B-12 Appendix B: Wiring

HOME

DEUTSCH STANDARD TERMINAL B.4

PREPARE WIRE LEAD

1. Use a shop gauge to determine gauge of wire lead.

2. Strip lead removing 5/32 inch (4.0 mm) of insulation.

CRIMP TERMINAL TO LEAD

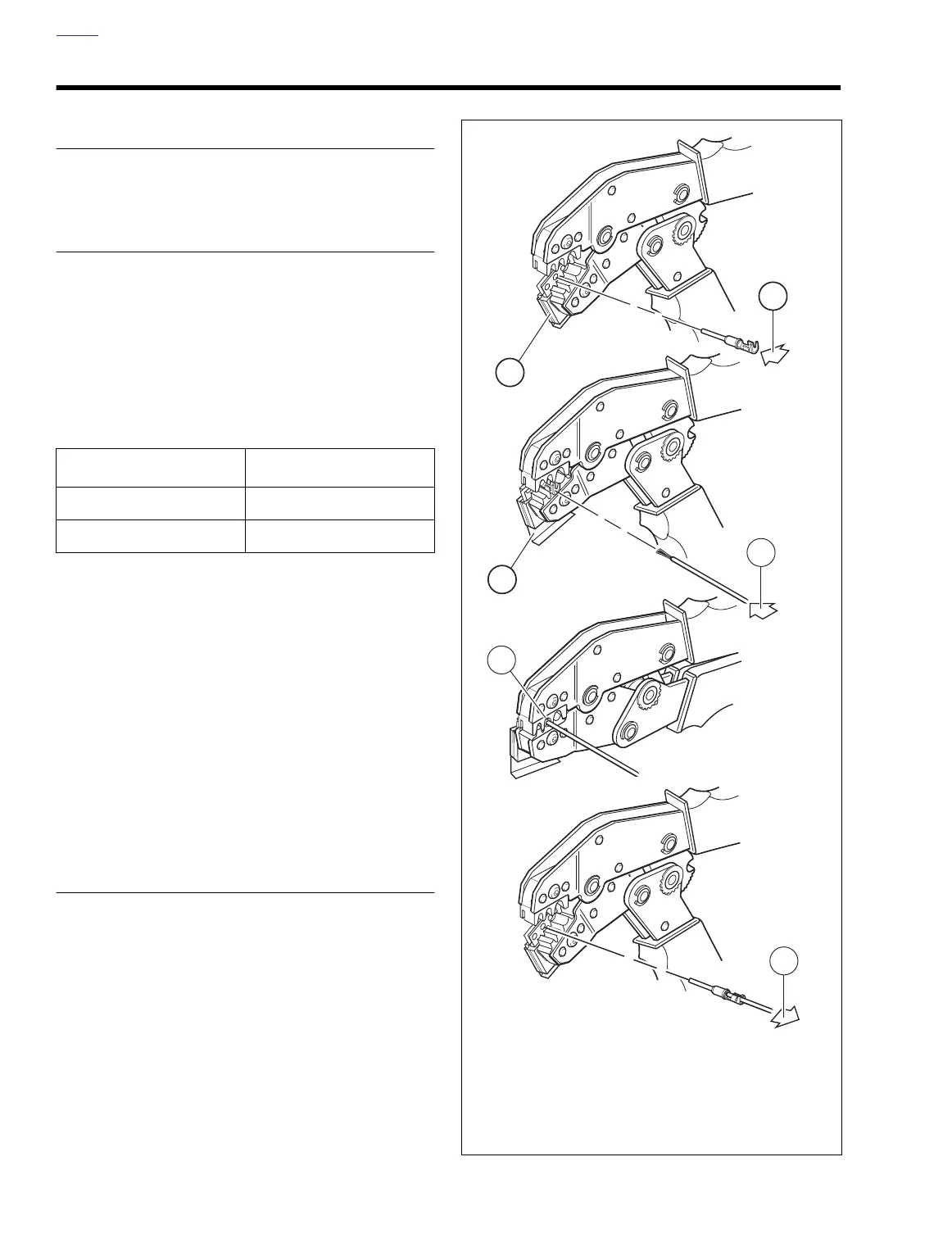

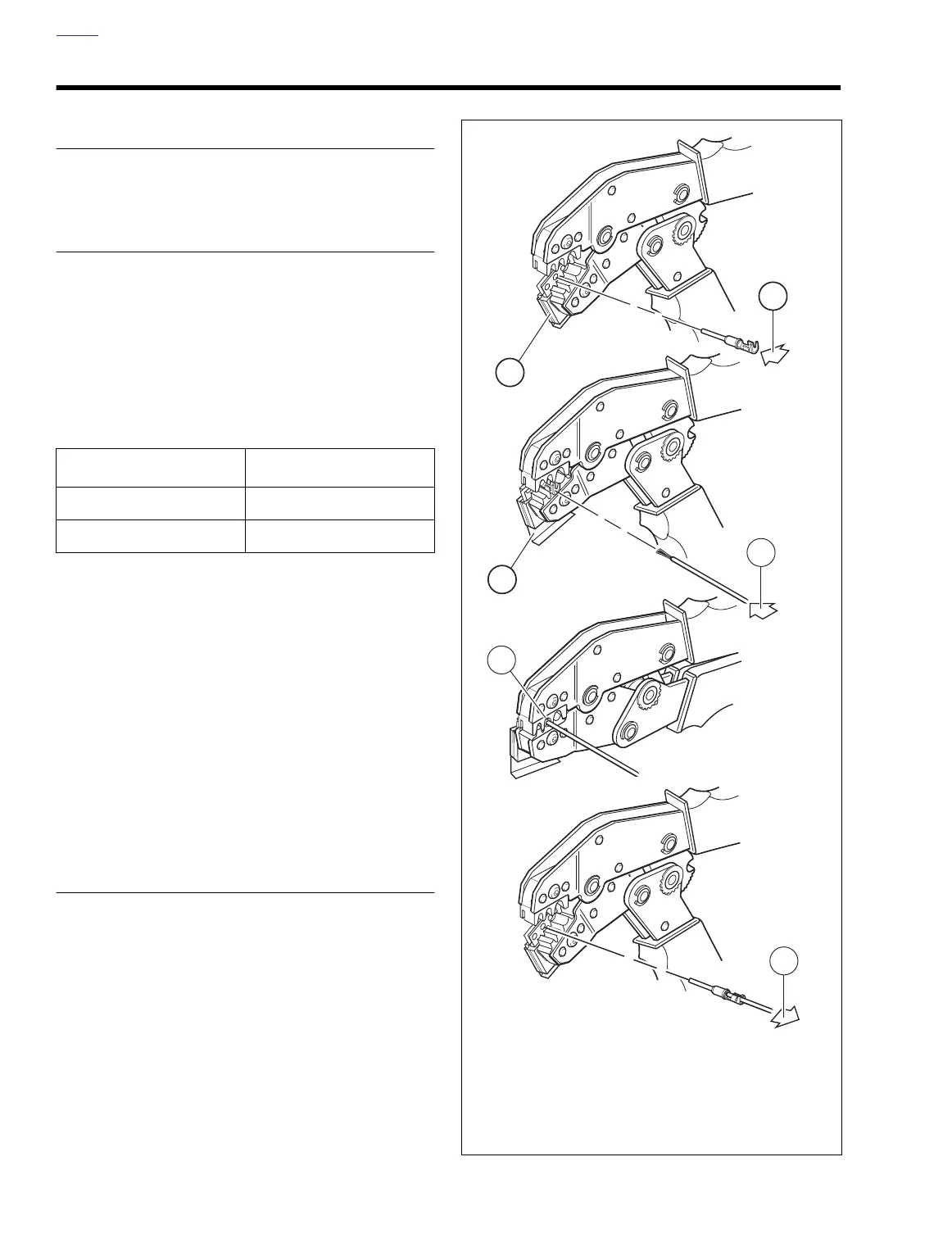

1. See Figure B-14. Squeeze the handles of the DEUTSCH

TERMINAL CRIMP TOOL (HD-39965) to open the jaws.

Push the locking bar (1) up.

2. Insert (2) terminal (socket/pin) through hole of the lock-

ing bar, so that the rounded side of the contact barrel

rests in the die (concave split level area) with the crimp

tails facing upward. To match the wire gauge to the crimp

tool die, refer to Table B-4.

3. Release locking bar to lock terminal in die.

NOTE

If the crimp tails are slightly out of vertical alignment, the

crimp tool automatically rotates the terminal so that the tails

face straight upward. When positioned, the locking bar fits

snugly in the space between the contact band and the core

crimp tails.

4. Insert stripped wire core between crimp tails until ends

make contact with locking bar. Verify that wire is posi-

tioned so that short pair of crimp tails squeeze bare wire

strands, while long pair folds over the insulation.

5. Squeeze handle of crimp tool until tightly closed. Tool

automatically opens after the terminal is crimped.

6. Raise locking bar up and remove wire lead and terminal.

INSPECT CRIMP

Inspect the wire core and insulation crimps. Distortion should

be minimal.

Table B-4. Wire Gauge to Die

Wire Gauge (AWG) Crimp Tool Die

20 Front

16-18 Middle

Figure B-14. Crimping a Deutsch Standard Terminal

2

5

4

6

1

3

f2501x1x

1. Open jaws and raise locking bar

2. Insert terminal in locking bar

3. Release locking bar to lock terminal in die

4. Insert stripped lead

5. Squeeze crimper

6. Raise locking bar and remove terminal

Loading...

Loading...