7-42 2007 Buell P3: Electrical

HOME

ASSEMBLY/INSTALLATION

Depending on whether the rotor, the stator, or both the rotor

and stator were removed/disassembled, perform the applica-

ble procedures which follow:

1. See Figure 7-54. Feed stator wiring with attached grom-

met into open grommet hole in left crankcase half.

2. Apply a light coating of clean engine oil or chaincase

lubricant to grommet. Install grommet into hole in left

crankcase half.

IMPORTANT NOTE

Stator TORX screws contain a thread locking compound.

Do not reuse existing screws. Always use new screws

with the proper thread locking compound. Loss of torque

on TORX fasteners could result in alternator damage.

3. Position stator on left crankcase half. Secure stator using

four

new

TORX screws. Tighten screws to 30-40

in-lbs

(3-5 Nm).

4. Route stator wiring under starter, behind footpeg support

bracket and under seat. Cable strap connector [46]

halves together.

NOTE

Temporarily attach a thin flexible “feed” or mechanic’s wire to

the connector end of the stator wiring to assist in the routing

of the wiring.

5. Connect alternator stator wiring to voltage regulator con-

nector [46] located behind left footrest support.

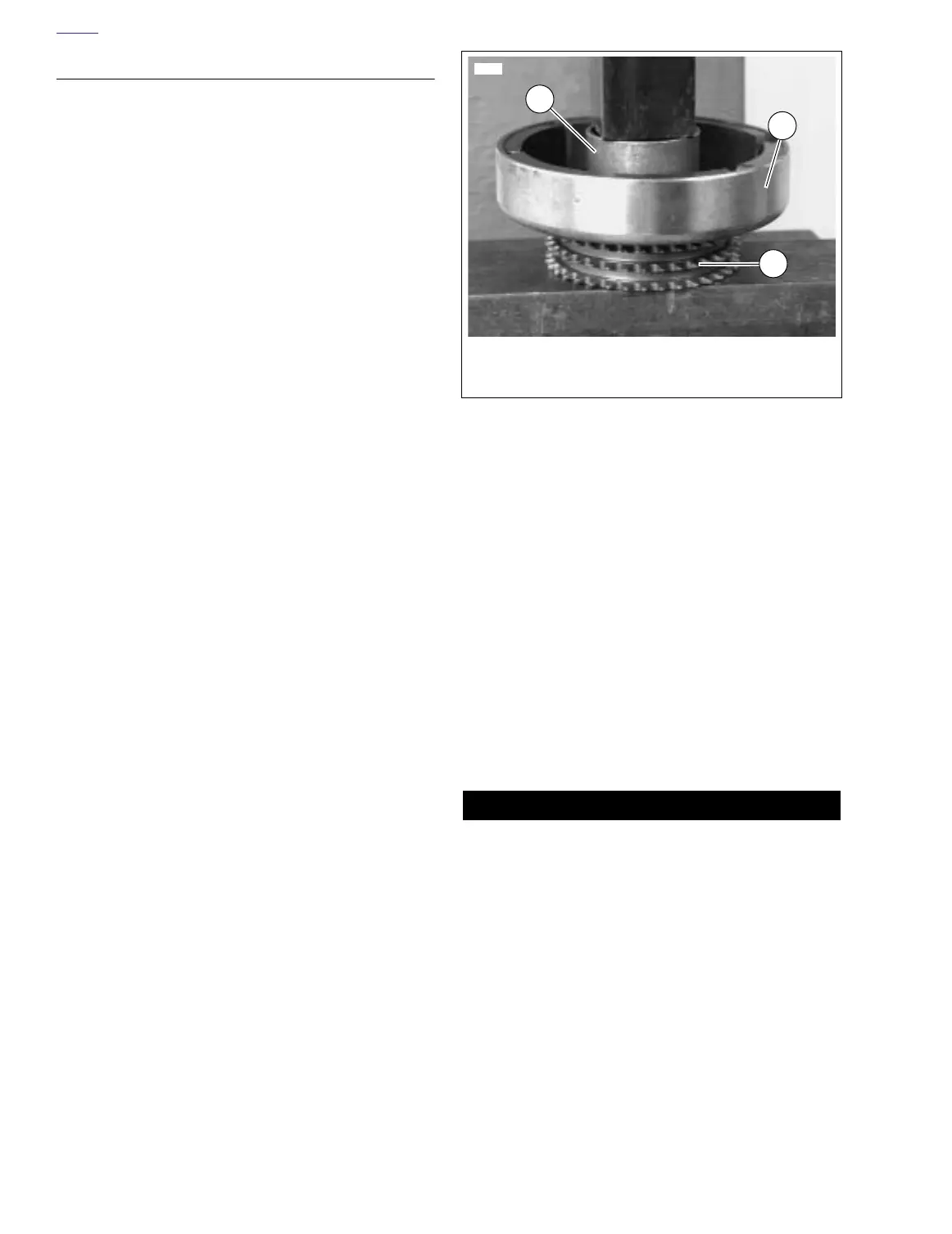

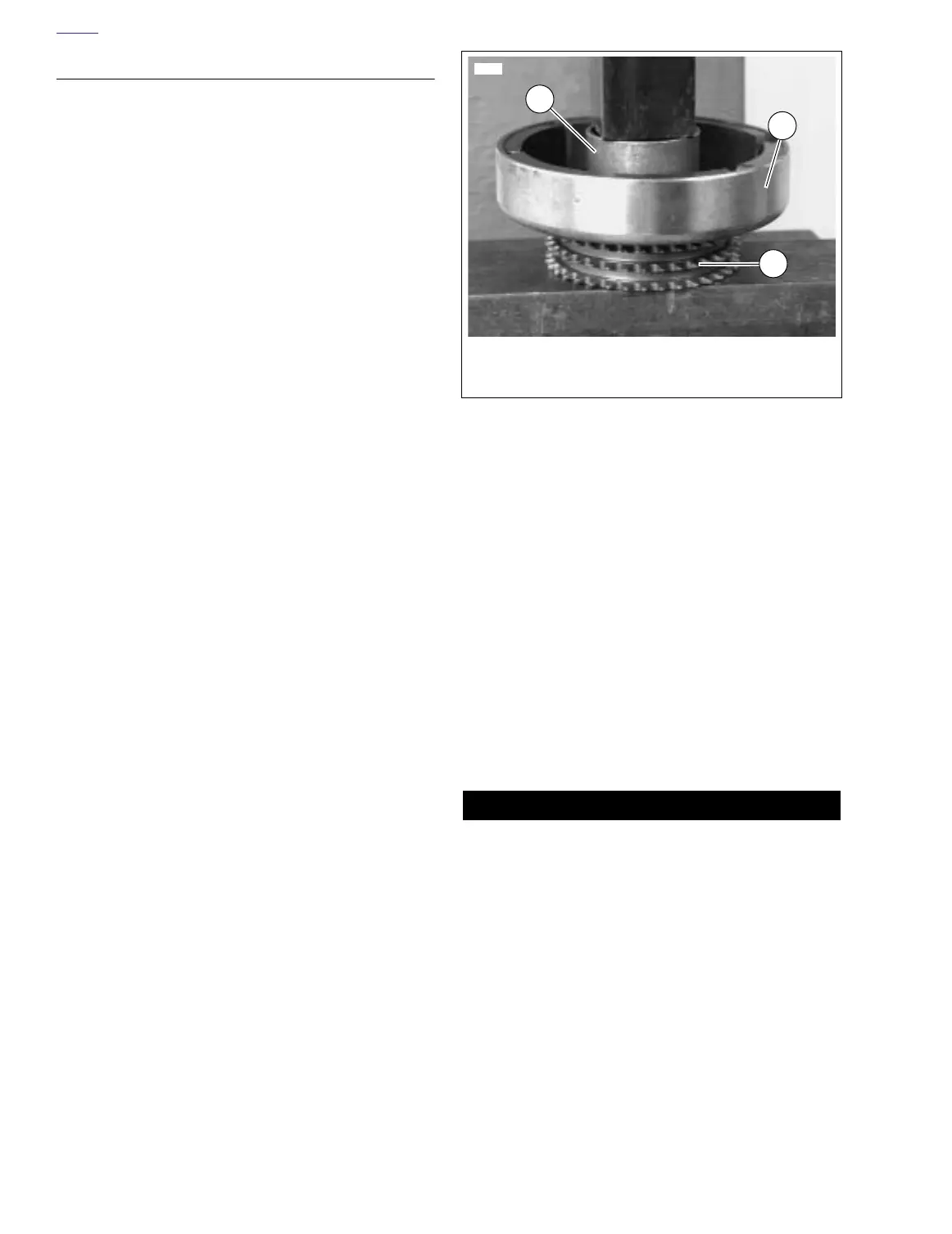

6. See Figure 7-55. Attach rotor to sprocket.

a. Position rotor on sprocket. Align holes in sprocket

with holes in rotor.

b. Apply a drop of Loctite 243 (blue) to threads of each

mounting bolt. Insert the eight mounting bolts

through rotor and start bolts into tapped holes in

sprocket.

c. Position a section of pipe with an inside diameter

larger than the sprocket mounting hub over center of

rotor. Press rotor onto sprocket. Tighten bolts to 90-

110

in-lbs

(10-12 Nm).

7. Install clutch assembly, primary chain and engine

sprocket/rotor assembly as a unit. See 6.4 PRIMARY

DRIVE/CLUTCH.

8. Install primary cover. See 6.2 PRIMARY CHAIN.

9. Connect negative battery cable to battery terminal.

Tighten fastener to 72-96

in-lbs

(8-11 Nm).

10. Test charging system. See 7.13 CHARGING SYSTEM.

11WARNING1WARNING

After installing seat, pull upward on front of seat to be

sure it is in locked position. While riding, a loose seat can

shift causing loss of control, which could result in death

or serious injury. (00070a)

11. Install seat. See 2.28 SEAT.

Figure 7-55. Pressing Rotor onto Sprocket

7806

1. Pipe section

2. Rotor

3. Sprocket

2

1

3

Loading...

Loading...