vacuum system volumes in order that the rate of pressure rise remains within the limits

shown in V

ent gas specicaon and vent control data on page 30.

Note:

If a vent res

trictor is used, the me required to vent the vacuum system may be

unacceptably long. The me may be reduced by using a vent valve without a vent

restrictor and waing unl the pump speed has fallen to 50% of full rotaonal speed

before opening the vent valve.

7.2.3 Vent valve control

The TAV solenoid valve can be controlled by the nEXT motor controller or by an Edwards

TIC Turbo Instrument Controller.

The nEXT controller can control the rate of venng, using the vent valve opons in Table:

Vent valve opons. Using this feature the pump can be vented from full rotaonal speed

in a controlled manner that will not damage the pump bearings. Once the pump

rotaonal speed has dropped to below 50% of maximum speed it is safe to hard vent

(open the vent valve fully) provided the backing pump is le on and the backing valve is

open.

To use the nEXT controller funcon, the nEXT turbo pump controller has a 4-pin auxiliary

connector socket on the side of the pump, as circled in , which the vent valve with the

auxiliary connector ed is plugged into.

The controller is capable of controlling a number of dierent venng opons. These are

dened in Table: Vent valve opons.

The controller is capable of accommodang both normally open and normally closed

vent valve types. These are dened in Table: Valve types. A power cycle is required aer

making a change to the valve type, before the auxiliary output circuitry adjusts to

accommodate the requested change.

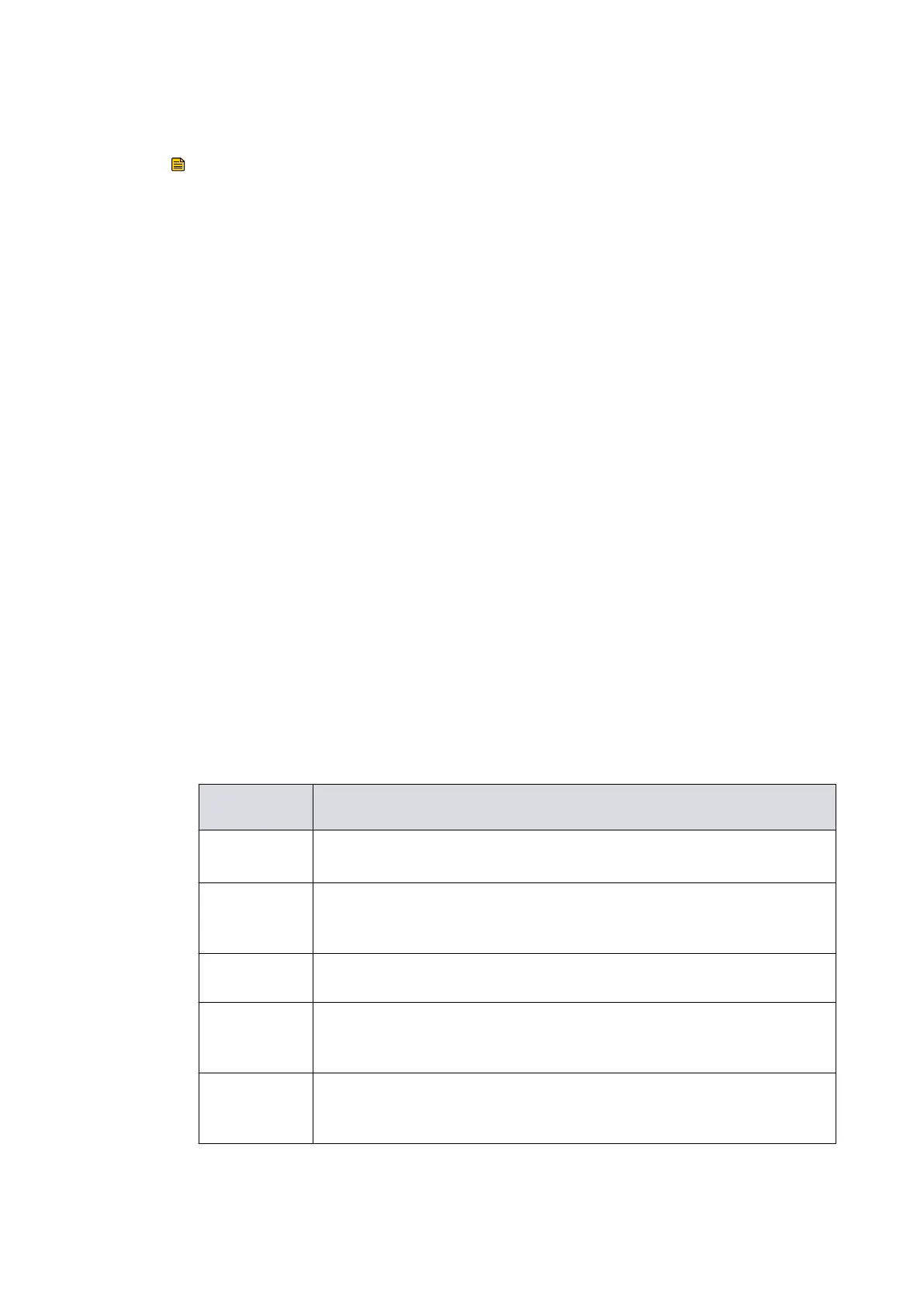

Table 19

Vent valve opons

Opon num-

ber

Descripon of ven

t funcon

0 Vent valve opens fully below 50% full rotaonal speed for either a stop

command or fail condion.

*

1 Controlled venng fr

om 100% to 50% full rotaonal speed and then

vent valve opens fully below 50% for either a stop command or fail

condion.

2 If a stop command is received, vent valve fully opens immediately. In a

fail condion, vent valve opens fully below 50% full rotaonal speed.

3 If a stop command is received, vent valve fully opens immediately. In a

fail condion, controlled venng from 100% to 50% full rotaonal

speed and then vent valve opens fully below 50%.

4 In a fail condion, vent valve fully opens immediately. If a stop com-

mand is received, vent valve opens fully below 50% full rotaonal

speed.

08/2021 - ©Edwards Limited

Page 77B8J200880_D

300812671_002_C3

B8J200880_D - Operaon

Loading...

Loading...