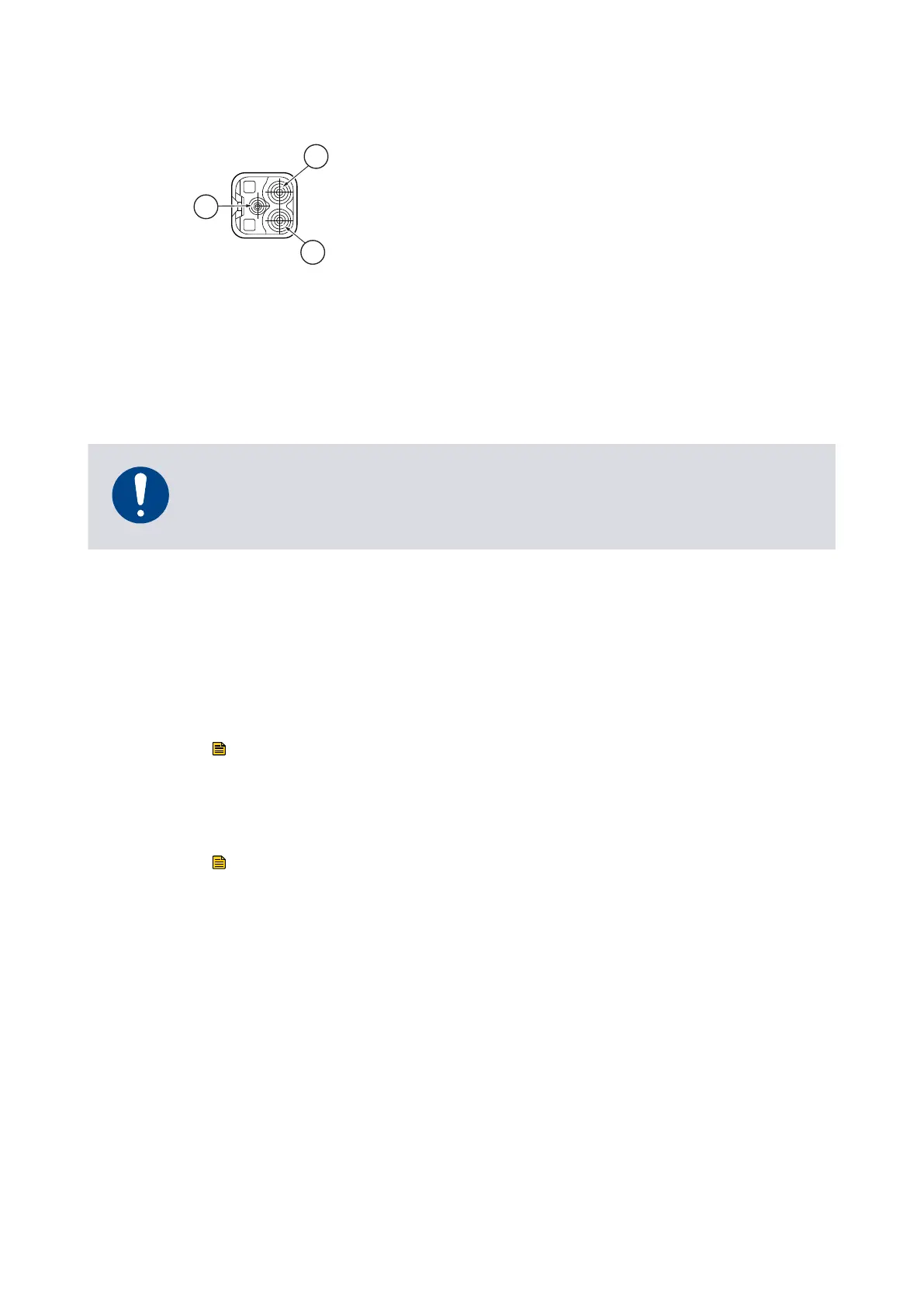

Figure 20 Power supply connector

1. +48V DC Supply 2. 0V Supply

3. Chassis

1. +48V DC Supply 2. 0V Supply

3. Chassis

5.5 Connect the parallel control and monitoring

Connecons for par

allel control and monitoring must be made using a suitable mang

half that is not supplied.

NOTICE:

If using the normal and fail lines t

o drive the coils of d.c. relays, include a back EMF

suppression diode in parallel with each relay coil to protect the pump.

1. Connect the customer control equipment to the control input pins of the customer

logic interface mang half. Refer to Table: Logic interface connector pins, which

idenes the logic interface connector pins.

The control inputs are Start and Standby speed. To acvate either of these control

inputs, connect the control input pin to the 0 V control reference. To start the

pump, connect pin 3 (Start / Stop) to pin 2 (0 V Reference). To stop the pump,

break the connecon between pin 3 and pin 2. To put the pump into standby,

connect both pin 4 (Standby) and pin 3 (Start / Stop) to pin 2 (0 V reference).

Note:

Serial enable is also a con

trol input but is not required in a system operang purely

under parallel control. Make sure that there is no connecon to serial enable (pin

5).

Note:

The RS485/CAN/R

S232 slide switch must be in the (default) RS232 posion to use

the standby or fail parallel interface signals, refer to Connect the serial interface to

the customer control equipment on page 60.

2. To monitor analogue output, connect the customer control equipment to the

pump analogue output (pin 9) and to pin 2 of the cus

tomer logic interface mang

half.

When the pump is shipped, the analogue output is congured to monitor pump

rotaonal speed. To monitor other parameters, re-congure the nEXT pump using

commands over the Serial Interface. Refer to Connecon for serial control and

monitoring on page 59 for further details.

3. To monitor the normal status output, connect the customer control equipment to

the normal st

atus output (pin 15) and to pin 2 of the customer logic interface

mang half.

08/2021 - ©Edwards Limited

Page 58B8J200880_D

300812671_002_C3

B8J200880_D - Inst

allaon

Loading...

Loading...