7-MAINTENANCE

Replacehydraulicoillters(Initial)

WARNING

Pressurizedhydraulicuidcanpenetratetheskinandcausesevereinjuries.

Hydraulicuidisunderextremepressure.Restthebucketorattachmentontheground.Shutthe

engineoff,turnthekeyon,andmovethehydrauliccontrolleverthroughallmovementsseveraltimes

torelieveresidualpressureinthesystem.

Failuretocomplycouldresultindeathorseriousinjury.

W0161A

WARNING

Pressurizeduidcanpenetratetheskinandcausesevereinjuries.

Keephandsandbodyawayfromanypressurizedleak.DONOTuseyourhandtocheckforleaks.Use

apieceofcardboardorpaper.Ifuidpenetratestheskin,seekmedicalattentionimmediately.

Failuretocomplycouldresultindeathorseriousinjury.

W0158A

Replacethehydraulicoillterwhenthehourmeterregisters100hoursforanewmachineduringtheinitialrun-in

period.Theltershouldbechangedevery2000hoursthereafterormorefrequentlywhenoperatingconditionsare

severe.

Prioroperation:

Keepallunauthorizedpersonnelclearofthearea.Parkthemachineonlevelground,inneutralwiththeparkingbrake

applied,andtheattachmentloweredtotheground,turnofftheengine,removethekey,andverifythatenginecom-

ponentshavecooledoravoidcontact.Makesurethatallresidualpressureisrelievedfromcircuitsbeforebeginning

maintenance.

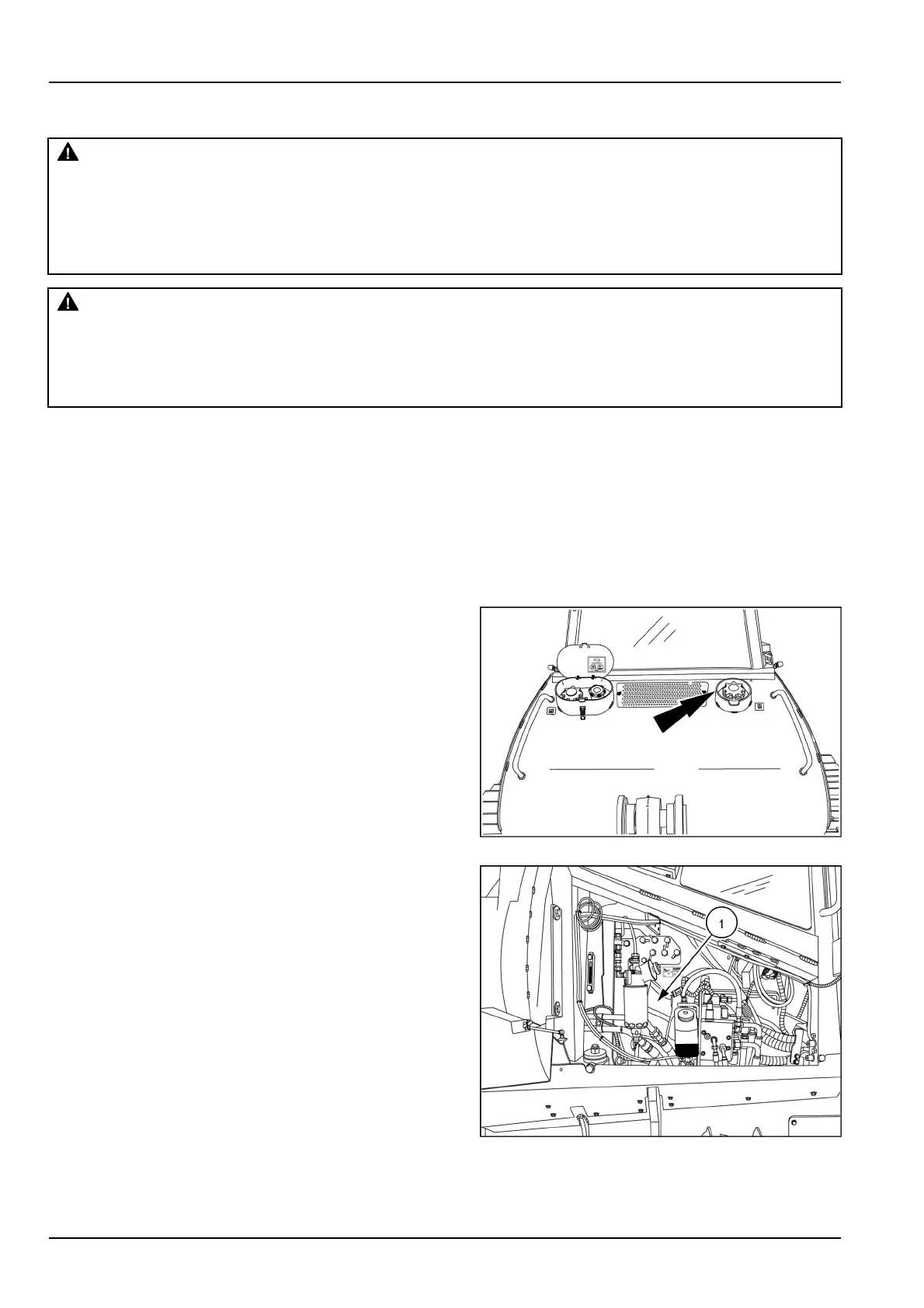

1.Thehydraulicoilllercapislocatedontherearofthe

machine.

2.Stoptheengine.PutaDoNotOperatetagonthekey

switch.

3.Makesuretheaccumulatorsonthemachinearecom-

pletelydischarged.

4.Cleantheareaaroundthehydraulicoilllercap,and

slowlyloosenthecaptoreleaseanyremainingpres-

sure.

RAPH12DOZ128AA1

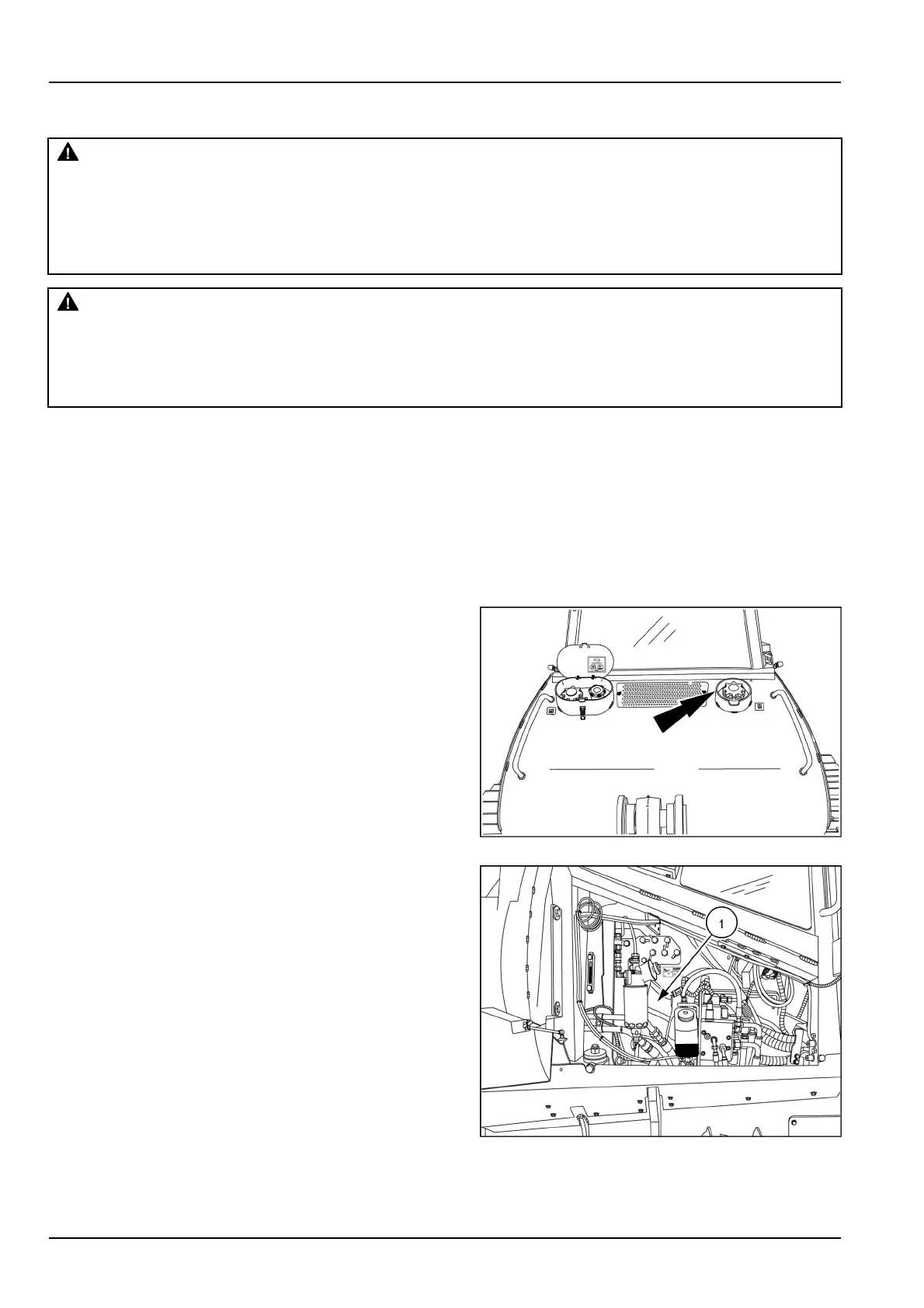

5.Removeandreplacethehydraulicoillter(1).Turnthe

ltercounterclockwisetoremove.

6.Cleanthecontactsurfaceonthelterhead.Makesure

thatalldirtandgasketmaterialhasbeenremoved.

7.Applyathincoatofcleanoiltothehydraulicoilgasket

andthreads.

8.Installandtightenthenewltercartridgermlytothe

lterheadbyhand.Donotusealterwrenchtotighten

thelter.

RAIL13DOZ1266AA2

7-44

Loading...

Loading...