1-28 2007 Buell Lightning: Maintenance

HOME

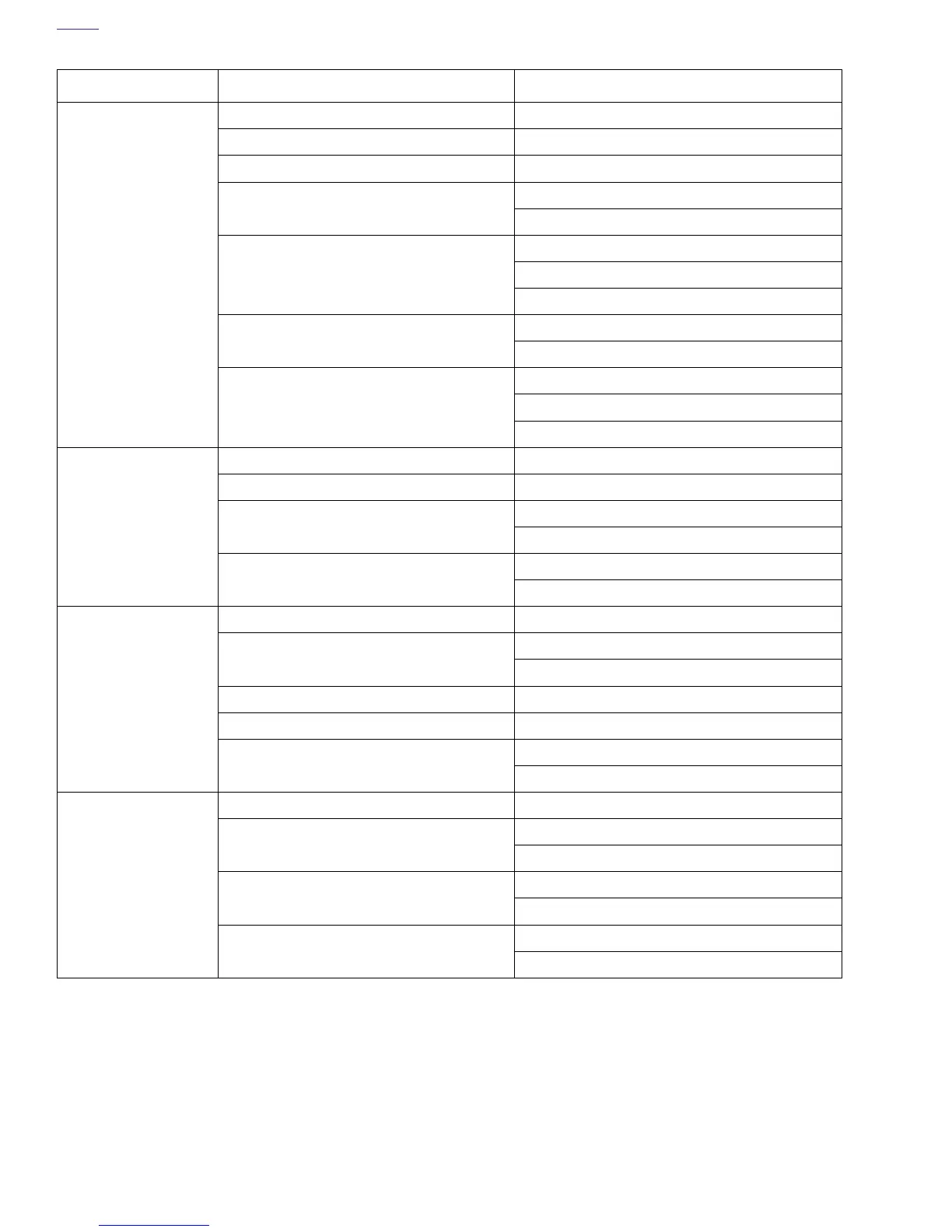

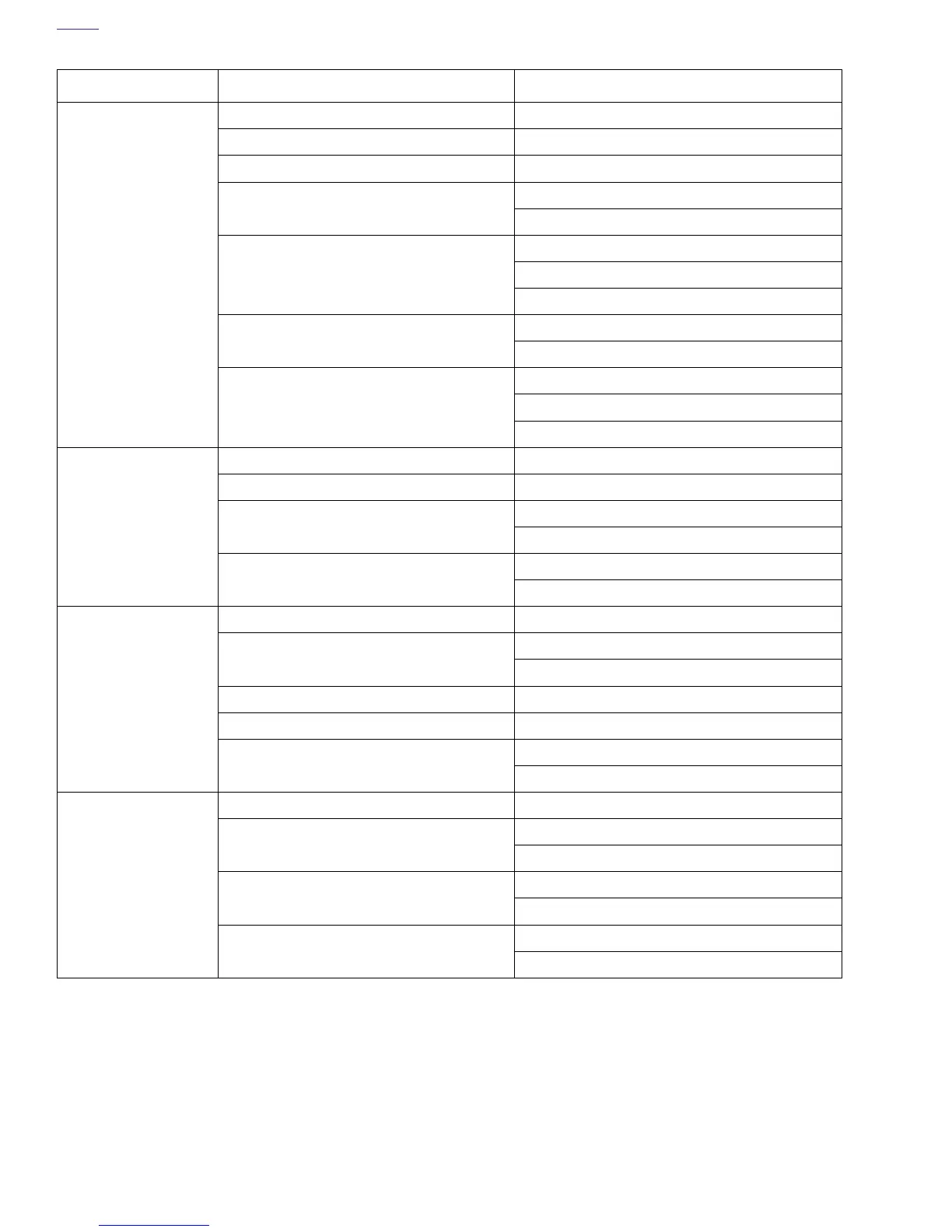

Table 1-8. Potential Limits to Belt Drive Service Life

CONDITION ROOT CAUSE REQUIRED ACTION

Excessive Edge Wear

(mistracking)

Misalignment or bent drive structure Check structure (bad bearing, bent members, etc.)

Bent or rough flange Repair flange/replace sprocket

Damage due to handling (pry on, etc.) Follow proper handling/installation procedure

Debris damage to edge of belt

Inspect/replace belt

Inspect for damaged or missing guards

Belt hitting obstruction

Check structure (bad bearing, bent members, etc.)

Inspect for loose/missing fasteners

Inspect for damaged or missing guards

Bent or loose idler bracket

Replace idler assembly

Inspect for loose/missing fasteners

Broken or loose guards

Check structure (bad bearing, bent members, etc.)

Inspect for loose/missing fasteners

Inspect for damaged or missing guards

Excessive tooth wear

Rough or damaged sprocket Inspect/replace sprocket

Worn sprocket Inspect/replace sprocket

Debris in sprocket

Clean and protect drive

Inspect for damaged or missing guards

Abrasive environment

Eliminate or control exposure

Inspect for damaged or missing guards

Apparent belt stretch

NOTE

The drive belt tension on

a new belt will loosen

after approximately 1000

mi (1600 km)

Worn sprocket Inspect/replace sprocket

Debris in sprocket

Clean and protect drive

Inspect for damaged or missing guards

Idler bearing failure Replace idler assembly

Aggressive riding/hard use Riding practice/operator choice

Exposure to oils, solvents, harsh chemicals

Eliminate or control exposure

Clean and protect drive

Cracks in back of belt

Idler/bearing binding Replace idler assembly

Exposure to oils, solvents, harsh chemicals

Eliminate or control exposure

Clean and protect drive

Cut by sharp debris (not at belt edge)

Inspect/replace sprocket

Continue to run but monitor condition frequently

Cut by sharp debris at belt edge

Inspect/replace sprocket

Inspect/replace belt

Loading...

Loading...