<14. EXPLOSION PROTECTED TYPE INSTRUMENT>

14-2

IM 01E30D01-01EN

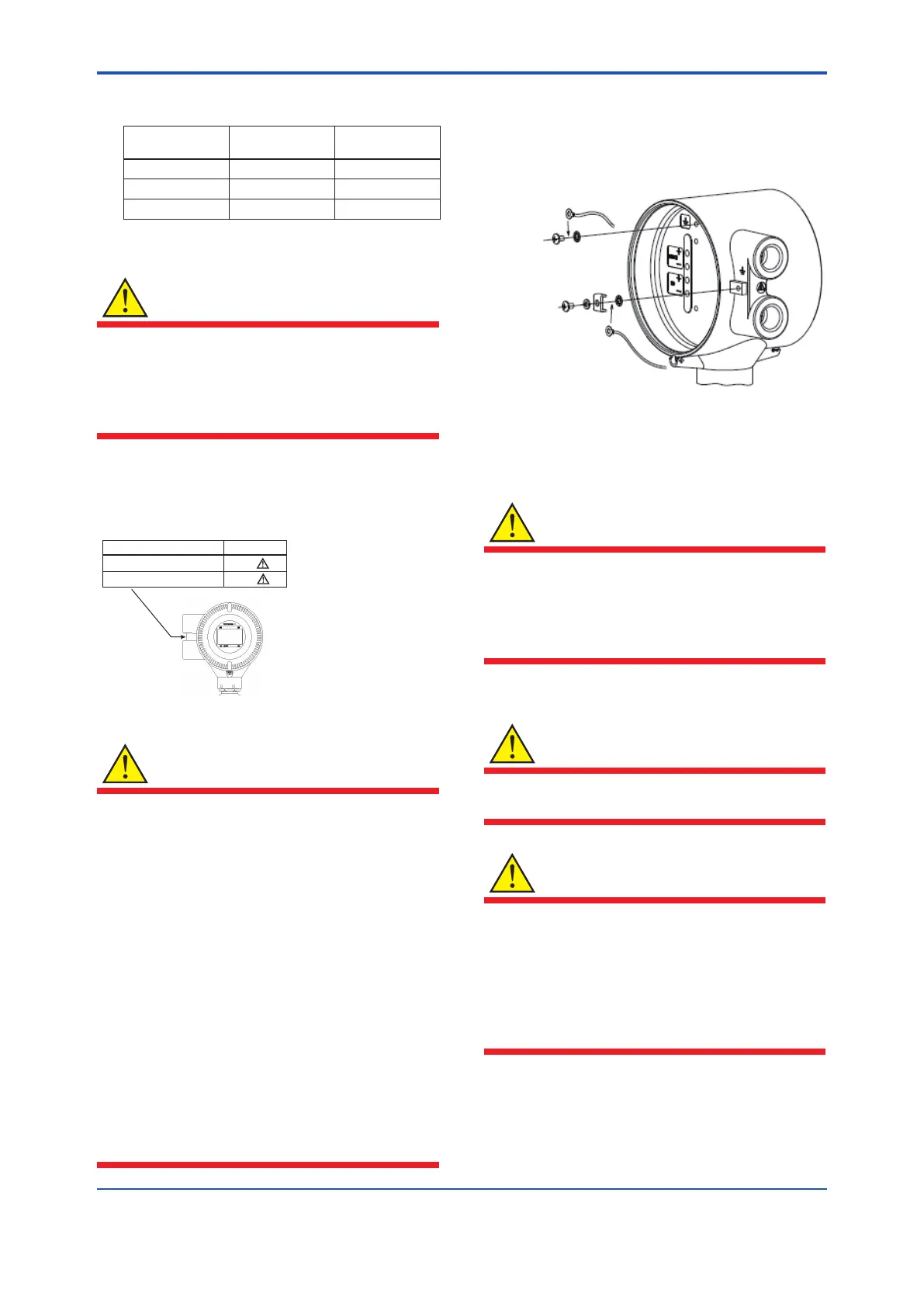

Enclosure: IP66/IP67

Process Temperature:

Maximum Surface

Temperature

Maximum Process

Temperature

Minimum Process

Temperature

T90°C (+194°F) +70°C (+158°F) –30°C (–22°F)

T110°C (+230°F) +85°C (+185°F) –30°C (–22°F)

T130°C (+266°F) +130°C (+266°F) –30°C (–22°F)

Ambient Temp.: –30°C to +55°C

(–22°F to +131°F)

WARNING

IftheAXRismountedinanareawheretheuseof

EPL Db equipment is required, it shall be installed

in such a way that the risk from electrostatic

discharges and propagating brush discharges

causedbyrapidowofdustisavoided.

(2) Electrical Connection

The type of electrical connection is stamped near

the electrical connection port according to the

following codes.

ISO M20x1.5 female M

ANSI 1/2NPT female N

Screw Size Marking

(3) Installation

WARNING

• Groundingresistanceof100Ωorlessis

necessary.

When optional code A is selected, grounding

resistanceof10Ωorlessshallberequired.

•

All wiring shall comply with EN 60079-14, and local

installation requirements and local electrical code.

• Inhazardouslocations,thecableentry

devicesshallbeofacertiedATEX

ameprooftype,suitablefortheconditionsof

use and correctly installed.

•

Unused apertures shall be closed with suitable

ameproofcertiedblankingelements.(The

plugattachedisameproofcertied.)

• Inordertopreventthegroundingring

conductor from loosening, the conductor

must be secured to the terminal, tightening

the screw with appropriate torque. Care must

be taken not to twist the conductor.

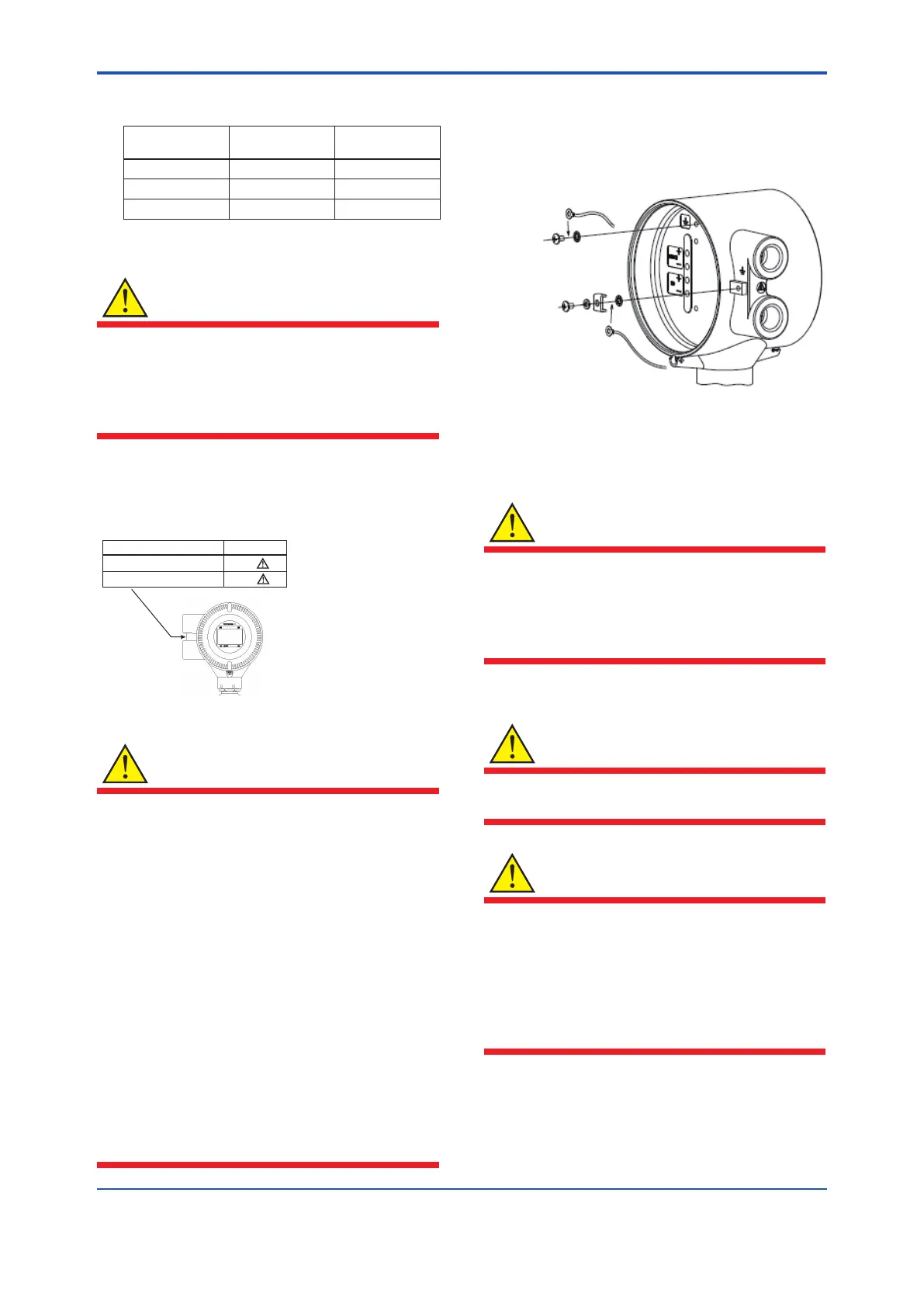

The grounding terminals are located on the inside

and outside of the terminal area.

Connect the cable to grounding terminal in

accordance with wiring procedure 1) or 2).

F1402.ai

1) Internal grounding

terminal

External grounding

Figure 14.1 Wiring Procedure for Grounding

Terminals

(4) Operation

WARNING

• Afterde-energizing,delay5minutesbefore

opening.

• Takecarenottogeneratemechanical

spark when access to the instrument and

peripheral devices in hazardous locations.

(5) Maintenance and Repair

WARNING

Only personnel authorized by Yokogawa Electric

Corporation can repair the equipment.

WARNING

• Electrostaticchargemaycauseanexplosion

hazard. Avoid any actions that cause the

generation of electrostatic charge, such as

rubbing with a dry cloth on coating face of

product.

• Modicationoftheameproofjointisnot

allowed.

Loading...

Loading...