated or defective

Drum.

7. Replace the Drum (REP

9.3).

7. Image Module LEDs oper-

ating incorrectly.

8. Enter [9-21-5] and check for

correct operation. (Refer to

BSD 6.1 and check for correct

electrical connections to/from

the Receiver PWB and the

LED Image Bar).

8. Photoreceptor Drive Motor

Encoder not installed or oper-

ating correctly.

Check at the Encoder is

installed correctly (REP 9.23).

Replace the Encoder (PL 9.1).

Loading...

Loading...