ENGINE

4-26

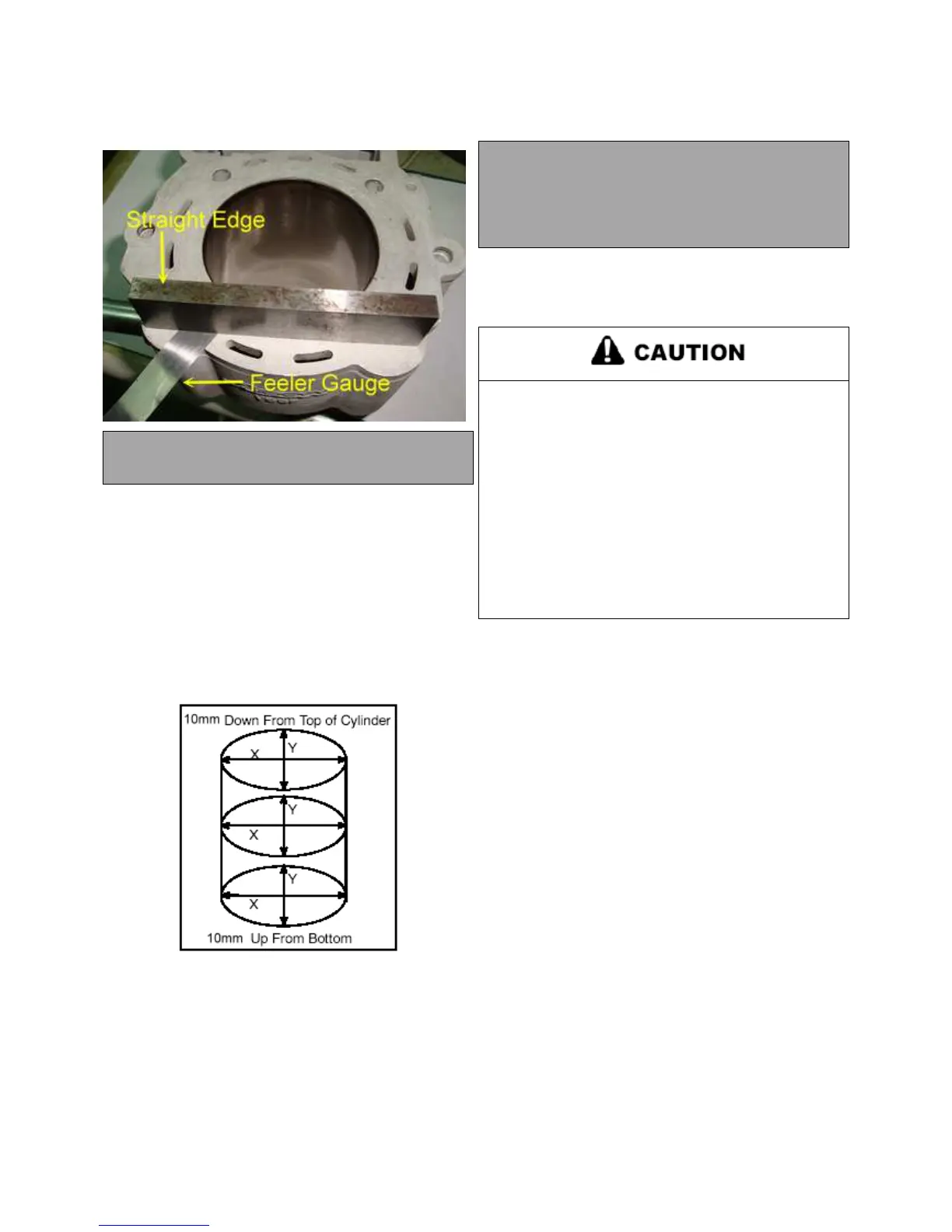

CYLINDER WARP:

0.05 mm MAX

3. Inspect cylinder for wear, scratches, or damage.

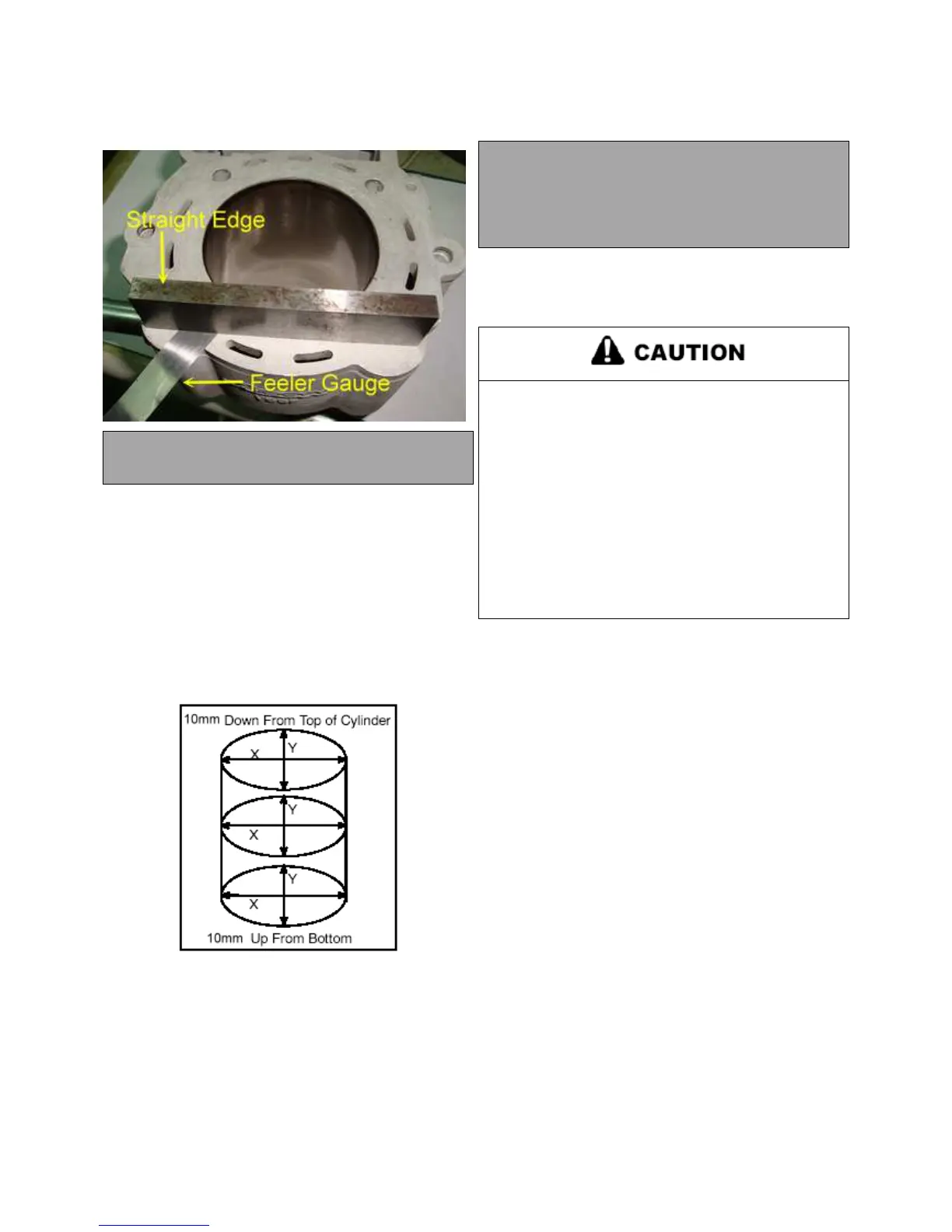

4. Inspect cylinder for taper and out of round with a

telescoping gauge or a dial bore gauge. Measure in two

different directions, front to back and side to side, on three

different levels (10mmdown from top, in the middle, and

10mmup from bottom).

5. Record measurements. If cylinder is tapered or

beyond specification, the cylinder

replaced.

CYLINDER TAPER

Limit: 0.05mm Max.

CYLINDER OUT OF ROUND

Limit: 0.05mm Max.

CYLINDER HONE SELECTION/HONING

PROCEDURE

A hone, which will straighten as well as remove

material from the cylinder, is very important. Using a

common spring loaded glaze breaker for honing is

not advised. Polaris recommends using a rigid hone

or arbor-honing machine. Cylinders may be wet or

dry honed depending upon the hone manufacturer’s

recommendations. Wet honing removes more

material faster and leaves a more distinct pattern in

the bore.

HONING TO DEGLAZE

A finished cylinder should have a crosshatch pattern to ensure

piston ring seating and to aid in the retention of the fuel/oil

mixture during initial break in. Hone cylinder according to

hone manufacturer’s instructions, or these guidelines:

◎ Use a motor speed of approximately 300-

hone in and out of the cylinder rapidly until cutting tension

decreases. Remember to keep the hone drive shaft centered (or

cylinder centered on arbor) and to bring the stones

approximately 1.3 cm above and below the bore at the end of

each stroke.

◎ Release the hone at regular intervals

determine if it has been sufficiently deglazed, and to check for

correct cross--hatch.

NOTE: Do not allow cylinder to heat up during

honing.

Loading...

Loading...