3-88 2007 Buell Lightning: Engine

HOME

INSTALLATION

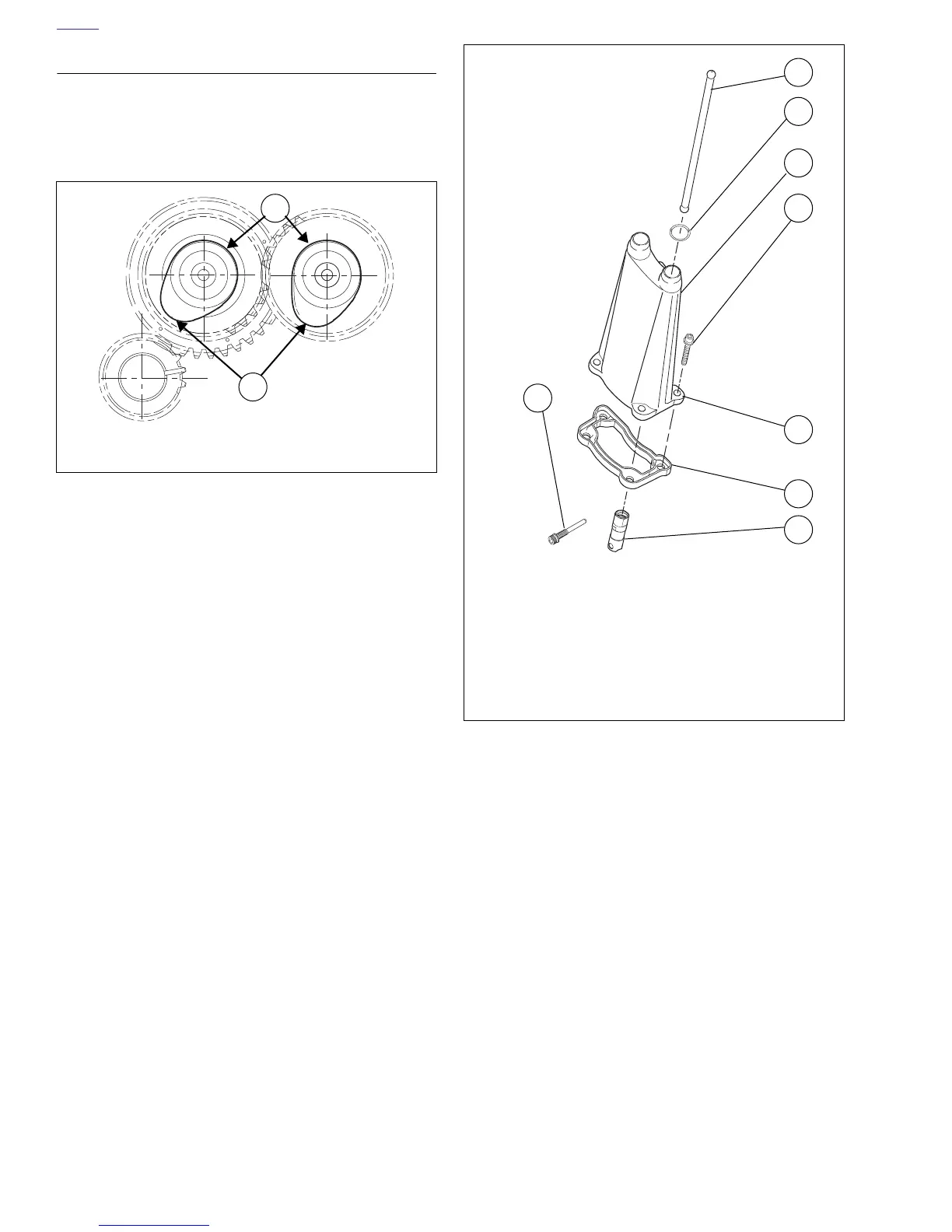

1. See Figure 3-124. Rotate engine so that both lifters from

the cylinder will be installed on the base circle of the

cam.

2. Apply a liberal amount of engine oil to each lifter assem-

bly (especially the roller needles) for smooth initial opera-

tion.

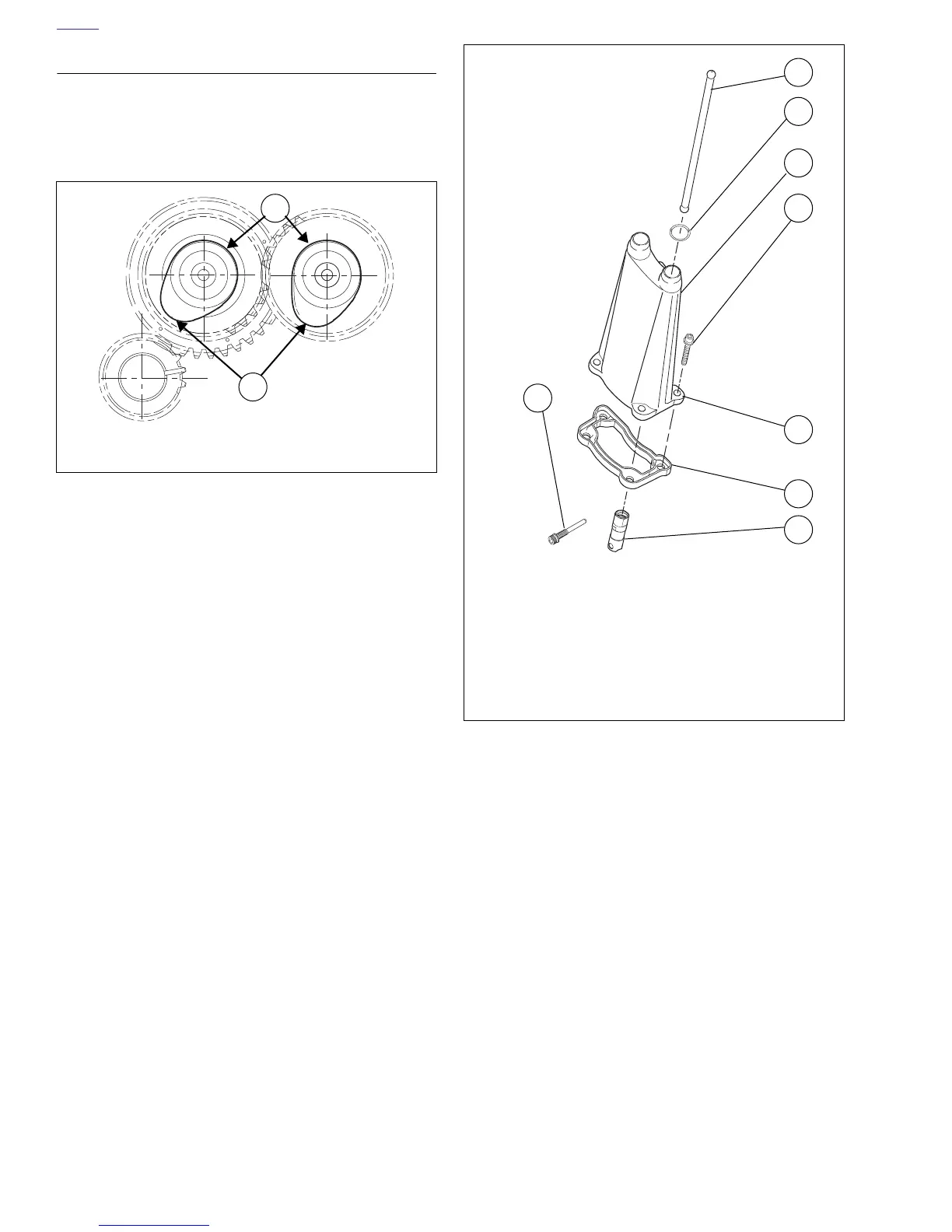

3. See Figure 3-125. Insert lifter into bore in crankcase.

Rotate lifter so that flats at upper end of lifter face the

front and rear of the engine. If the lifter is installed incor-

rectly, anti-rotation screws cannot be inserted.

4. Secure lifters in place.

a. Install anti-rotation screws with washers in the holes

in lifter block.

b. Tighten anti-rotation screws to 55-65 in-lbs (6-7

Nm).

NOTE

Before installing orings on top of pushrod cover be sure to

apply a small amount of clean engine oil to each oring.

5. See Figure 3-125. Install push rod cover.

a. Place new push rod cover gasket (6) over bottom of

push rod cover.

b. Position push rod cover onto crankcase.

c. Install screws (4) through holes in push rod cover

into tapped holes in crankcase. Tighten screws

evenly to 30-40 in-lbs (3-5 Nm).

d. Place new o-rings (2) on top of push rod cover (3).

6. Install push rods, cylinder head, lower and upper rocker

covers. See 3.6 CYLINDER HEAD.

7. Repeat process for remaining cylinder head.

Figure 3-124. Base Circle

2K

1K

b1037x3a

1

2

1. Base circle (lowest position)

2. Cam lobe (maximum lift)

Figure 3-125. Valve Lifter Service

b1048x3x

1

2

3

4

5

6

7

8

1. Push rod (exhaust)

2. O-ring

3. Push rod cover

4. Screws (4)

5. Push rod cover

6. Push rod cover gasket

7. Hydraulic lifter (tappet)

8. Anti-rotation screw

Loading...

Loading...