B-14 Appendix B: Wiring

HOME

SPLICING WIRE LEADS

NOTE

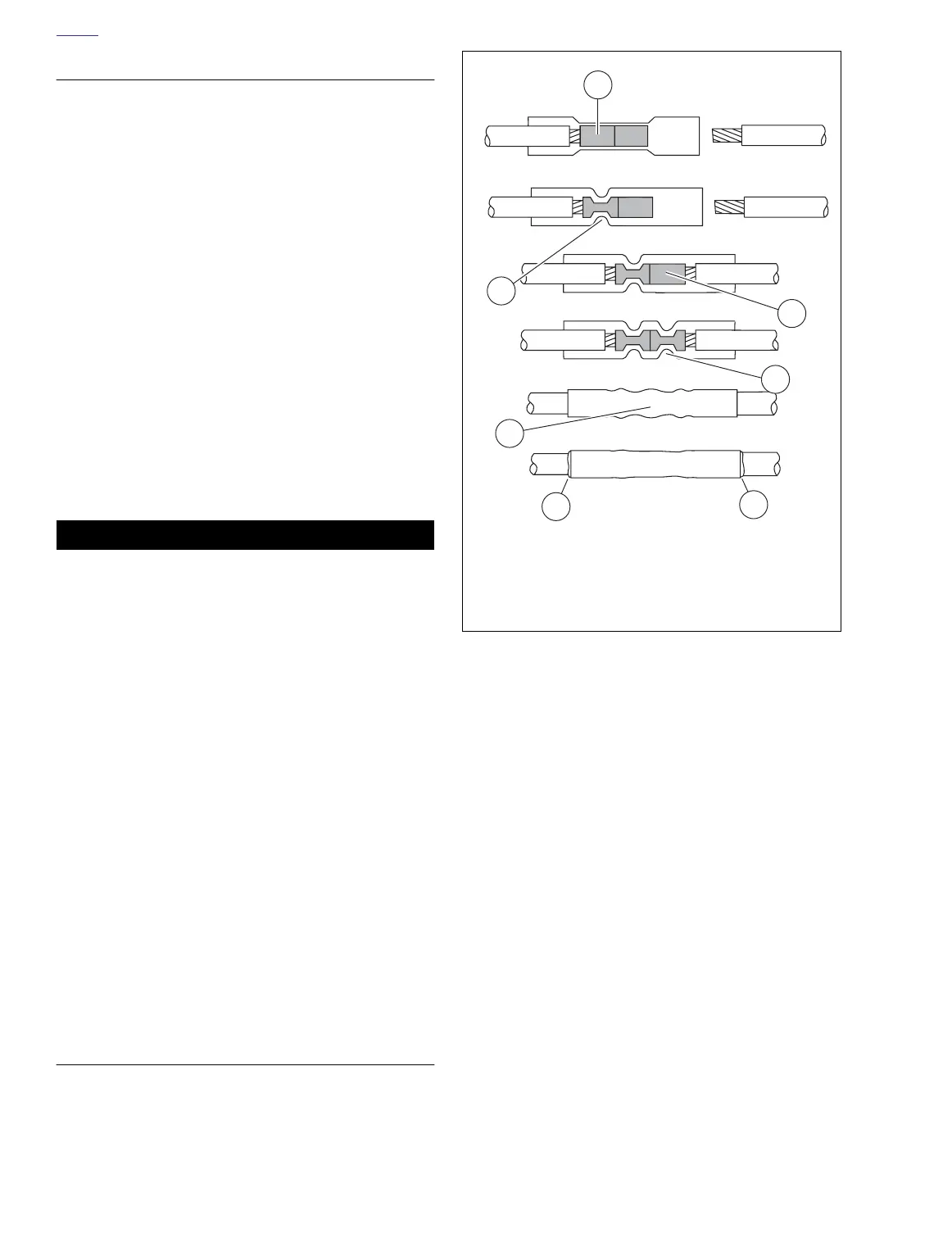

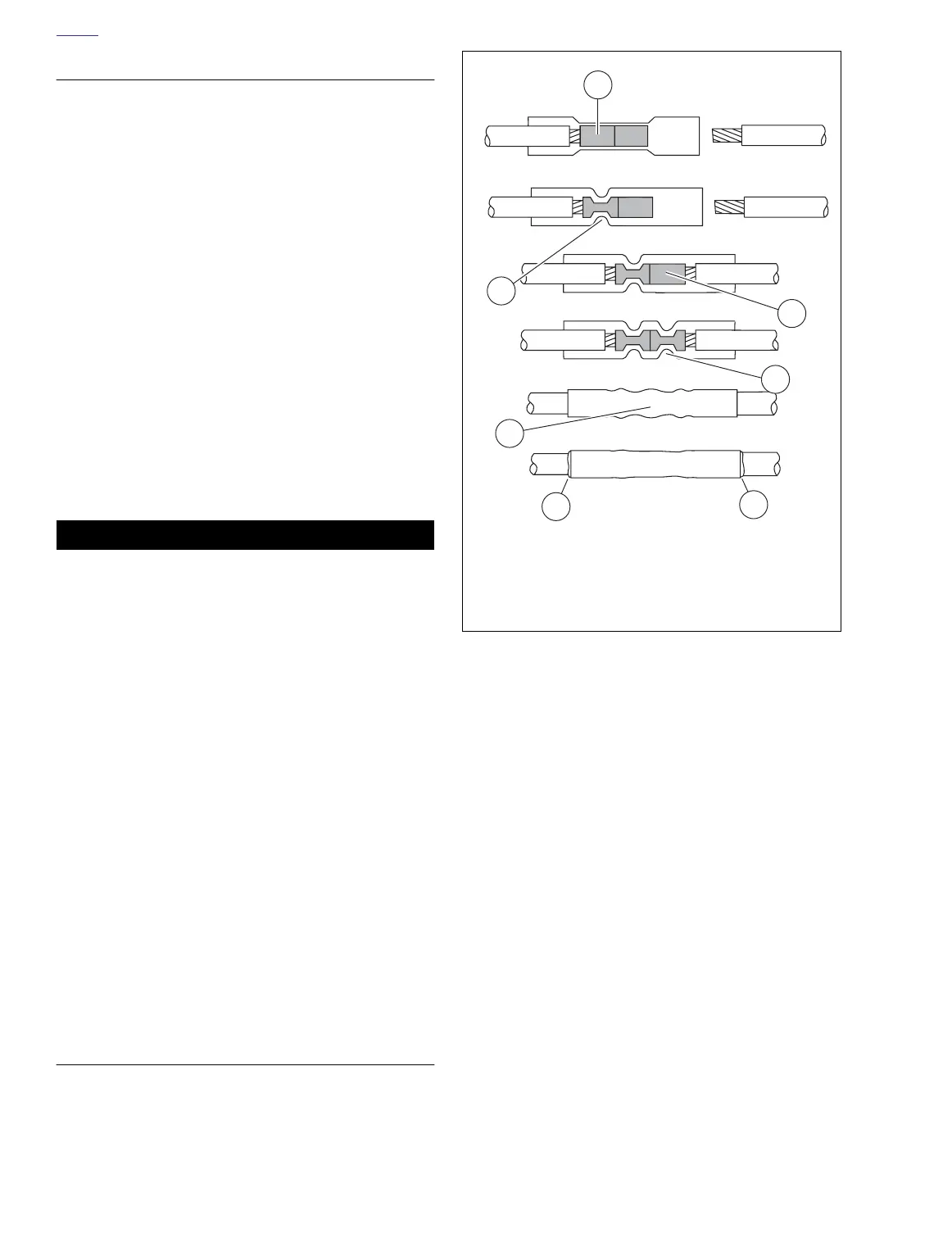

See Figure B-16.

T

he connector is crimped twice - one side

and then the other.

1. See Figure B-15. Open the Packard Crimping Tool (HD-

38125-8) ratchet by squeezing the handles closed.

2. Match the connector color to the wire gauge crimp die in

the jaws and insert one end of the sealed connector.

3. Gently squeeze the handles until the connector is held in

the jaws.

4. See Figure B-16. Feed the stripped end of a wire into the

connector until the wire stops inside the metal insert (1).

5. Squeeze the handles tightly closed to crimp the lead in

the insert (2). The tool automatically opens when the

crimping is complete.

6. Slide the connector to the other half of the metal insert.

Insert the stripped wire lead (1) until it stops, and crimp

the lead in the insert (2).

11WARNING1WARNING

Be sure to follow manufacturer's instructions when

using the Ultra-Torch UT-100 or any other radiant heating

device. Failure to follow manufacturer's instructions can

cause a fire, which could result in death or serious injury.

(00335a)

●

Avoid directing heat toward any fuel system compo-

nent. Extreme heat can cause fuel ignition/explosion

resulting in death or serious injury.

●

Avoid directing heat toward any electrical system

component other than the connectors on which heat

shrink work is being performed.

●

Always keep hands away from tool tip area and heat

shrink attachment.

7. Use an Ultra-Torch (HD-39969), or a Heat Gun (HD-

25070) with a Heat Shield Attachment (HD-41183), to

heat the connector from the center of the crimp (3) out to

each end.

NOTE

It is acceptable for the splice to rest against the heat shrink

tool attachment.

INSPECT SEAL

See Figure B-16. Allow the splice to cool and inspect the

seal. The insulation should appear smooth and cylindrical.

Melted sealant will have extruded out the ends (4) of the insu-

lation.

Figure B-16. Sealed Splice Connector

1

1

4

2

2

4

3

f2525x1x

1. Wire lead in metal insert

2. Crimped metal insert

3. Center of crimp

4. Melted sealant

Loading...

Loading...