7-MAINTENANCE

Torque-Hydraulictubesandttings-Standardtorquedataforhydraulics

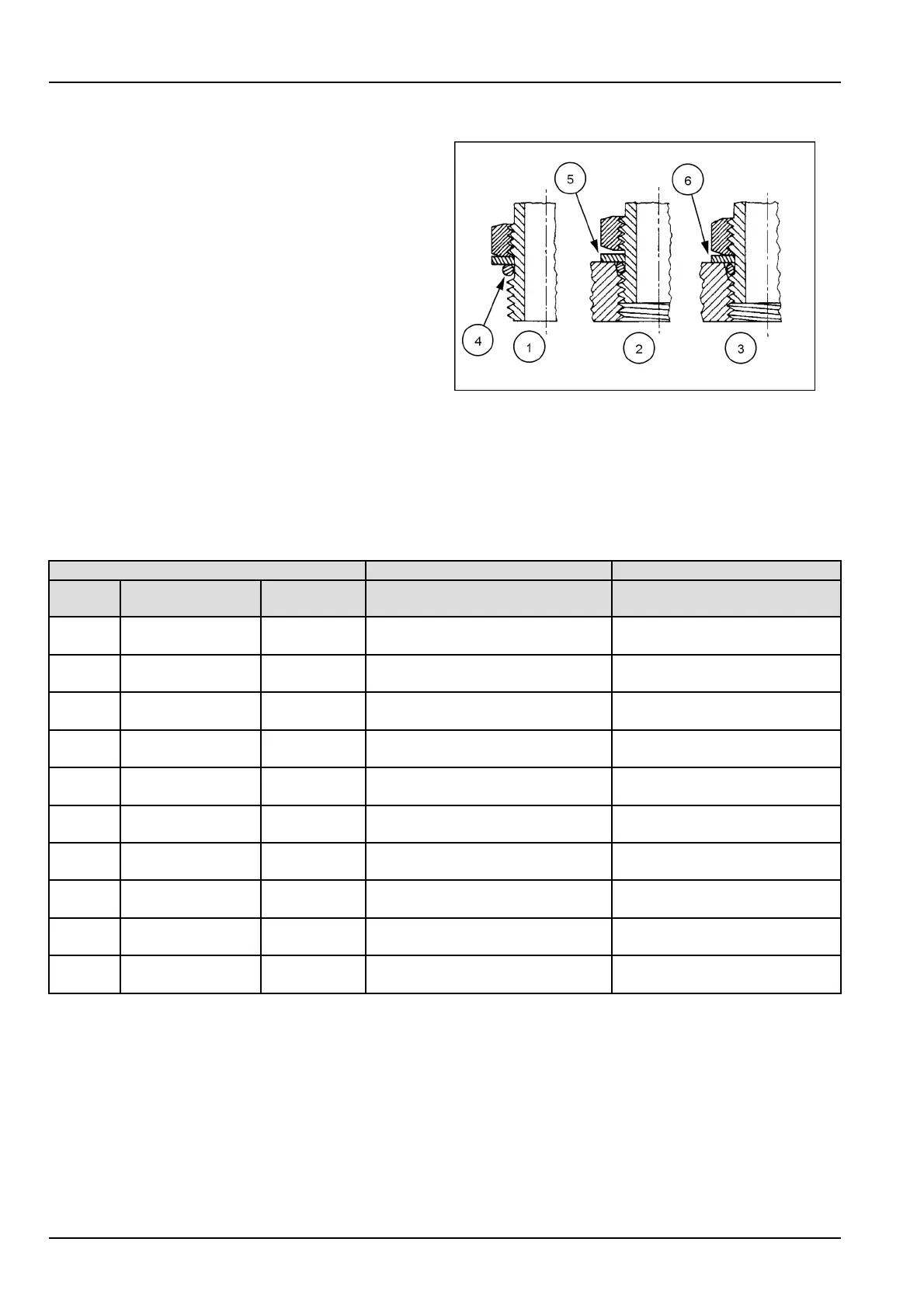

Installationofadjustablettingsinstraight

threadO-ringbosses

1.LubricatetheO-ringbycoatingitwithalightoilor

petroleum.InstalltheO-ringinthegrooveadjacent

tothemetalbackupwasherwhichisassembledatthe

extremeendofthegroove(4).

2.InstallthettingintotheSAEstraightthreadbossuntil

themetalbackupwashercontactsthefaceoftheboss

(5).

NOTE:Donotovertightenanddistortthemetal

backupwasher.

3.Positionthettingbyturningout(counterclockwise)

uptoamaximumofoneturn.Holdingthepadofthe

ttingwithawrench,tightenthelocknutandwasher

againstthefaceoftheboss(6).

230856591

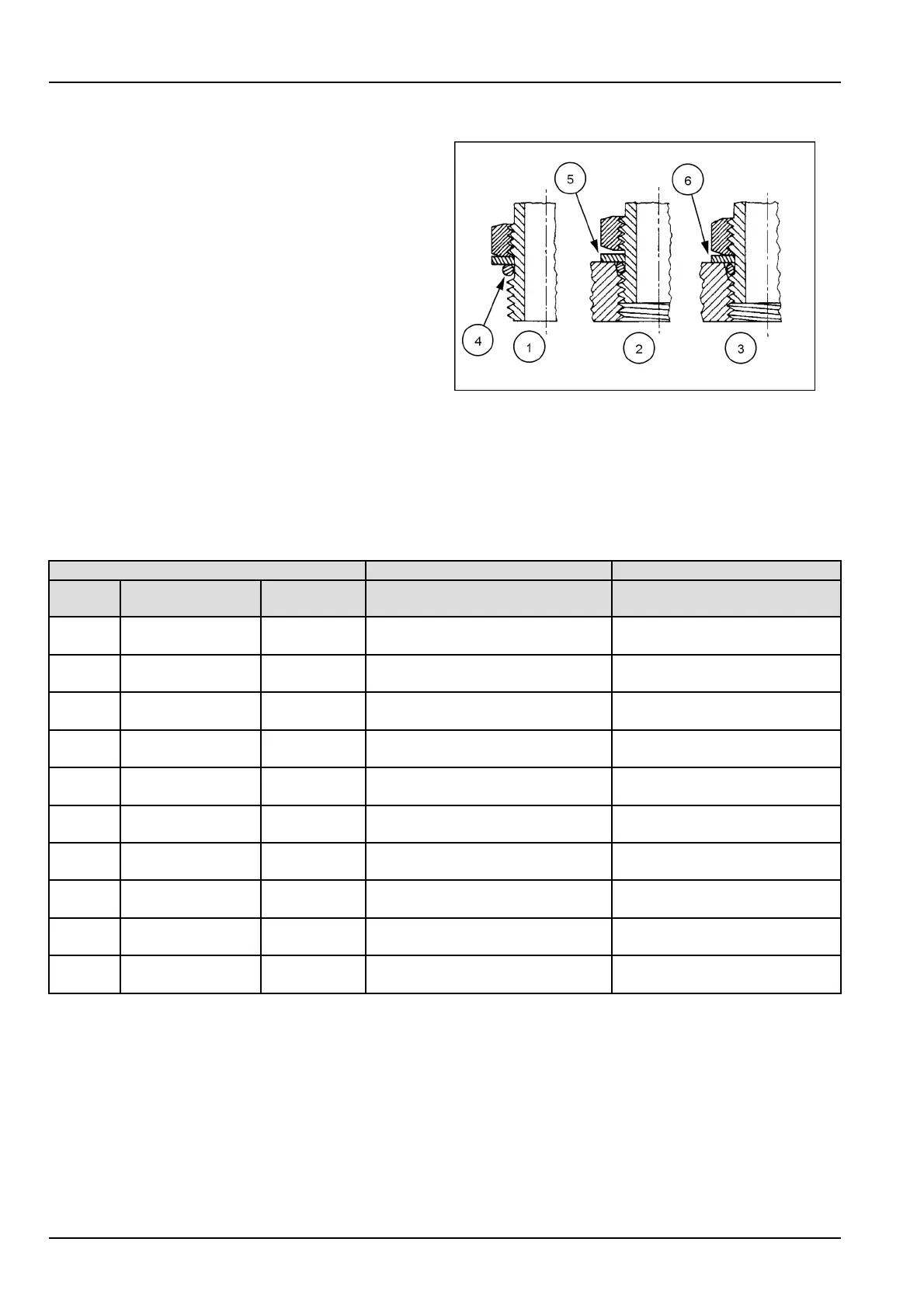

Standardtorquedataforhydraulictubesandttings

Standardtorquedataforhydraulictubesandttings

37°arefemaleswivelStraightthreadO-ringboss

Dash

Size

TubingOD

ThreadsizeTorqueTorque

-46.4mm

(1/4in)

7/16-20

15-16N·m

(11-12lbft)

18-26N·m

(13-19lbft)

-5

7.9mm

(5/16in)

1/2-20

19-21N·m

(14-15lbft)

23-26N·m

(17-19lbft)

-69.5mm

(3/8in)

9/16-18

24-28N·m

(18-21lbft)

29-40N·m

(21-30lbft)

-812.7mm

(1/2in)

3/4-16

49-53N·m

(36-39lbft)

49-57N·m

(36-42lbft)

-1015.9mm

(5/8in)

7/8-14

77-85N·m

(57-63lbft)

59-90N·m

(44-66lbft)

-1219.1mm

(3/4in)

1-1/16-12

107-119N·m

(79-88lbft)

93-128N·m

(69-94lbft)

-1422.2mm

(7/8in)

1-3/16-12

127-140N·m

(94-103lbft)

122-134N·m

(90-99lbft)

-1625.4mm

(1in)

1-5/16-12

147-154N·m

(108-114lbft)

151-174N·m

(111-128lbft)

-2031.8mm

(1-1/4in)

1-5/8-12

172-181N·m

(127-133lbft)

198-218N·m

(146-161lbft)

-2438.1mm

(1-1/2in)

1-7/8-12

215-226N·m

(159-167lbft)

209-235N·m

(154-173lbft)

Thesetorquesarenotrecommendedfortubesof12.7mm(1/2in)ODandlargerwithwallthicknessof0.889mm

(0.035in)orless.Thetorqueisspeciedfor0.889mm(0.035in)walltubesoneachapplicationindividually.

Beforeinstallingandtorquing37°aredttings,cleanthefaceoftheareandthreadswithacleansolventorLoctite

cleanerandapplyhydraulicsealant

LOCTITE®569™tothe37°areandthethreads.

Installttingandtorquetospeciedtorque,loosenttingandretorquetospecications.

7-6

Loading...

Loading...