7-MAINTENANCE

Increasethetracktension

Usethetrackadjustergreasettingtoadjusttrackten-

sion.Addinggreasewillincreaseandtightenthetrack

deection.

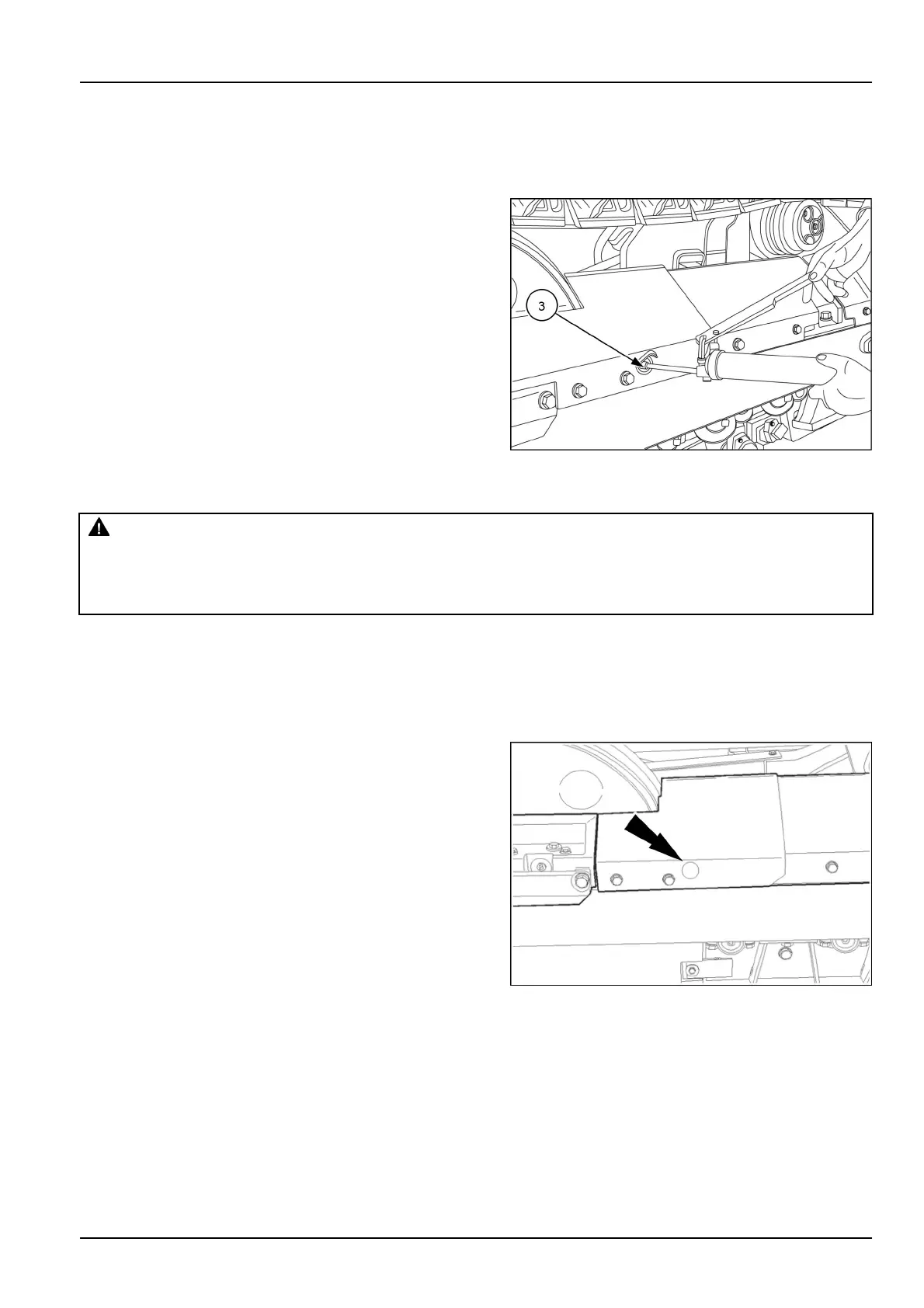

1.PumpTUTELAMOLYGREASEGR-75intothetting(3)

untildeectioniscorrect.

2.Inastraightpath,movethemachinebackwardthe

lengthofthetrack,andthenforwardthelengthofthe

track.Thiswillensurethatthebottomofthetrackis

tight.Bringthemachineslowlytoastop.Donotuse

thebrakestostop.

3.Bringthemachineslowlytoastop.Donotusethe

brakestostopthemachine.

4.Checkthedeectionofthetrackagainandadjust,if

necessary.

5.Repeattheprocedurefortheothertrack.

RAIL12DOZ0374AA3

Decreasethetracktension

WARNING

Flyingobject!

Alwaysweareyeorfullfaceprotectionwhenperformingthisprocedure.

Failuretocomplycouldresultindeathorseriousinjury.

W0313A

Decreasethetracktensionwithanadjustmenttothe

ballchecktting.

ThegreaseisUNDEREXTREMEPRESSURE.Be

carefultobacktheballcheckadjustmentoffSLOWLY .

Wearfullcoveragefaceprotectionbeforeproceeding.

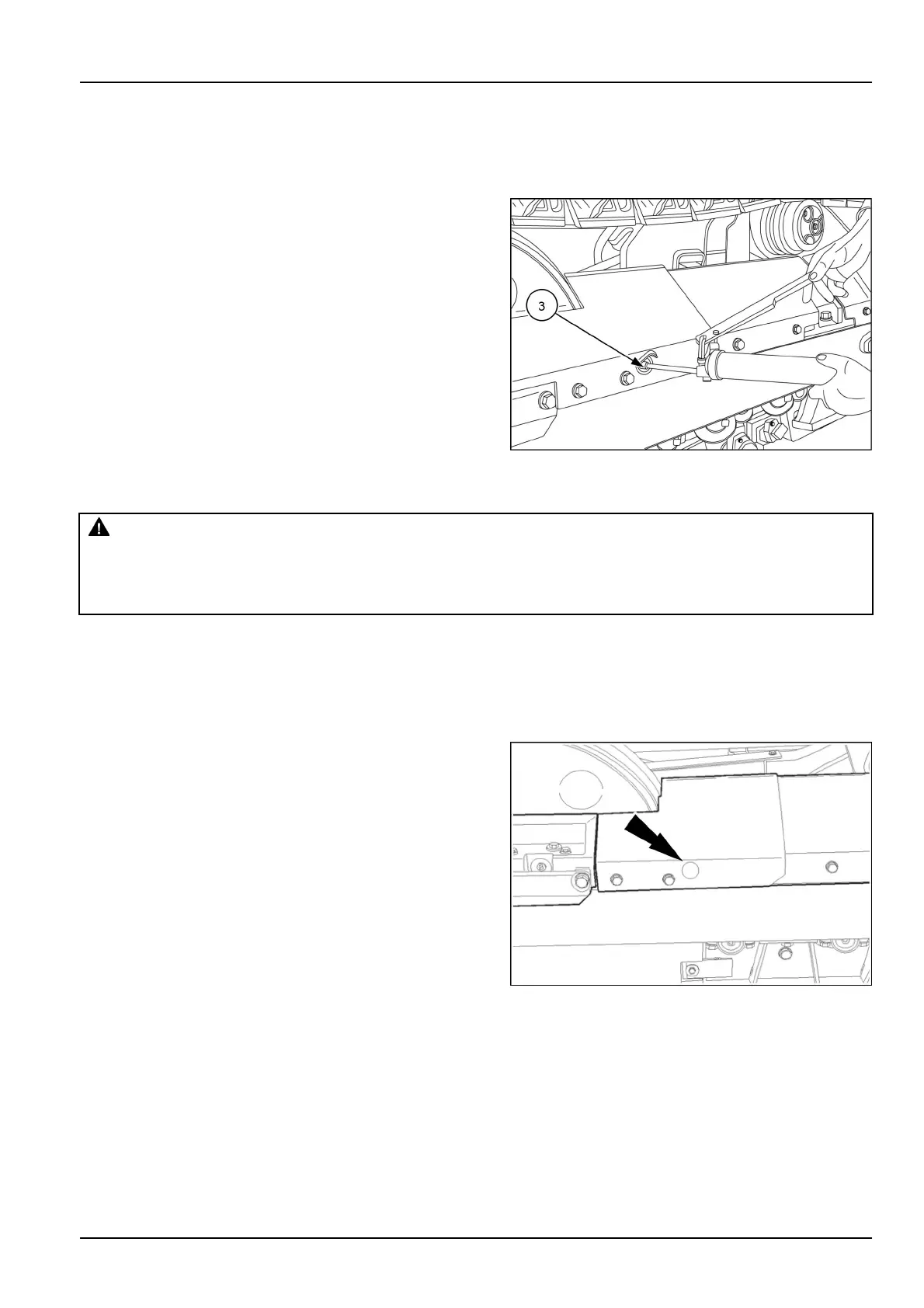

1.Usea3/4indeepsocket,andloosentheballcheck

ttingSLOWLYabouttwoturns.DONOTremovethe

adapter.Allowthegreasetoevacuateuntilthetrack

deectioniswithintheproperrange.

2.Whencomplete,re-torquetheballcheckto59.7-

74.6N·m(44-55lbft).

3.Inastraightpath,movethemachinebackwardthe

lengthofthetrack,andthenforwardthelengthofthe

track.Thiswillensurethatthebottomofthetracktight.

Donotusethebrakestostopthemachine.

4.Bringthemachineslowlytoastop.Donotusethe

brakestostopthemachine.

5.Recheckthetracktension.

6.Repeattheprocedurefortheothertrack.

RCIL10CWL080AAL4

7-51

Loading...

Loading...