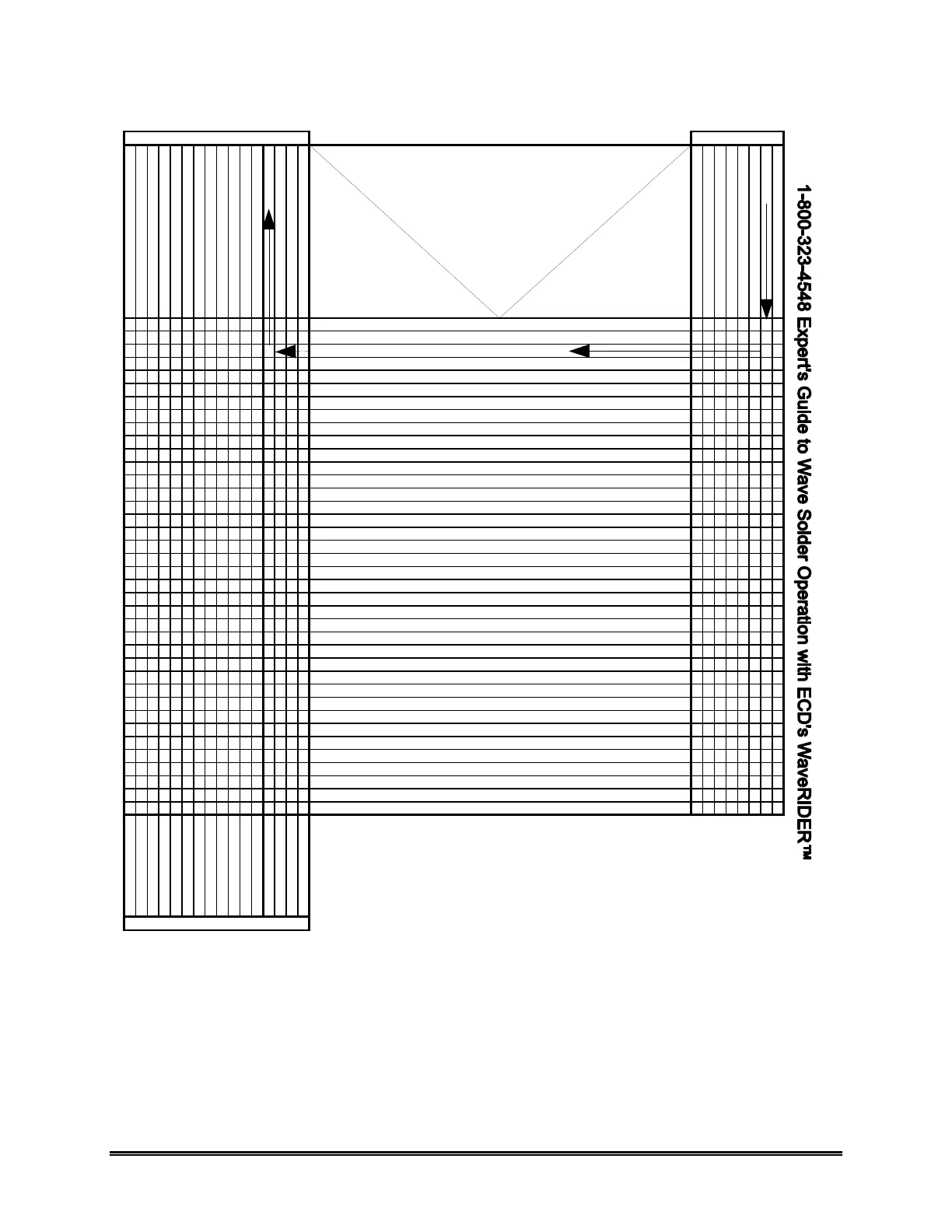

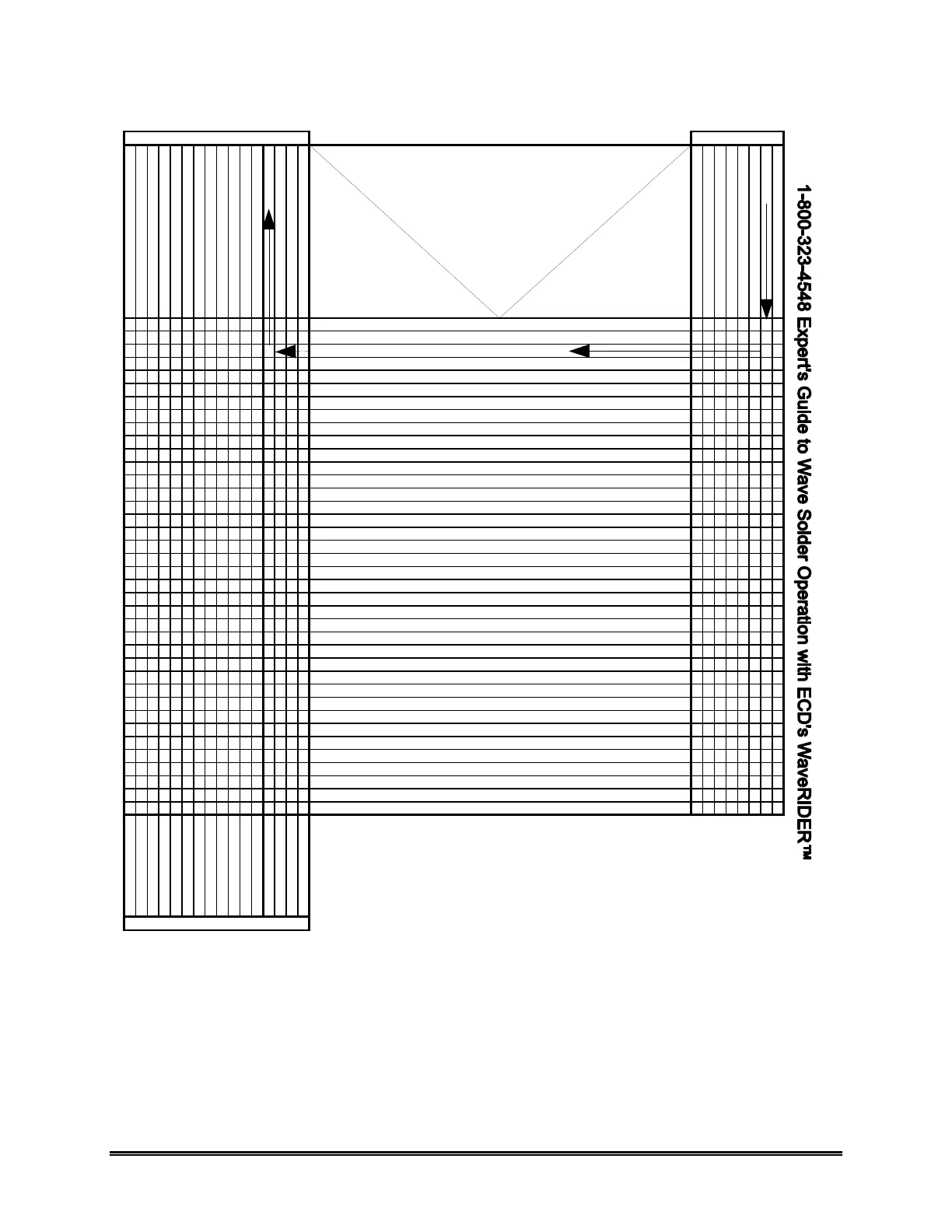

26 WaveRIDER

WaveRIDER Parameter (3) Problem (1)

A36-9283-06 Rev 1.2

Solder Wave Contact Lengths (A, B, C)

Solder Wave Dwell Times (A, B, C)

Chip Wave Contact Lengths (A, B, C)

Chip Wave Dwell Times (A, B, C)

Conveyor Speed

Potential Cause (2)

Solder Bridges

Conveyor speed too fast….Reduces dwell time in wave and forces preheat to be to high

3

Preheat temp low….Solder pads not within 100°F of solder wave temperature

3

1

2

1

2

3

Conveyor speed too low….increases dwell time in solder wave

3

Carrier bent or damaged….Board must run parallel (flat) over wave

3

Conveyor fingers bent….Board may not be parallel over solder wave

2

Flux applied is insufficient….Spotty application or weak activity flux

2

Rails not parallel (flat) over nozzles….One side of board deeper in solder wave than the other

2

Wave or nozzles not level….Must be parallel to conveyor

1

Wave height/exit incorrectly set….Exit speed of solder should match conveyor speed

3

Board not run in best direction….Component shadowing

1

Dross recirculating from pot to wave….Excessive dross build up

1

Air knife after wave set incorrectly….Air knife not effectively blowing off excess solder

1

< 0.3 sec

0.062

2.0 inches

3 sec

495°F

100°F

< 0.3 sec

.062 inches

0.5 inches

1 sec

495°F

N/A

4 ft/Min

5°F/Sec

Room Temp

225°F

3 = High Impact

2 = Moderate Impact

1 = Low Impact

Typical Values

Figure 3- 6: Troubleshooting Process

Loading...

Loading...