11 Appendix

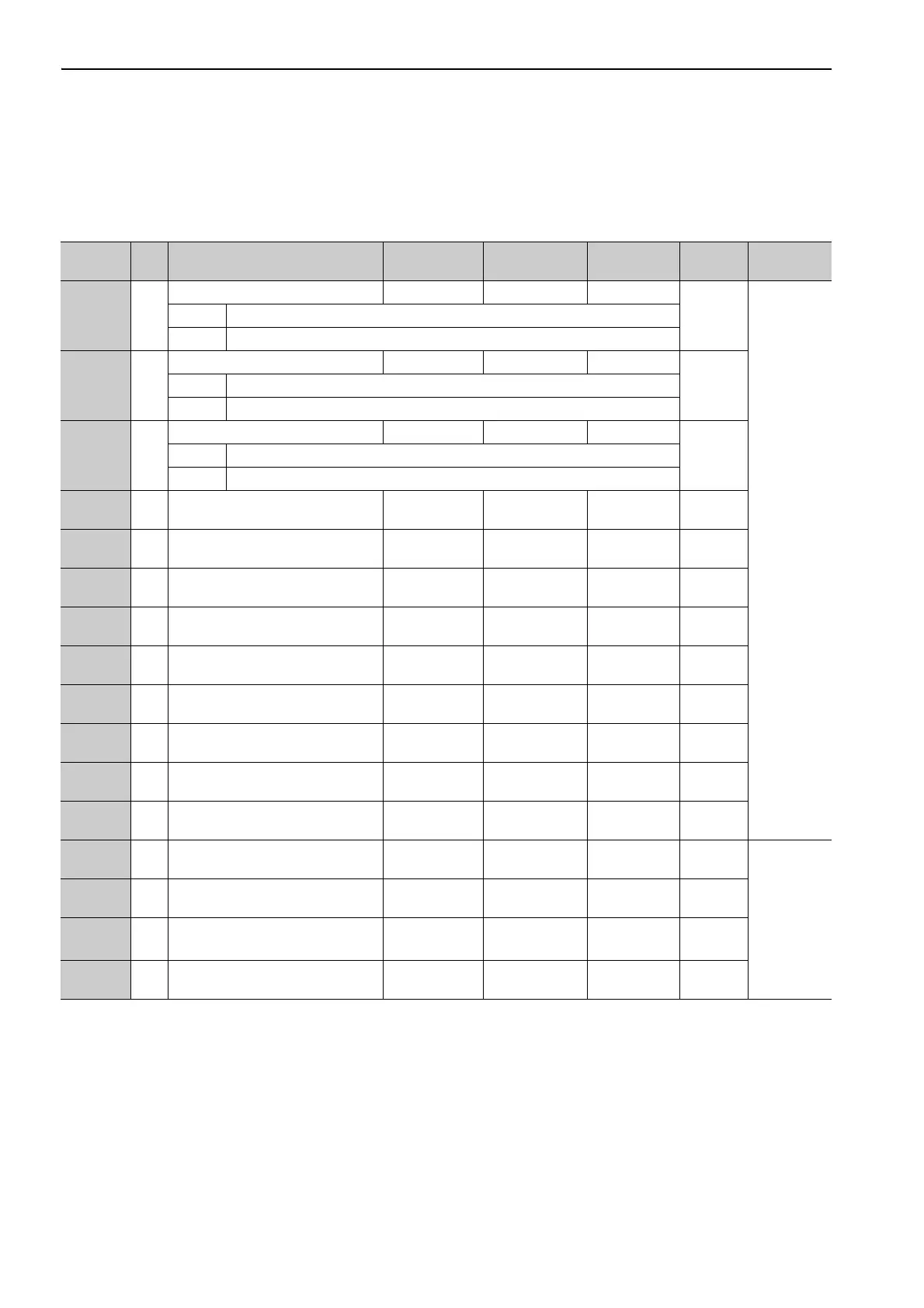

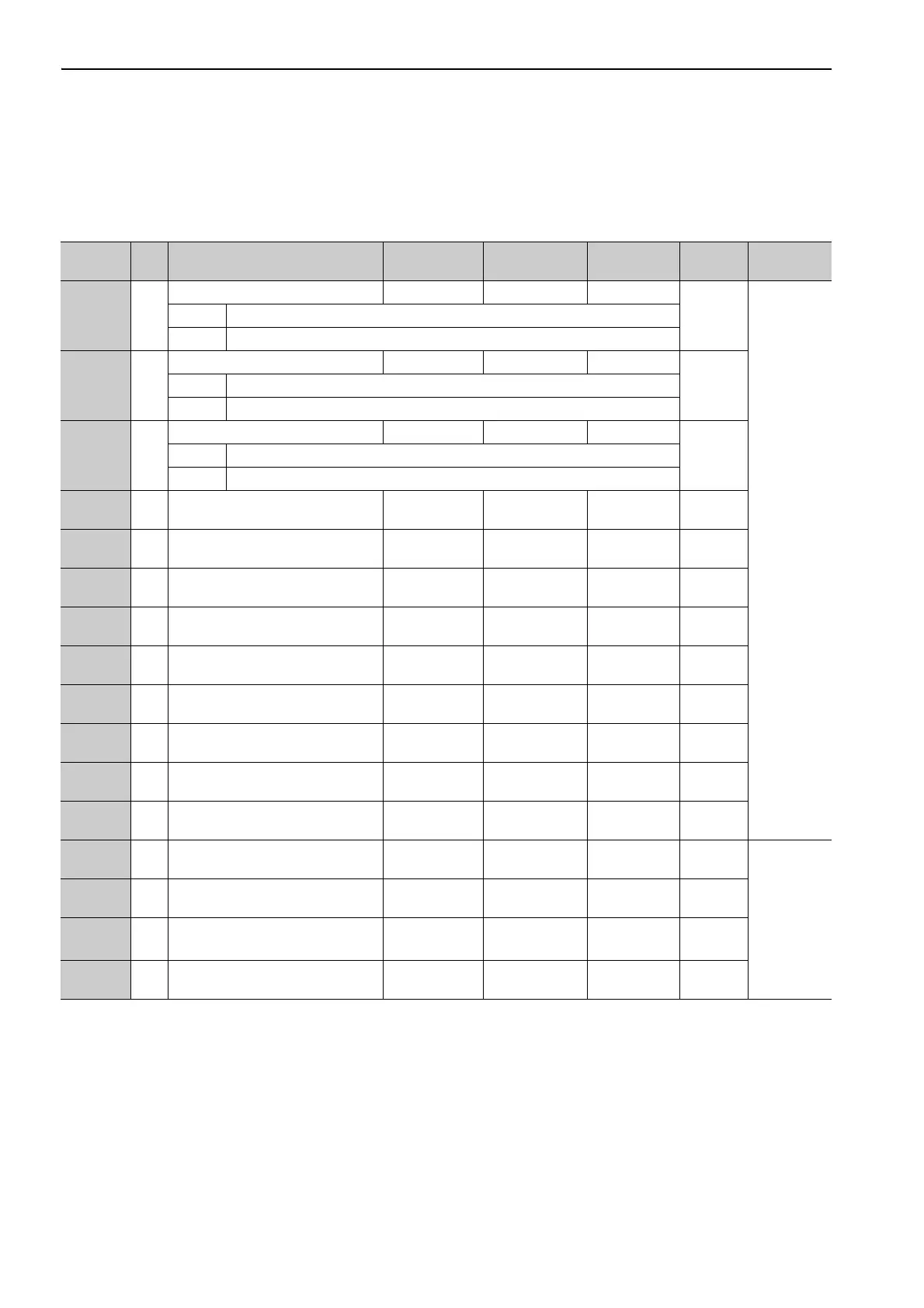

11.2.2 MECHATROLINK-III Common Parameters

11-20

11.2.2 MECHATROLINK-III Common Parameters

The following list shows the common parameters used by all devices for MECHATROLINK-III. These com-

mon parameters are used to make settings from the host controller via MECHATROLINK communications.

Do not change settings with the SigmaWin+ or any other device.

Parameter

No.

Size Name Setting Range

Units

[Resolution]

Factory

Setting

When

Enabled

Classifica-

tion

01

PnA02

4

Encoder Type (read only) 0 and 1 – –

–

Device

Information

Related

Parameters

0000H Absolute encoder

0001H Incremental encoder

02

PnA04

4

Motor Type (read only) 0 and 1 – –

–0000H Rotational servomotor

0001H Linear servomotor

03

PnA06

4

Reserved (Do not use.) – – –

–0000H Semi-closed

0001H Fully-closed

04

PnA08

4 Rated Speed (read only)

0 to

FFFFFFFFH

min

-1

––

05

PnA0A

4 Maximum Output Speed (read only)

0 to

FFFFFFFFH

min

-1

––

06

PnA0C

4 Speed Multiplier (read only) – – – –

07

PnA0E

4 Rated Torque (read only)

0 to

FFFFFFFFH

Nm––

08

PnA10

4

Maximum Output Torque (read

only)

0 to

FFFFFFFFH

Nm––

09

PnA12

4 Torque Multiplier (read only) – – – –

0A

PnA14

4 Resolution (read only)

0 to

FFFFFFFFH

pulse/rev – –

0B

PnA16

4Scale Pitch – – – –

0C

PnA18

4 Pulses per Scale Pitch – – – –

21

PnA42

4 Electronic Gear Ratio (Numerator)

1 to

1073741824

–1

After

restart

Machine

Specification

Related

Parameters

22

PnA44

4

Electronic Gear Ratio (Denomina-

tor)

1 to

1073741824

–1

After

restart

23

PnA46

4 Absolute Encoder Origin Offset

–1073741823

to 1073741823

1 reference unit 0

Immedi-

ately

*1

24

PnA48

4 Multiturn Limit Setting 0 to 65535 Rev 65535

After

restart

∗1. Available after the SENS_ON command is input.

Note: When using parameters that are enabled after restarting the SERVOPACK, a CONFIG command must be input or

the power must be turned OFF and then ON again.

Loading...

Loading...