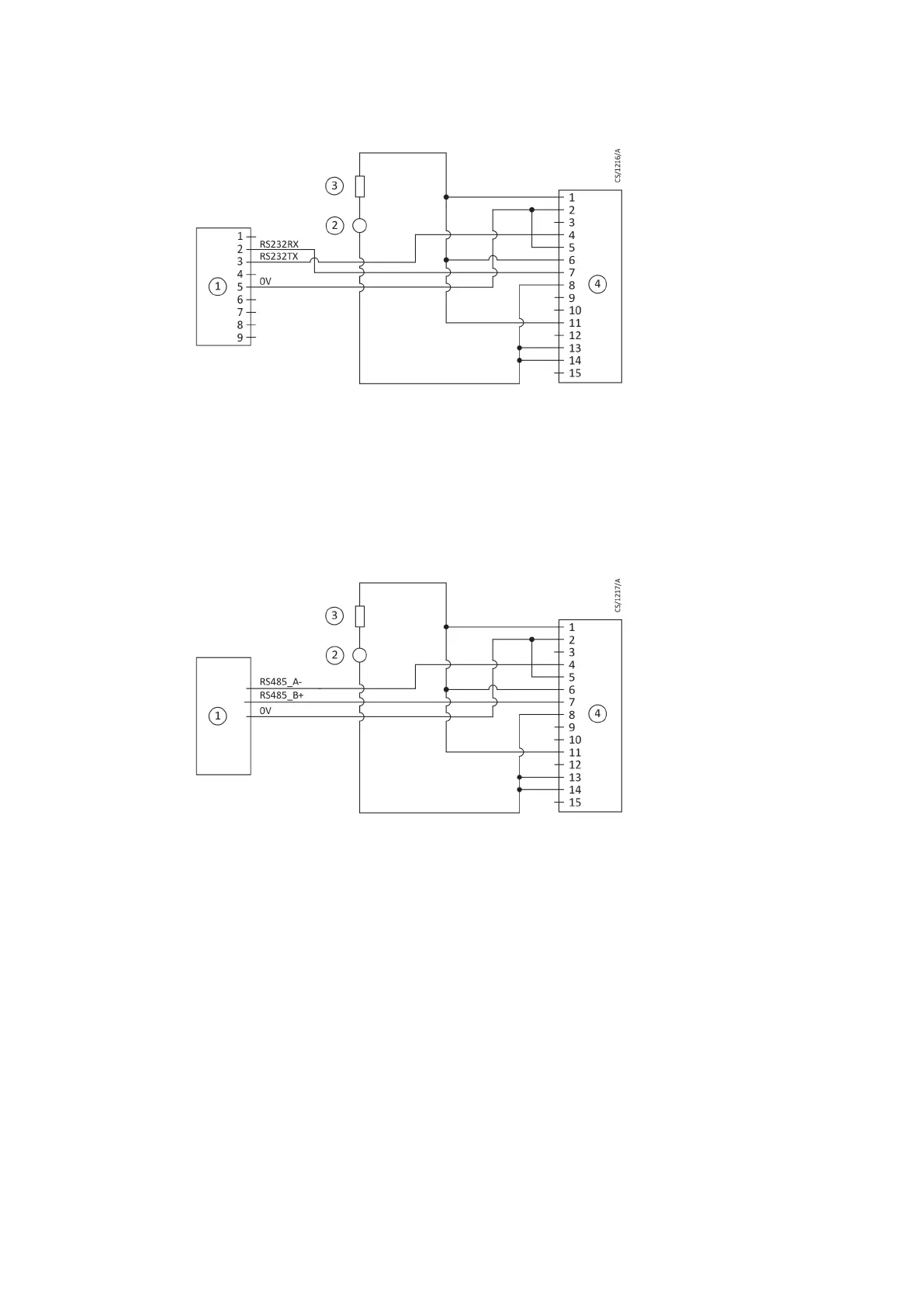

Figure 23 Logic interface connecons - R

S232 serial control

1. RS232 interface on control equipment 2. Oponal 24 V d.c. electrical supply

3. F

use 4. nEXT pump logic interface

1. RS232 interface on control equipment 2. Oponal 24 V d.c. electrical supply

3. Fuse 4. nEXT pump logic interface

Electrical supply connecon to pins 1, 6 and 11 is not required for the nEXT pump as it

has a dedicated pump power supply cable. The fuse is only required if a 48 V d.c.

electrical supply is connected to the logic interface cable.

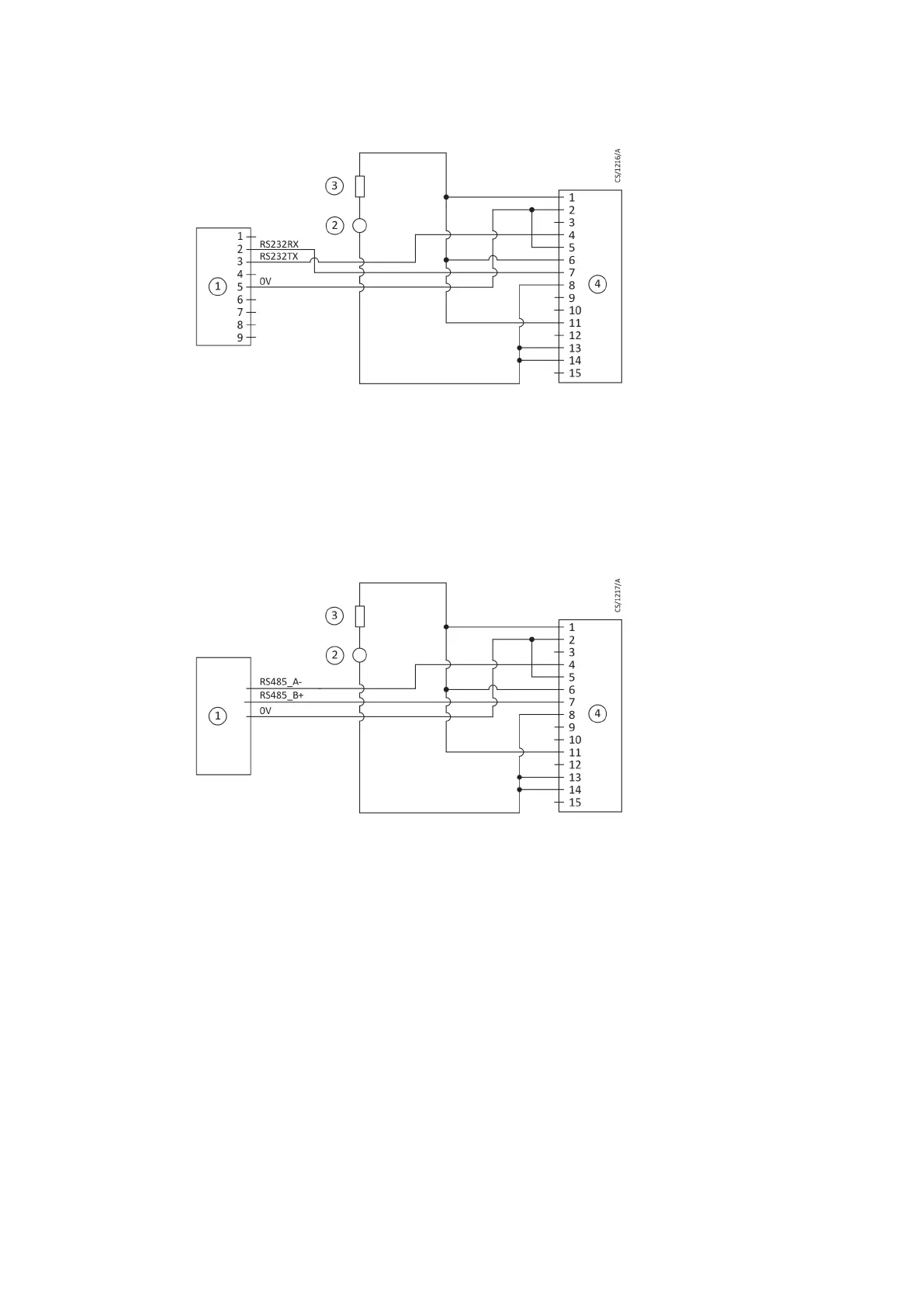

Figure 24 Logic interface connecons - RS485 serial control

1. RS485 interface on control equipment 2. Oponal 24 V d.c. electrical supply

3. F

use 4. nEXT pump logic interface

1. RS485 interface on control equipment 2. Oponal 24 V d.c. electrical supply

3. Fuse 4. nEXT pump logic interface

5.6.2 Serial enable

To send a serial messag

e over the serial link, serial enable must rst be acvated.

Link the serial enable input signal (pin 5) to pin 2 of the customer logic interface mang

half.

Edwards recommends incorporang this link into the serial communicaons cable so

that the serial enable is only acvated when the serial cable is connected. When the

cable is removed, serial enable will become inacve.

Serial enable acts as an interlock for start commands sent over the serial interface. If the

pump is running in serial control mode (having been sent a serial start command) and

the serial enable subsequently becomes inacve, the pump will trigger a fail condion

and will decelerate to rest. To clear this fail condion, re-acvate the serial enable and

send a serial stop command.

08/2021 - ©Edwards Limited

Page 61B8J200880_D

300812671_002_C3

B8J200880_D - Inst

allaon

Loading...

Loading...