connected to the pump via the nEXT pump power supply cable when accelerang and

running.

Whils

t decelerang the pump will coast down and no power will be returned to the

electrical supply.

The electronic braking opon may be enabled to reduce the pump deceleraon me

and to recover some energy from the pump. This is only achieved by returning power

from the pump to the electrical supply through the nEXT pump power supply cable. The

rate at which electrical energy is returned to the supply is regulated to the voltages

shown:

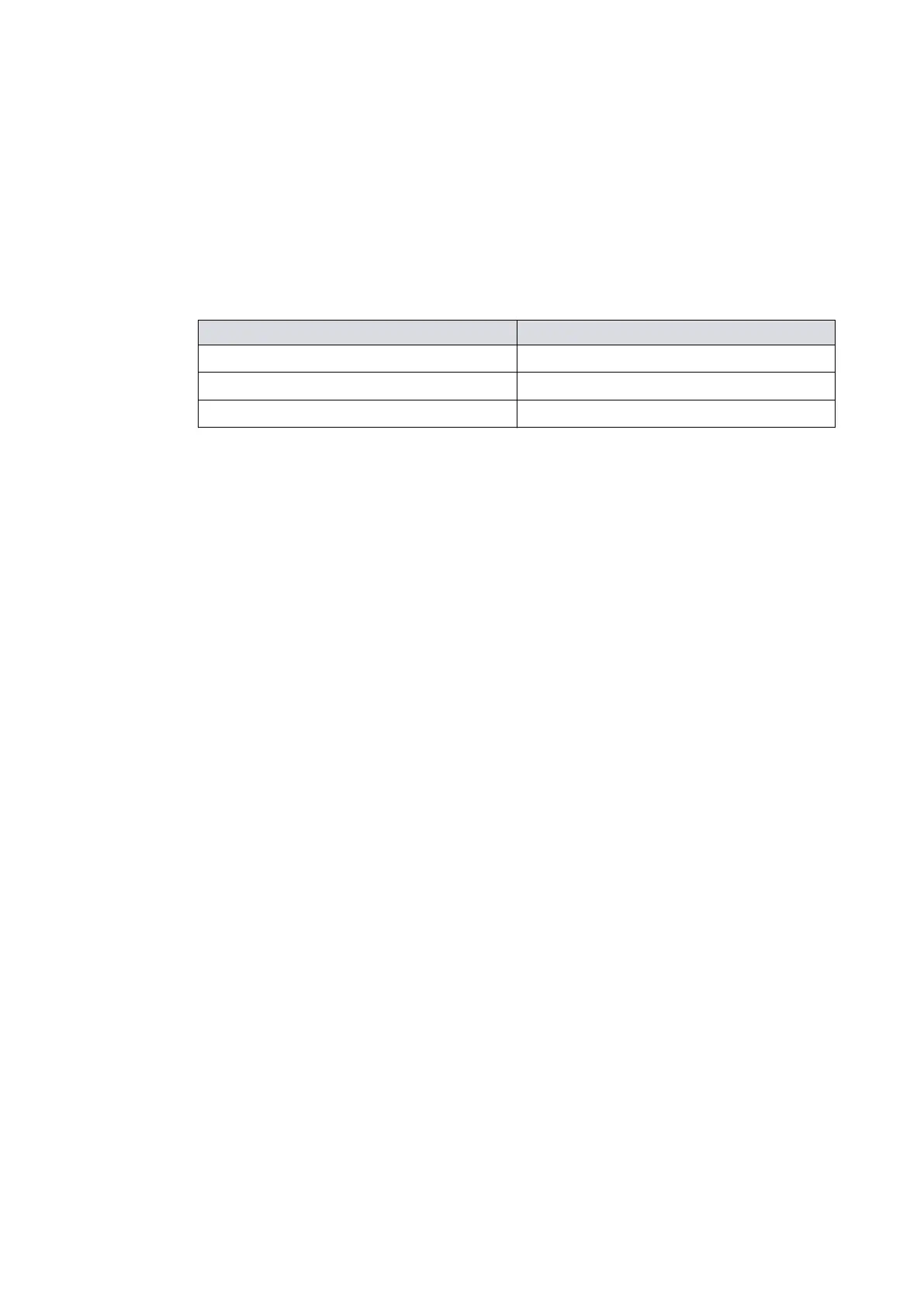

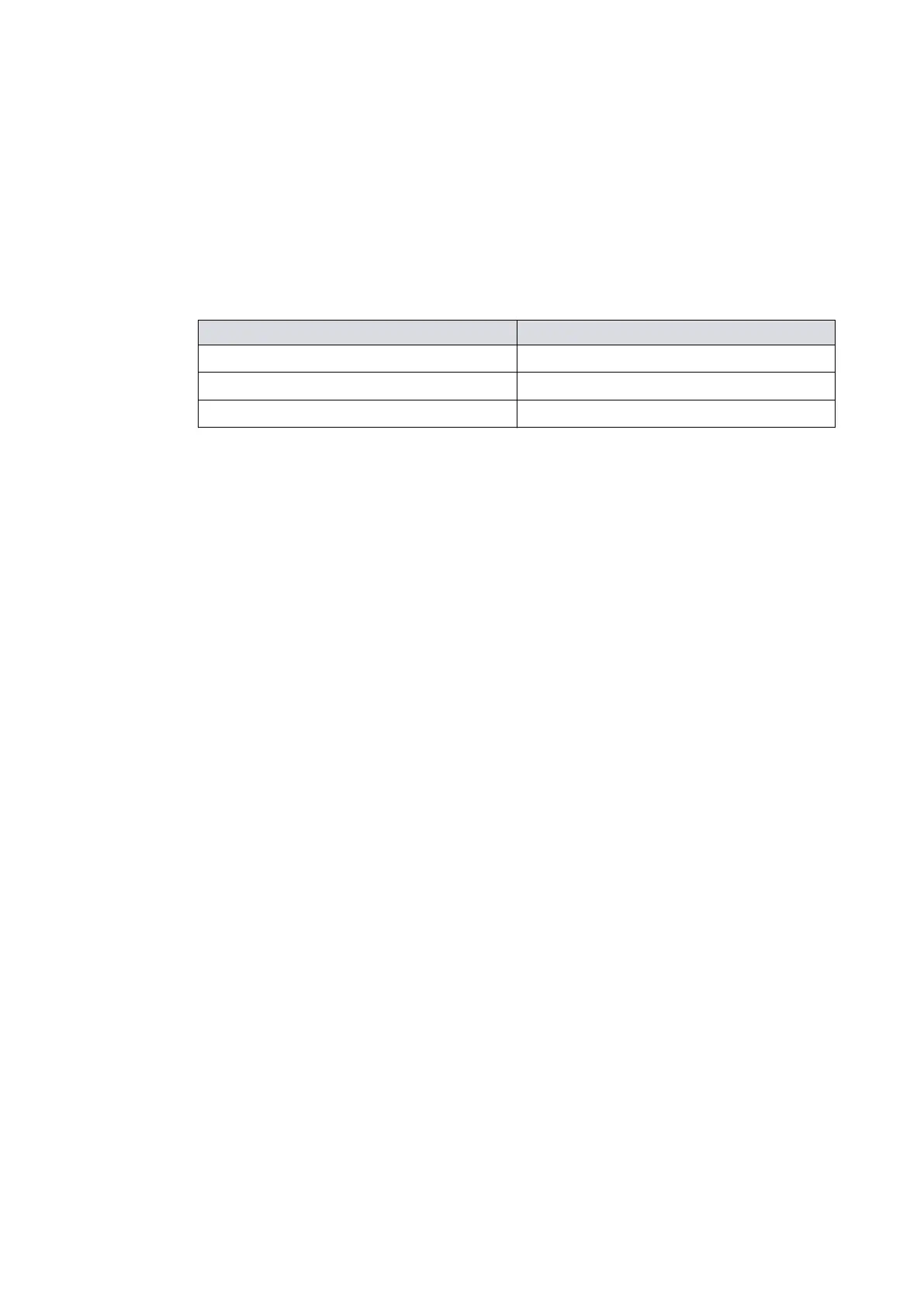

Voltage range Returned electronic braking voltage

Below 43.2V dc. (48V dc. –10%) Outside working range for pump

43.2V dc. to 50.4V dc. 48 V d.c. + 10%

Above 50.4V dc. (48V dc. +5%) Outside working range for pump

In order to achieve the fastest electronic braking mes there must be somewhere for the

returned power to go, such as:

▪ A supply capable of receiving the returned power

▪ Other devices sharing the same electrical supply bus with the pump

▪ A suitable 3 A load when decelerang the pump

3.3.8 Bearing monitoring

In order to ensure maximum reliability and bearing life the nEXT pumps have an

integrated system to manage the bearing condion, refer to Bearing monitoring and

condioning system on page 106. The pumps have an integrated baery backed real

me clock that is constantly monitoring pump storage me.

If the pump is stored without being run for more than 12 months "Bearing Run in Mode

on page 107" (BRIM) is triggered the next me the pump is started to condion the

bearing. Bearing run in mode (BRIM) is a start-up sequence for the pump designed to

precondion the bearing to opmise bearing life. The pump goes through a number of

speed steps before reaching full speed.

3.4 Logic interface

The motor controller can only be operated through the logic interface. There are three

types of signals on the logic interface.

▪ Control inputs: these are switch‑type signals that ar

e used to control the pump

▪ Status outputs: these outputs idenfy the status of the system

▪ Analogue output: this provides a 0 ‑ 10 V output for a number of pump

par

ameters.

The logic interface has been designed to support both serial and parallel control and

monitoring, operang through one connector. For serial control either RS232 (default) or

RS485 can be selected using the RS485/CAN/RS232 slide switch located on the motor

controller (refer to Connecon for serial control and monitoring on page 59).

The logic interface can be plugged directly into the Edwards TIC Turbo Controller, TIC

Turbo Instrument Controller or TAG Controller and then use the funconality that they

08/2021 - ©Edwards Limited

Page 18B8J200880_D

300812671_002_C3

B8J200880_D - Overview

Loading...

Loading...