How to fix loud buzzing or vibration from Brooks PreciseFlex 400 Robotics joint?

- HhickshollySep 2, 2025

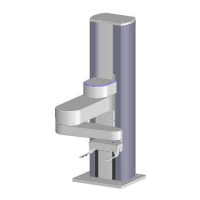

To address loud buzzing or vibration from a joint in your Brooks Robotics system, re-tension the timing belts. If the timing belt will not hold tension, replace it.