If the nEXT pump is being controlled with an Edwards TIC Turbo and Instrument

Contr

oller or TIC Turbo Controller, the TAV solenoid valve can be driven from the TIC.

Refer to the TIC Instrucon Manuals for more informaon.

7.2.4 Alternave valve connected to the vacuum system

When using another vent valve, ensure that a suitable vent restrictor is ed to the

vacuum system to limit the rate of pressure rise.

Refer to Table: Vent restrictor orice diameter if venng the vacuum system chamber for

informaon about vent restrictor sizes. If a suitable vent restrictor is not ed, open the

vent valve only aer the speed of the pump has fallen to 50% of full rotaonal speed.

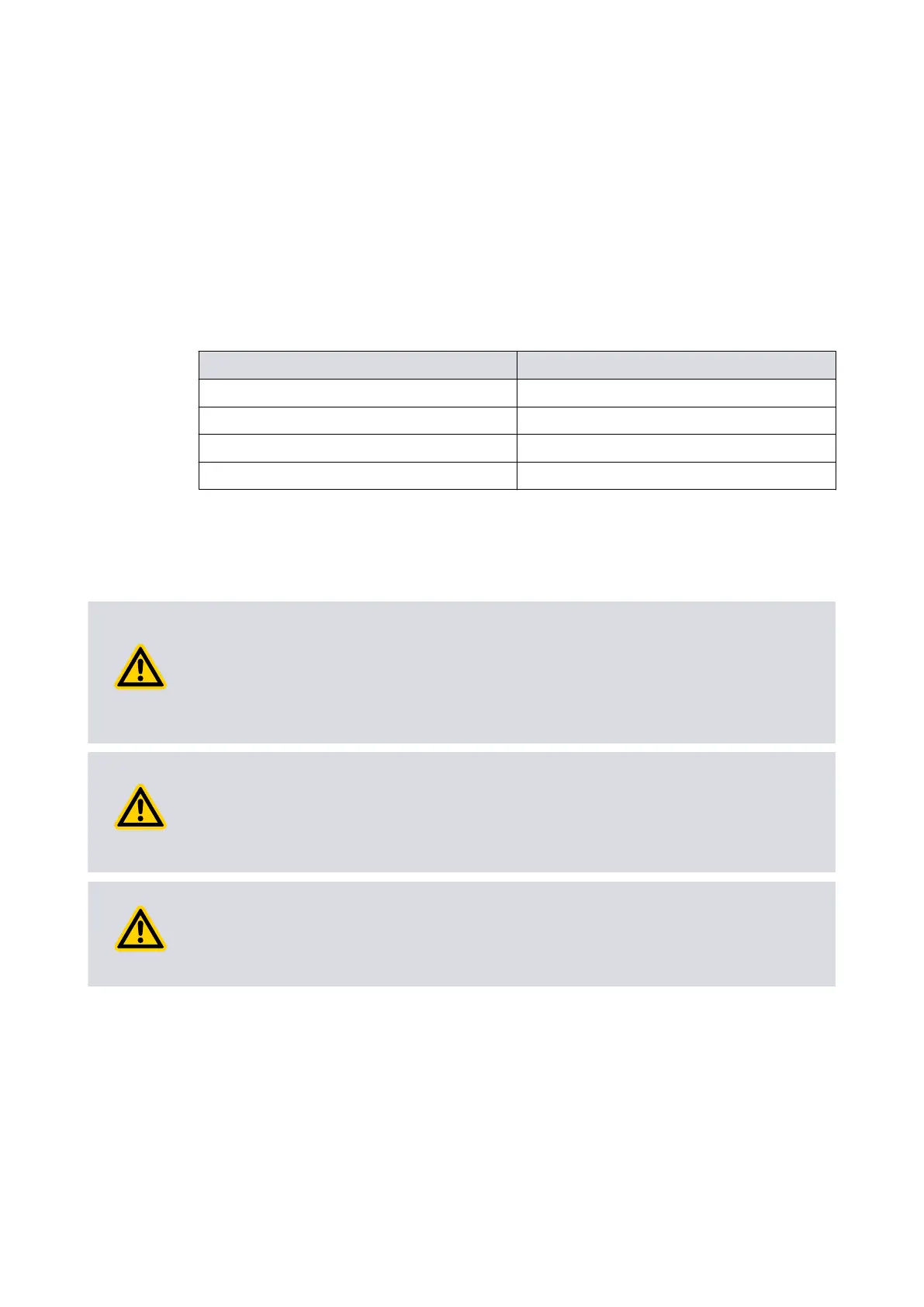

Vacuum system volume (litres) Orice diameter (mm)

< 20 < 1.0

< 10 < 0.7

< 5 < 0.5

< 2 < 0.35

7.3 Operaon with parallel control and monitoring

7.3.1 Start the pump with parallel control

CAUTION:

Do not opera

te the pump with its rotor exposed. Before operang the pump it must

rst be connected to the vacuum system. If the pump is operated with its rotor

exposed, the pump rotor can cause injury as it rotates at very high speeds and the

rotang blades might not be visible.

WARNING:

Do not move the pump whilst it is running. The gyroscopic forces generated by this

movement can cause excessive use of the back-up bearing and may result in

catastrophic failure of the pump.

CAUTION:

When pow

er is restored following a power cut, the pump will restart automacally.

The pump must remain connected to the vacuum system to prevent risk of injury.

In parallel control the pump will accelerate to full operang speed when started.

Start the nEXT pump by linking the start/stop control input to the 0 V control reference

on the logic interface connector.

The green indicator on the motor controller will illuminate when the pump reaches

normal speed. This is 80% of full rotaonal speed by default but a dierent value may

have been selected to suit the applicaon.

08/2021 - ©Edwards Limited

Page 79B8J200880_D

300812671_002_C3

B8J200880_D - Oper

aon

Loading...

Loading...