7-MAINTENANCE

Pipethreadttingtorque

Beforeinstallingandtighteningpipettings,cleanthe

threadswithacleansolventorLoctitecleanerandapply

sealantLOCTITE®567™PSTPIPESEALANTforallttings

includingstainlesssteelor

LOCTITE®565™PSTfor

mostmetalttings.Forhighltration/zerocontamination

systemsuseLOCTITE®545™.

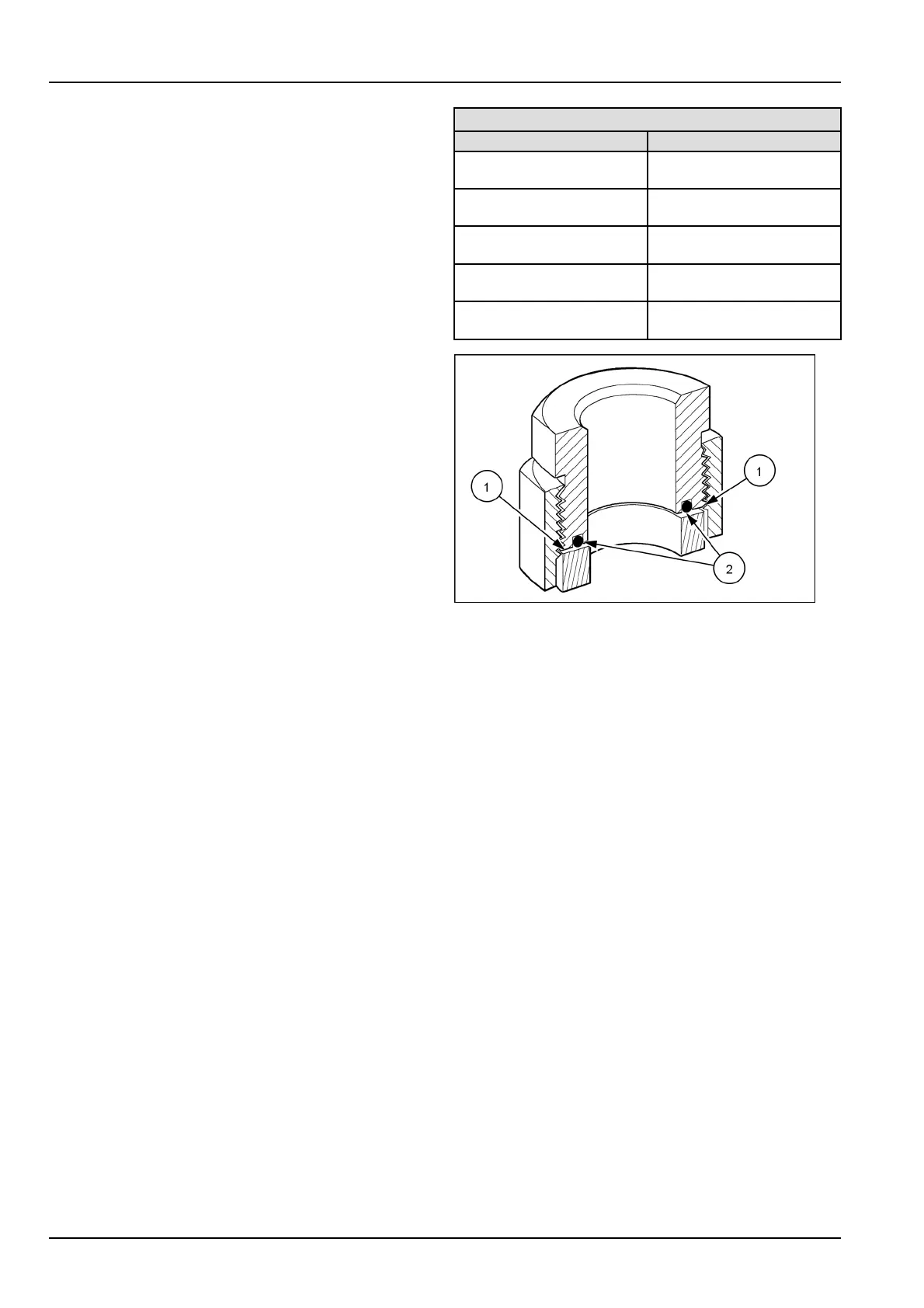

Pipethreadtting

ThreadSize

Torque(Maximum)

1/8-27

13N·m

(10lbft)

1/4-18

16N·m

(12lbft)

3/8-18

22N·m

(16lbft)

1/2-14

41N·m

(30lbft)

3/4-14

54N·m

(40lbft)

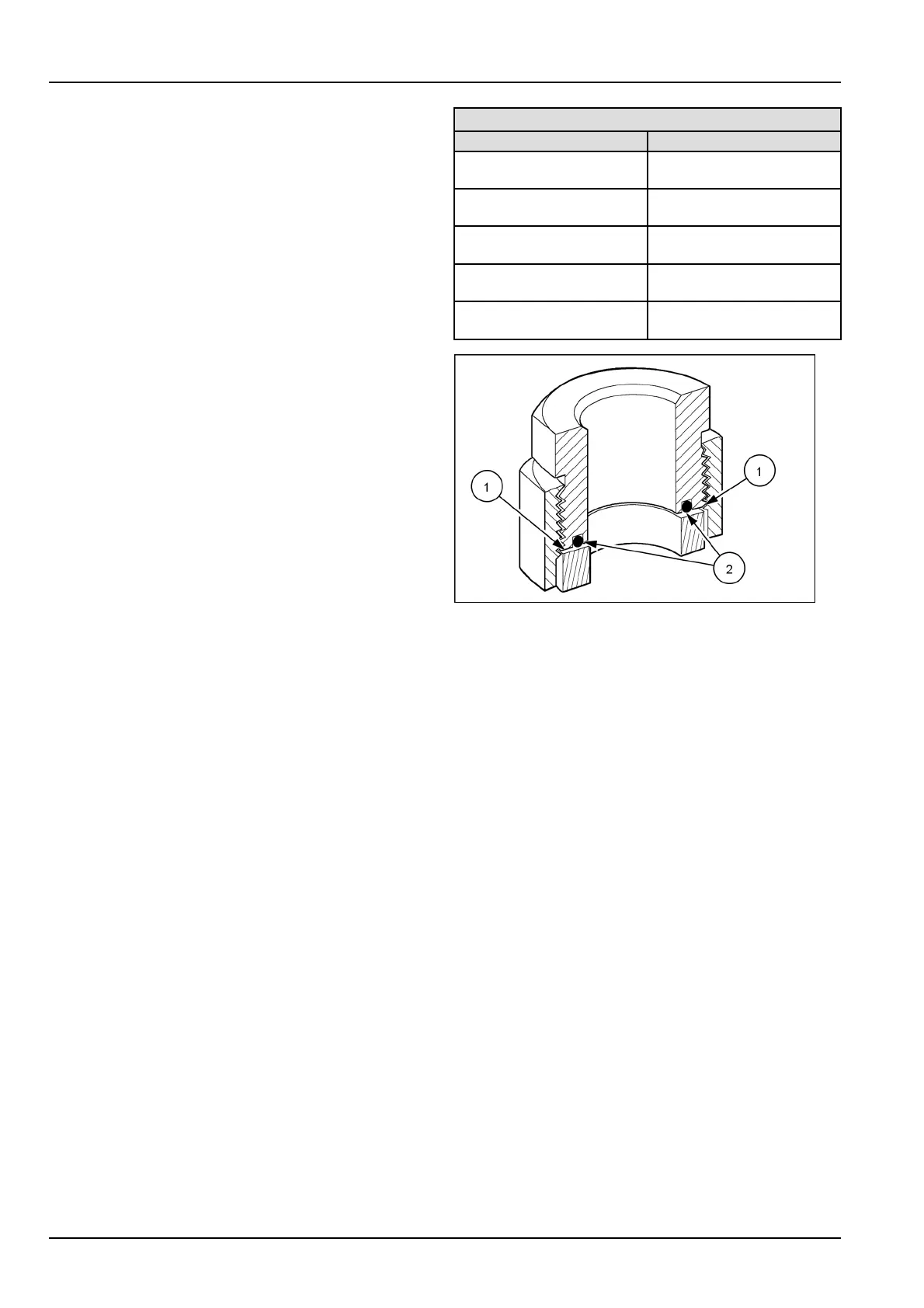

InstallationofORFS(O-ringatfaced)t-

tings

WheninstallingORFSttingsthoroughlycleanbothat

surfacesofthettings(1)andlubricatetheO-ring(2)with

lightoil.Makesurebothsurfacesarealignedproperly.

Torquethettingtospeciedtorquelistedthroughoutthe

repairmanual.

NOTICE:Ifthettingsurfacesarenotproperlycleaned,

theO-ringwillnotsealproperly.Ifthettingsurfacesare

notproperlyaligned,thettingsmaybedamagedandwill

notsealproperly.

NOTICE:Alwaysusegenuinefactoryreplacementoils

andlterstoensureproperlubricationandltrationofen-

gineandhydraulicsystemoils.

Theuseofproperoils,grease,andkeepingthehydraulic

systemcleanwillextendmachineandcomponentlife.

500111832

7-8

Loading...

Loading...