Appendix B: Wiring B-13

HOME

SEALED SPLICE B.3

GENERAL

Splice connectors and several OE ring terminal connectors

use heat shrink covering to seal the connection.

PREPARE THE WIRE LEADS

NOTE

If adjacent wires are to be spliced, stagger the splices so that

the sealed splice connectors will not touch each other but are

located at different positions along the length of the wires.

1. Identify (use a shop gauge) the gauge of the wire.

2. Match the wire gauge to a sealed splice connector by

color and part number. Refer to Table B-5.

3. Using a wire stripper, cut and strip a length of insulation

off the wire ends. Refer to Table B-5. for the strip length.

NOTE

If any copper wire strands are cut off of the wire core, trim the

end and strip the wire again in a larger gauge stripper.

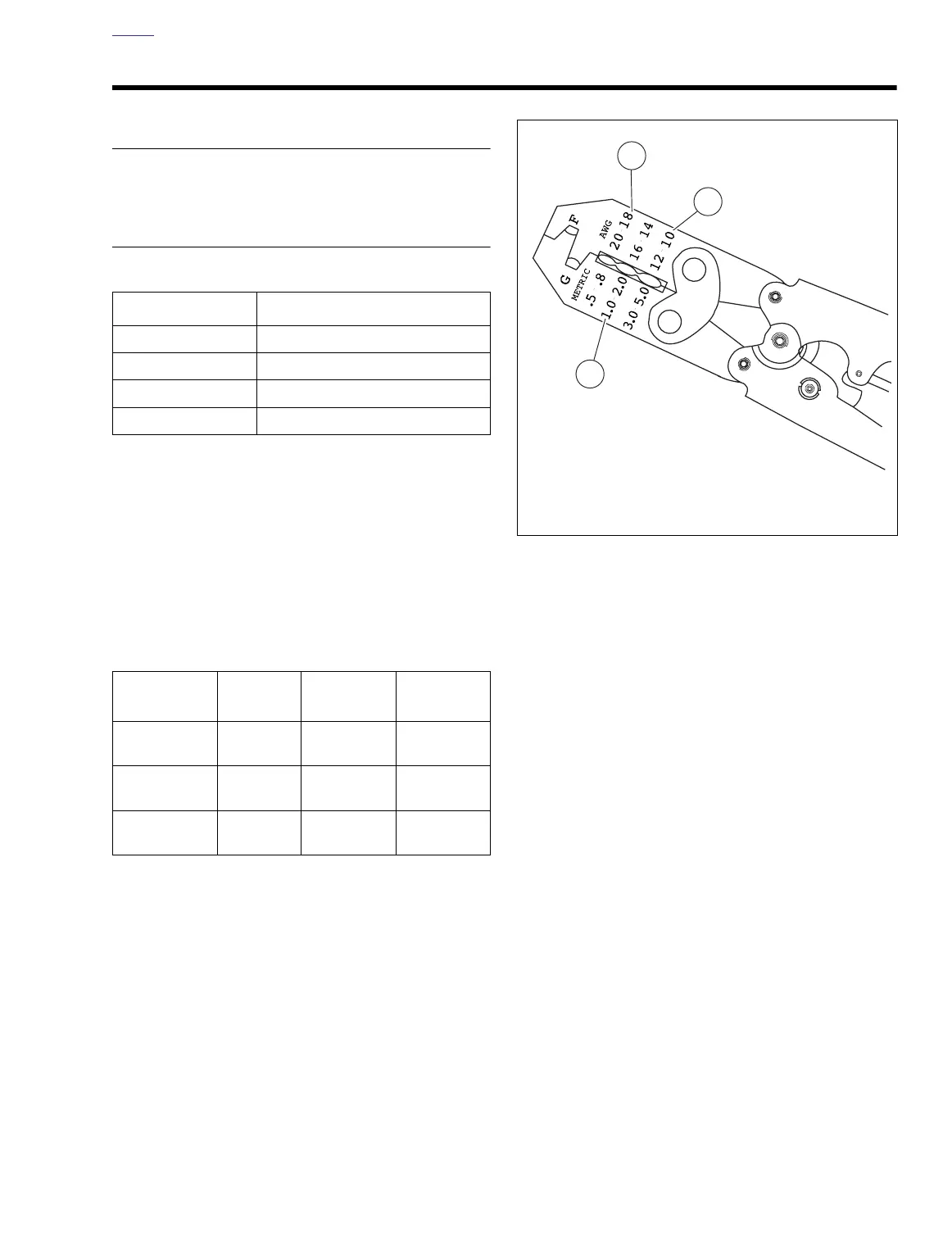

PART NO. SPECIALTY TOOL

HD-38125-8 Packard crimping tool

HD-39969 Ultra-torch

HD-25070 Heat gun

HD-41183 Heat shield attachment

Table B-5. Sealed Splice Connectors

Wire Gauge

Connector

Color

Connector

Part No.

Strip Length

18-20

(0.5-0.8 mm

Red 70585-93 3/8 in.

(9.5 mm)

14-16

(1.0-2.0 mm)

Blue 70586-93 3/8 in.

(9.5 mm)

10-12

(3.0-5.0 mm)

Yellow 70587-93 3/8 in.?

(9.5 mm)

Figure B-15. Packard Crimping Tool (HD-38125-8)

1. Red connector die

2. Blue connector die

3. Yellow connector die

Loading...

Loading...