C4 Maintenance 16. Calibration

166 C Series Maintenance Manual Rev.2

After resetting the error, the motor encoder of the joint whose parts have been replaced

will be initialized.

Set the jog mode to “Joint” in [Jog & Teach] and operate the Manipulator in jog motion

to match the home position marks (0 pulse position) of the joint accurately.

When the joint cannot move to the home position, operate the Manipulator to match the

tram mark placed in

Setup & Operation 3.7 Checking the Basic Orientation

Initialize the encoder when the joint matches the home position or the tram mark.

For the encoder initialization, refer to the procedure indicated above.

When the origin of the Joint #5 is calibrated, the Joint #6 will be out of position.

(Due

to the structure of the Manipulator, any offset in the position of the Joint #5 affects the

Joint #6.)

Calibrate the origin of the Joint #6 together when calibrating

the Joint #5.

.

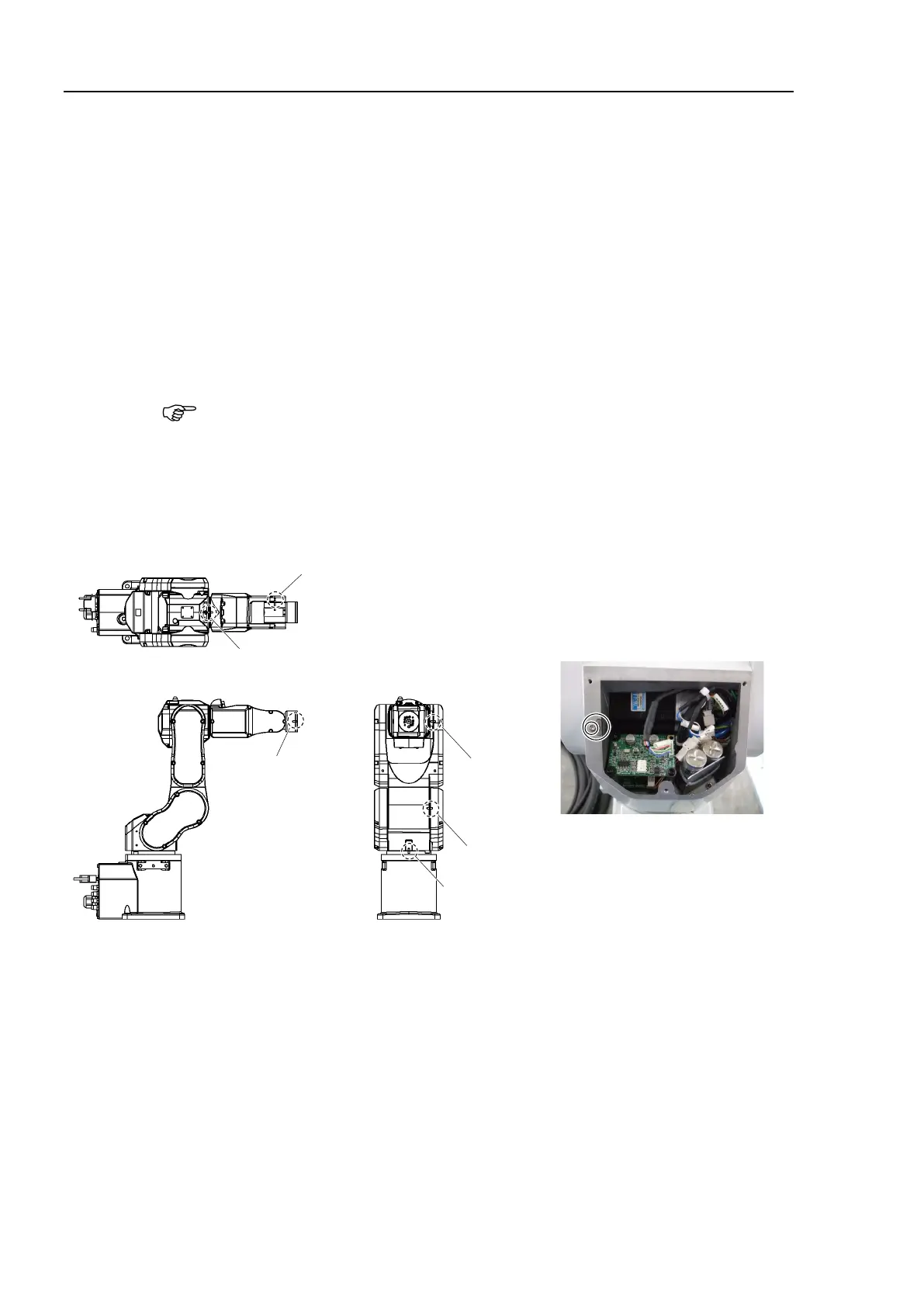

Position of grooves for calibration

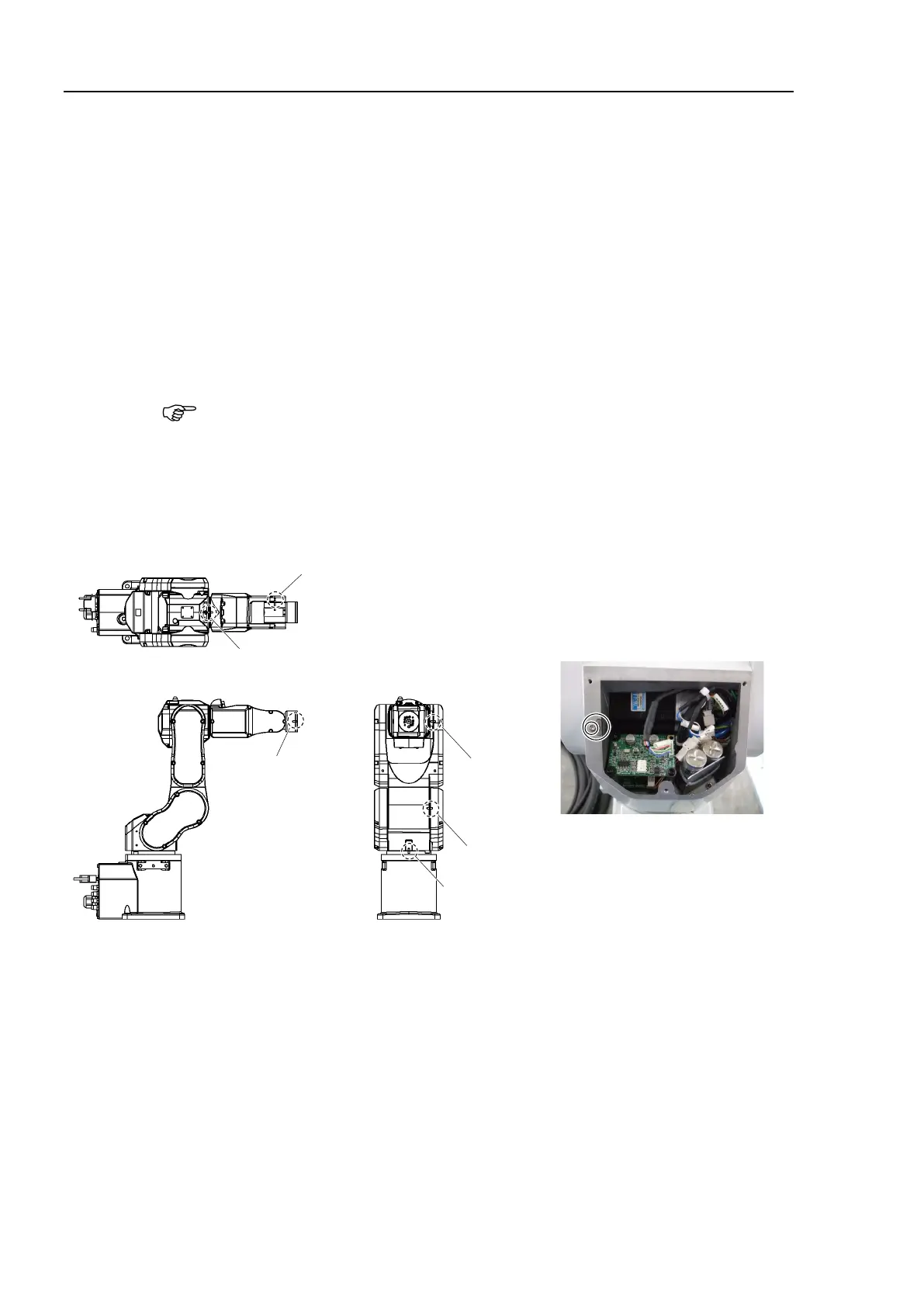

The key is secured to the inside of the

Arm #1 center cover using M4 screw.

Hexagon socket head cap bolts:

M3×6

Be sure to put the key back to the

original position after use.

Position of the calibration key

-1 Prepare the calibration key.

A calibration key is secured inside the Arm #1 center cover using the M4 screw.

careful not to lose the screw.

Loading...

Loading...