2.2 Selecting Servomotors

2-5

2.2.2 Selection Calculations

This section describes how to make the calculations and select a servomotor for the following machine speci-

fications.

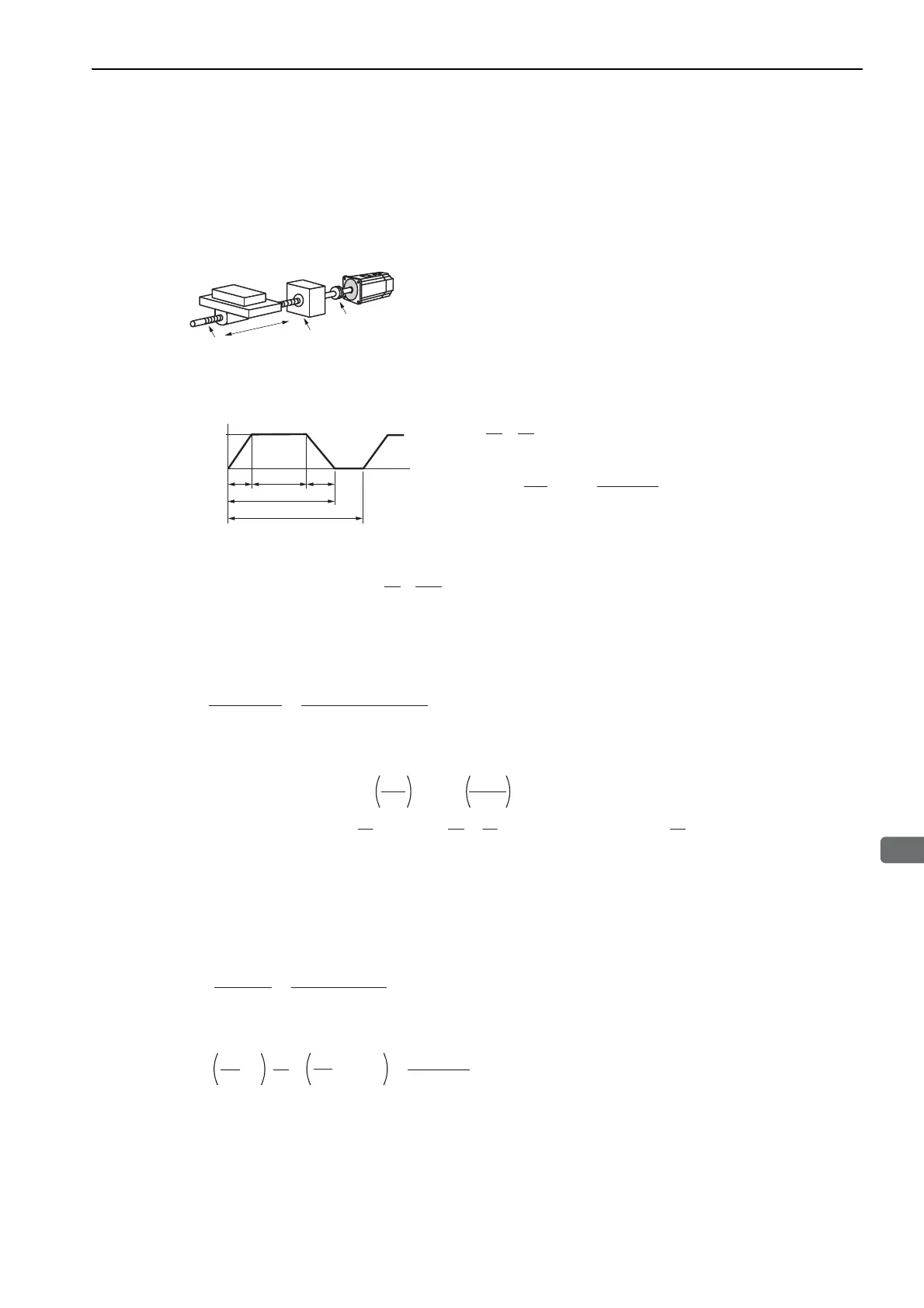

(1) Speed Diagram

(2) Rotation Speed

(3) Load Torque

(4) Load Moment of Inertia

(5) Load Moving Power

(6) Load Acceleration Power

• Load speed:

υ

L

= 15 m/min

• Linear motion section mass:

m

= 250 kg

• Ball screw length: l

B

= 1.0 m

• Ball screw diameter: d

B

= 0.02 m

• Ball screw lead: P

B

= 0.01 m

• Ball screw material density

:

ρ

= 7.87 × 10

3

kg/m

3

• Gear ratio : 1/2 (R = 2)

• Gear + coupling moment of inertia:

J

G

= 0.40 × 10

-4

kgm

2

• Feeding times: n = 40 times/min

• Feeding distance: l = 0.275 m

• Feeding time: tm = 1.2 s max.

• Friction coefficient:

μ

= 0.2

• Mechanical efficiency:

η

= 0.9 (90%)

Servomotor

Coupling

Ball screw

Gear

Linear motion

Mechanical Specifications

L

υ

tcta td

(

m/min

)

Speed

Time (s)

tm

t

L

15

υ

t

===

1

.

5

㧔

s

㧕

where ta = td

ta

=

tm

−=

1

.

2

− =

1

.

2

−

1

.

1

=

0

.

1

㧔

s

㧕

tc

=

1

.

2

−

0

.

1

×

2

=

1

.

0

㧔

s

㧕

60

n

60

40

60

×

0

.

275

15

60

ℓ

L

υ

Load axis rotation speed

nL

== =

1500

㧔

min

-1

㧕

PB

15

0

.

01

L

υ

Motor shaft rotation speed Gear ratio 1/R = 1/2 (R=2)

Therefore,

nM

=

nL

R

=

1500

×

2

=

3000

㧔

min

-1

㧕

TL

=

==

0

.

43

(

N

・

m

)

2

R

・

9

.

8

・

m

・

PB

2

2

0

.

9

9

.

8

0

.

2

250

0

.

01

μ

η

Linear motion section

JL1

=

m

=

250

× =

1

.

58

×

10

-4

㧔

kg

㨯

m

2

㧕

2

2

π

R

P

B

2

2

π

×

2

0

.

01

Ball screw

JB

=

ℓB

dB

4

= ×

7

.

87

×

10

3

×

1

.

0

×

㧔

0

.

02

㧕

4

=

0

.

31

×

10

-4

㧔

kg

㨯

m

2

㧕

R

2

1

32

π

2

2

1

32

π

ρ

Coupling

JG

=

0

.

40

×

10

-4

㧔

kg

m

2

㧕

Load moment of

inertia at motor shaft

JL

=

JL1

+

JB

+

JG

=

㧔

1

.

58

+

0

.

31

+

0

.

40

㧕

×

10

-4

=

2

.

29

×

10

-4

㧔

kg

m

2

㧕

PO

=

= =

135

(

W

)

60

2

nM

・

TL

60

2

3000

0

.

43

Pa

=

= =

226

(

W

)

nM

2

60

2

ta

J

L

3000

2

60

2

0

.

1

2

.

29

10

-4

Loading...

Loading...