ENGINE INSTALLATION

NOTES

After the engine is installed in the frame, review this checklist

and perform all steps that apply.

General Items

◎ Install previously removed components using new gaskets,

seals, and fasteners where applicable.

◎ Perform regular checks on fluid levels,

inspection checklist (refer to Chapter 2).

CVT System

◎ Clean clutch sheaves thoroughly and inspect inlet and

outlet ducts for proper routing and sealing.

◎ Inspect clutch rollers, shoes and springs before reassembly.

Transmission

◎ Inspect transmission operation and adjust linkage if

necessary.

Exhaust

◎ Replace exhaust gaskets. Seal connections if desired with

high temp sealant.

◎ After running the engine, verify all bolted exhaust

connections are tight and in good condition.

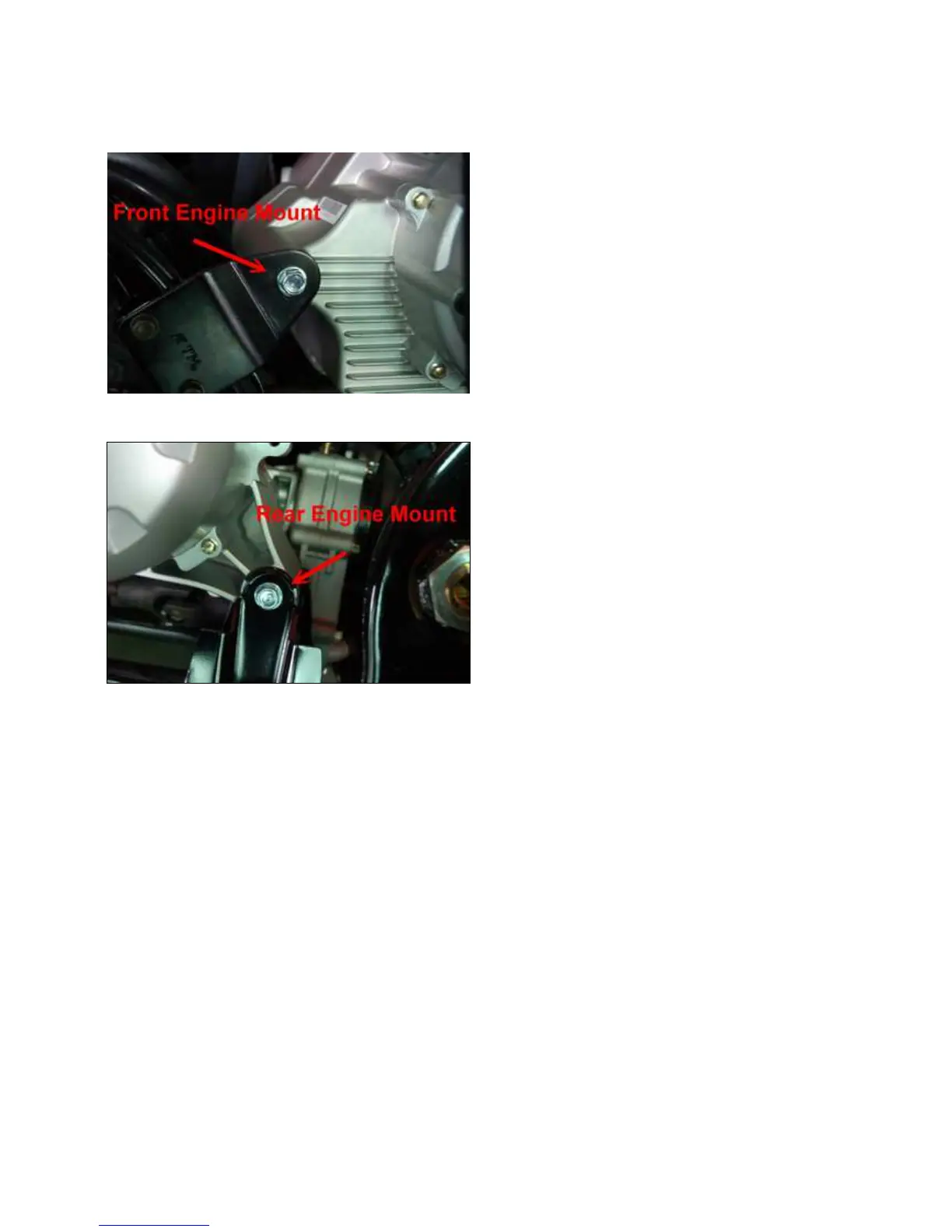

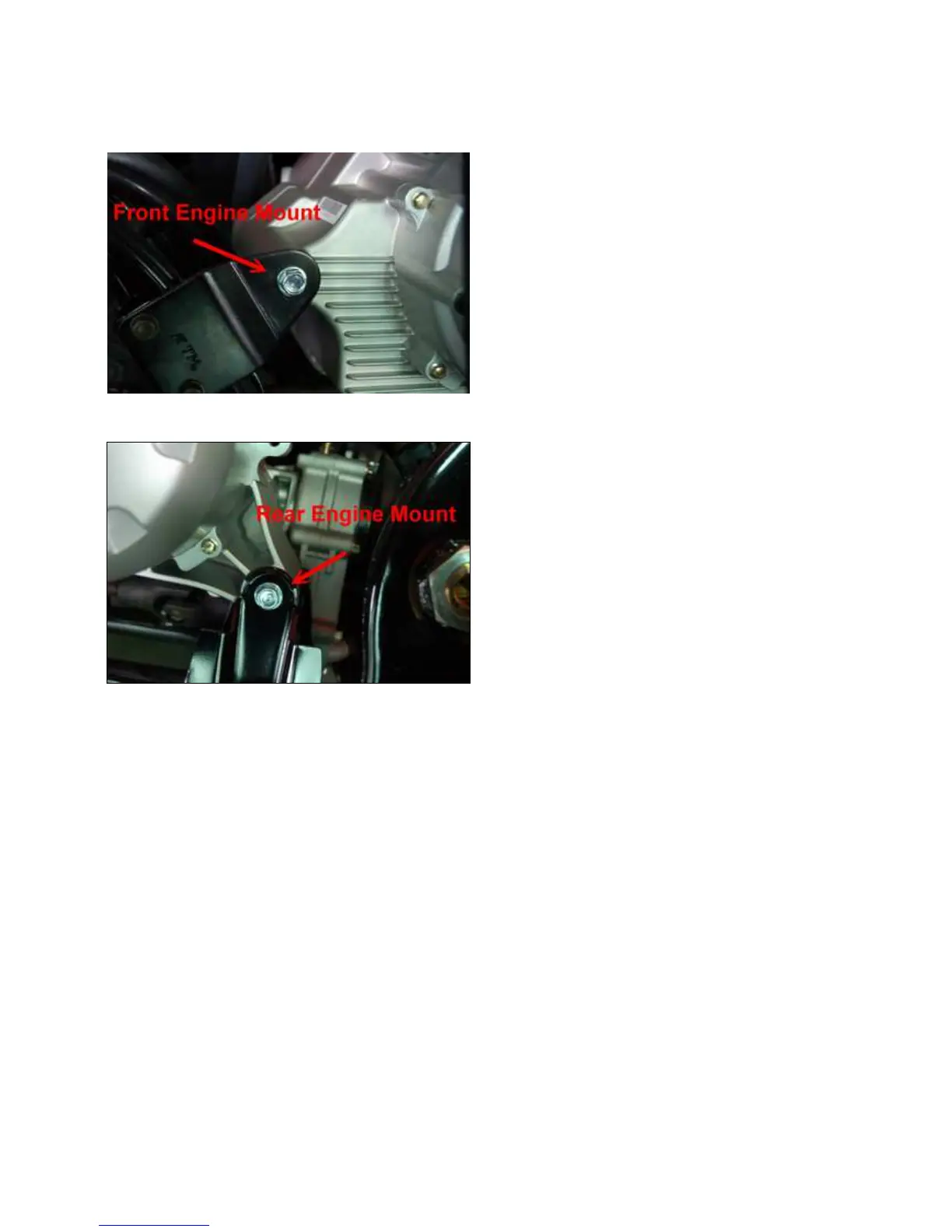

Engine Mount Torque

◎ Front Mount – 80Nm

◎ Rear Mounts –80Nm

Engine Break In Period

4 Cycle Engine Break-In Period is defined as the first

10 hours of engine operation or 2 full tanks of fuel.

◎ Use only All Season Synthetic Oil, or API certified

“SH” oil.

◎ Use fuel with a minimum octane of 87 (R+M)/2 method.

◎ Change break-in oil and filter at 20 hours or 100 miles,

whichever comes first.

Radiator System

◎ Fill 50% coolant water (50% Ethylene Glycol and 50%

water) to radiator, not only water.

ENGINE LUBRICATION

Oil Type 0--40W Synthetic oil

Capacity Approximately 1800 cc

Drain Plug/ Screen Fitting 20 Nm

Oil Pressure Specification: Continuous oil-flow out of stator

housing plug hole at Idle RPM. 0W--40 Synthetic.

Loading...

Loading...