7.4 Trial Operation

7-21

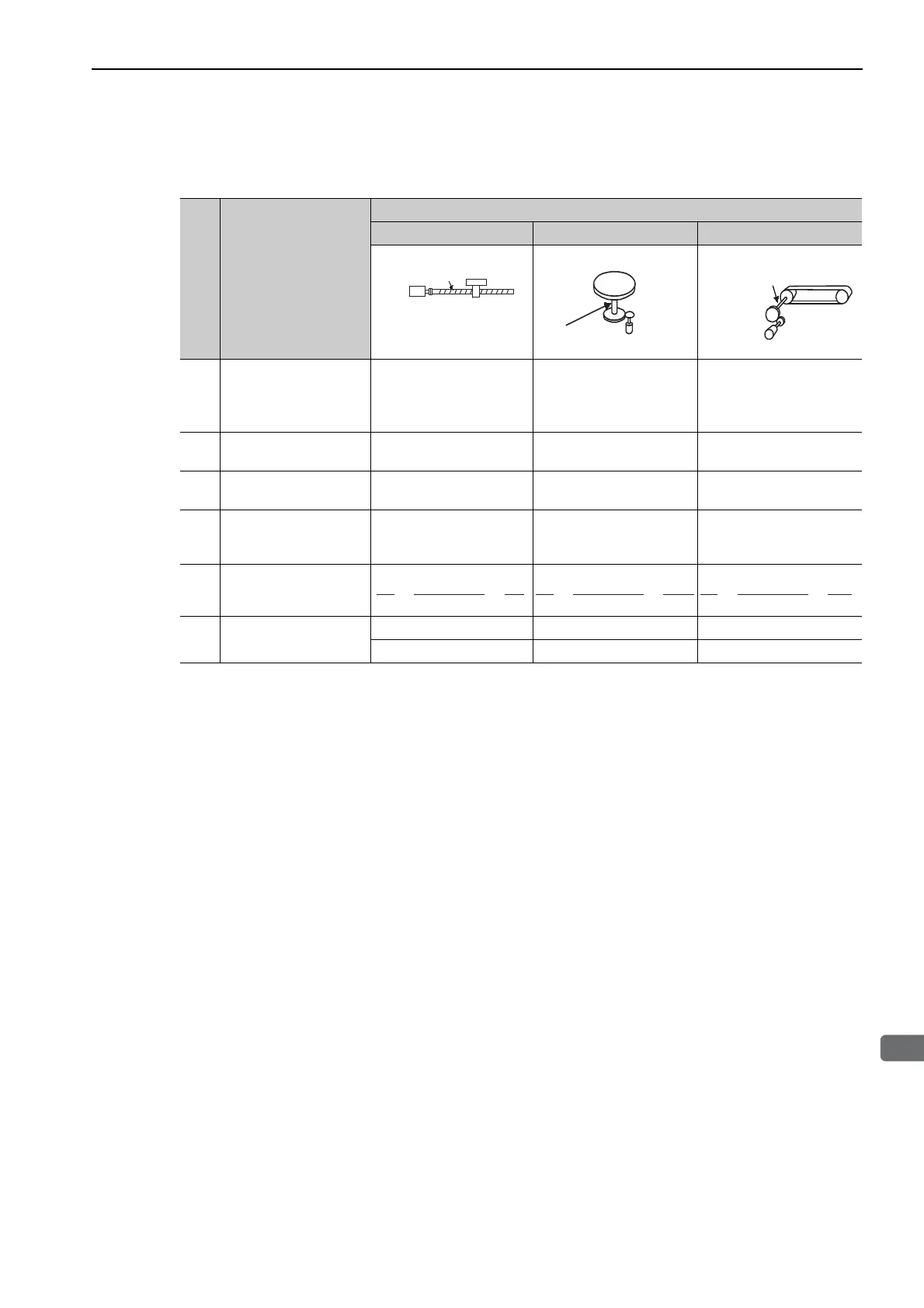

(2) Electronic Gear Ratio Setting Examples

The following examples show electronic gear ratio settings for different load configurations.

Step Operation

Load Configuration

Ball Screw Disc Table Belt and Pulley

1

Check machine specifi-

cations.

• Ball screw pitch: 6 mm

• Gear ratio: 1/1

Rotation angle per revolu-

tion: 360°

Gear ratio: 1/100

Pulley diameter: 100 mm

(pulley circumference: 314

mm)

• Gear ratio: 1/50

2

Check the encoder reso-

lution.

131072 (17-bit) 131072 (17-bit) 131072 (17-bit)

3

Determine the reference

unit used.

Reference unit: 0.001 mm

(1 μm)

Reference unit: 0.01°

Reference unit: 0.005 mm

(5 μm)

4

Calculate the travel dis-

tance per load shaft revo-

lution. (Reference unit)

6 mm/0.001 mm=6000 360°/0.01°=36000 314 mm/0.005 mm=62800

5

Calculate the electronic

gear ratio.

6 Set parameters.

PnA42: 131072 PnA42: 13107200 PnA42: 6553600

PnA44: 6000 PnA44: 36000 PnA44: 62800

Ball screw

pitch: 6 mm

17-bit encoder

Load shaft

Reference unit: 0.001 mm

17-bit encoder

Load shaft

Reference unit: 0.01

Gear ratio:

1/100

Load shaft

Gear ratio

1/50

Reference unit: 0.005 mm

Pulley diameter:

100 mm

17-bit encoder

Loading...

Loading...