ENGINE

4-46

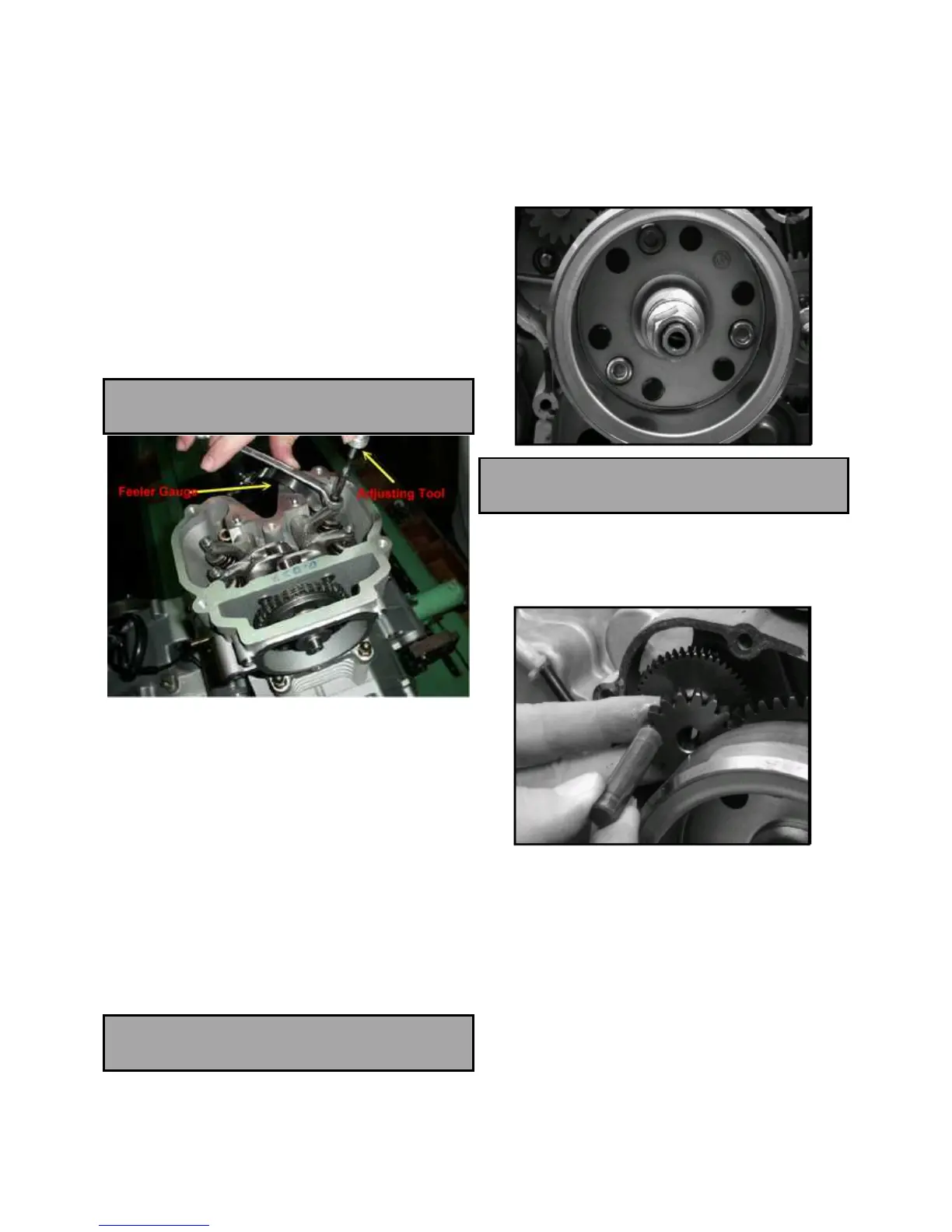

INTAKE VALVE CLEARANCE ADJUSTMENT

1. Verify cam lobes are pointed down.

2. Insert a 0.1mm feeler gauge between end of intake valve

stem and adjuster screw.

3. When clearance is correct, hold adjuster screw and tighten

locknut securely.

4. Re-check the valve clearance.

5. Repeat adjustment procedure if necessary until clearance is

correct with locknut secured.

VALVE CLEARANCE

0.12 mm

EXHAUST VALVE CLEARANCE

ADJUSTMENT

1. Verify cam lobes are pointed down.

2. Insert a 0.1mm feeler gauge between end of exhaust valve

stem and adjuster screw.

3. Loosen locknut and turn adjuster screw until there is a slight

drag on feeler gauge.

4. When clearance is correct, hold adjuster screw and tighten

locknut securely.

5. Re-check the valve clearance.

6. Repeat adjustment procedure if necessary until clearance is

correct with locknut secured.

VALVE CLEARANCE

0.12 mm

FLYWHEEL INSTALLATION

1. Install flywheel key, flywheel washer, and nut.

Torque flywheel nut to specification.

FLYWHEEL NUT TORQUE:

100 Nm

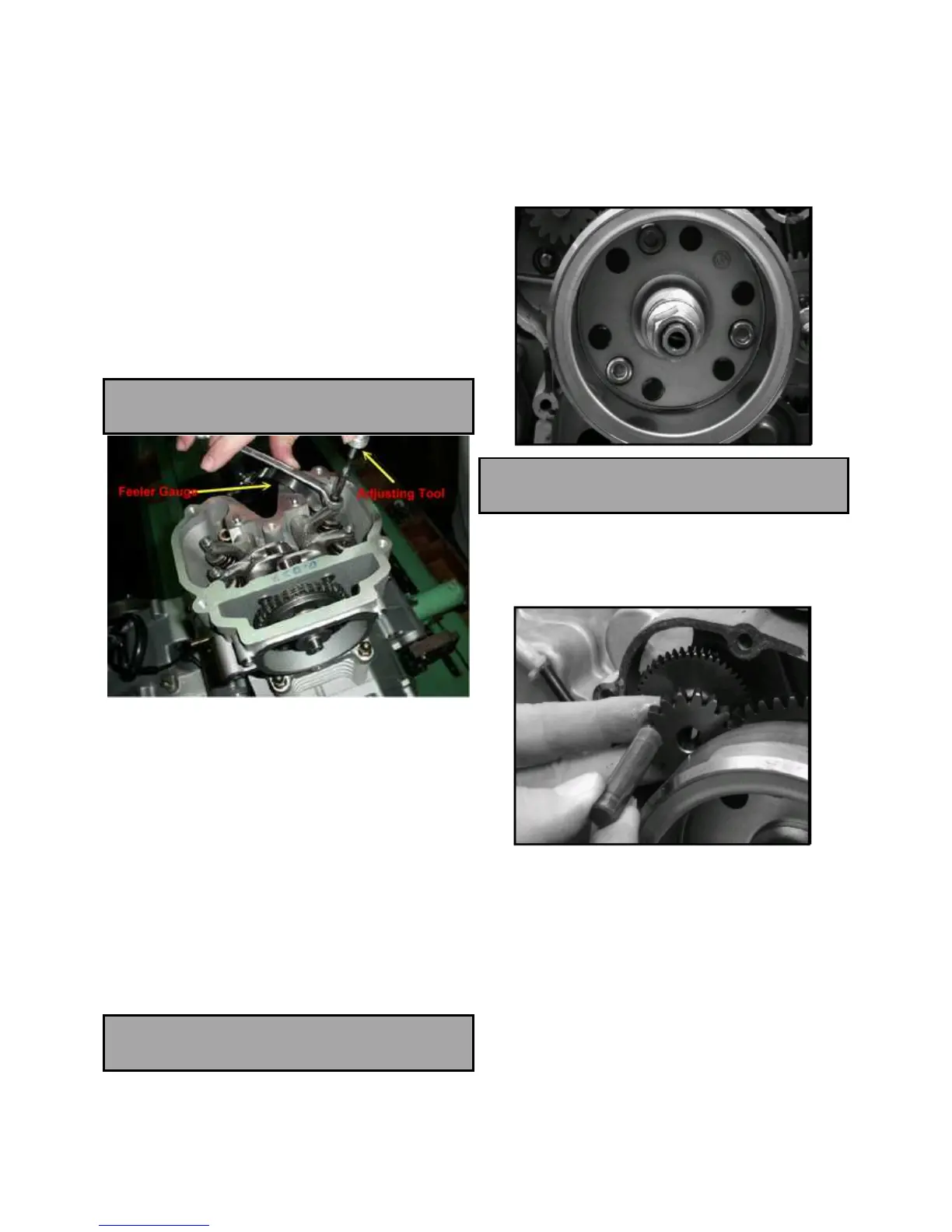

STARTER DRIVE ASSEMBLY

1. Be sure the washer is positioned on the back of the drive

gear.

2. Apply Starter Drive Grease to the drive bushings in the

cases and all moving surfaces of the starter drive gears and

install.

3. Install stator housing and torque bolts to specification.

Loading...

Loading...