be achieved if the power supply delivers higher current, up to a maximum in accordance

with Table: Logic in

terface technical data.

If the facility to adjust the power limit seng is not available, use a power supply

capable of delivering enough current to meet the Edwards factory default power limit

seng, shown in Table: Logic interface technical data.

4.9 Logic interface connector

nEXT pumps have a 15-way logic interface connector on the end of the logic interface

cable. Use a suitable connector mang half (not supplied) to connect the nEXT pump to

the customer equipment. Refer to the following table for the connector mang half

type.

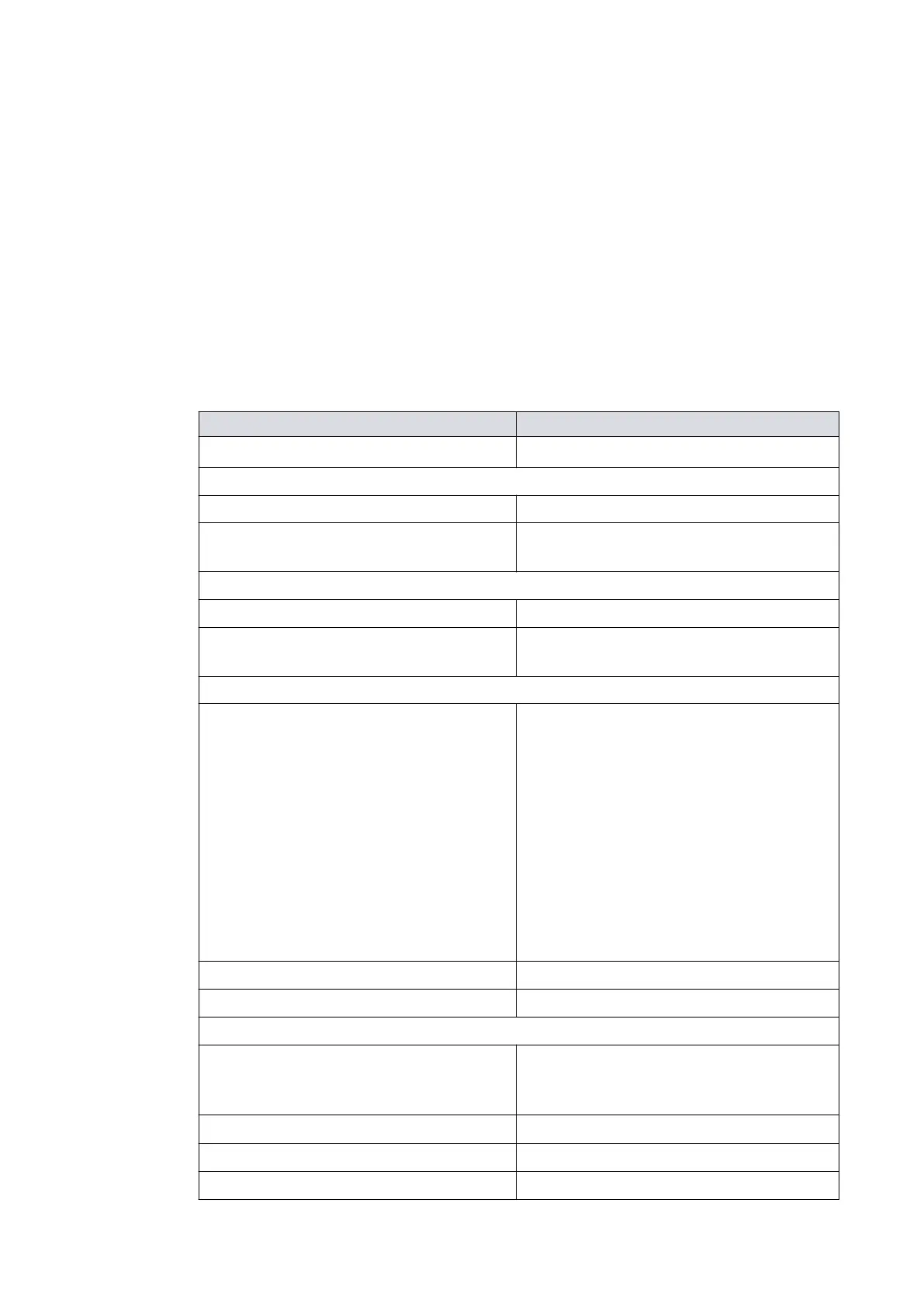

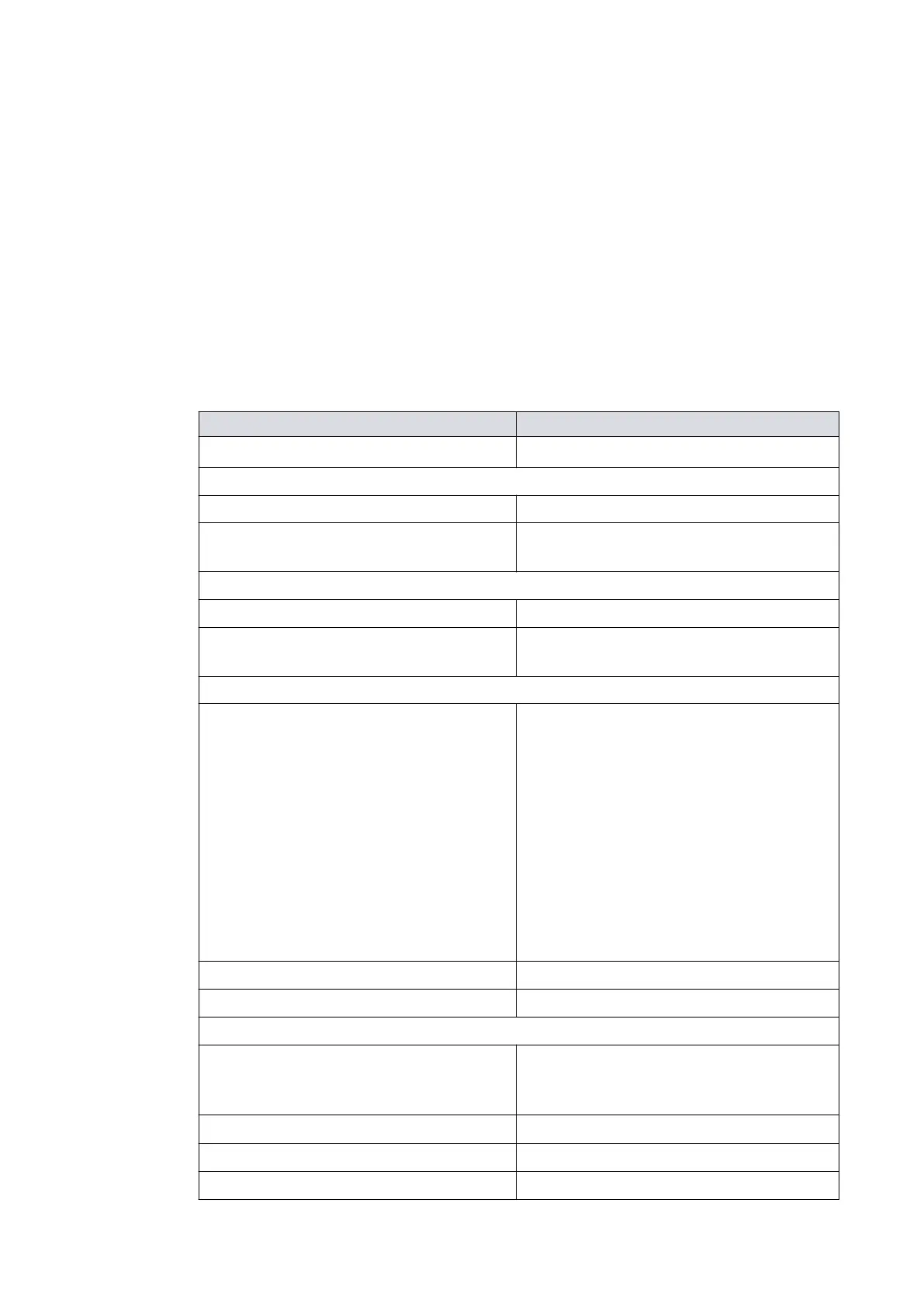

Table 10

Logic interface technical data

Logic interface item

Connector

*

15‑way D‑type male

Start and serial enable control inputs:

Enabled control voltage: low (close) 0 to 0.8 V d.c. (Iout = 0.55 mA nominal)

Disabled control voltage: high (open) 4 to 26.4 V d.c. (internal pull up to 6.4 V

nominal)

Standby control input:

Enabled control voltage: low (close) 0 to 0.8 V d.c. (Iout = 0.29 mA nominal)

Disabled control voltage: high (open) 4 to 26.4 V d.c. (internal pull up to 3.2 V

nominal)

Analogue output:

Output voltage 0 to 10 V d.c. (directly proporonal t

o

measured parameter)

Motor speed: 0 ‑ 820 Hz (0‑100%) for

nEXT730/930D,

0 ‑ 700 Hz (0‑100%) for nEXT1230H

Motor power: 0 ‑ 500 W for

nEXT730/930D,

0 ‑ 660 W for nEXT1230H

Motor temperature: 0 ‑ 100 °C

Controller temperature: 0 ‑ 100 °C

Bearing temperature: 0 ‑ 100 °C

Voltage accuracy ± 0.2 V

Output current

£ 5 mA for specied accur

acy

Normal status output:

Type Open collector transistor plus pull up resis-

tor. Refer to Figure: Interface circuits for

nEXT turbo pump controllers

< Normal speed (default 80%)

O (2.2 kW pull up to 12 V d.c.)

³

Normal speed

On (< 0.8 V d.c. sinking 20 mA)

Current rang 20 mA t

o 0 V

08/2021 - ©Edwards Limited

Page 35B8J200880_D

300812671_002_C3

B8J200880_D - Technical data

Loading...

Loading...