C8 Maintenance 7. Joint #3

C Series Maintenance Manual Rev.2 335

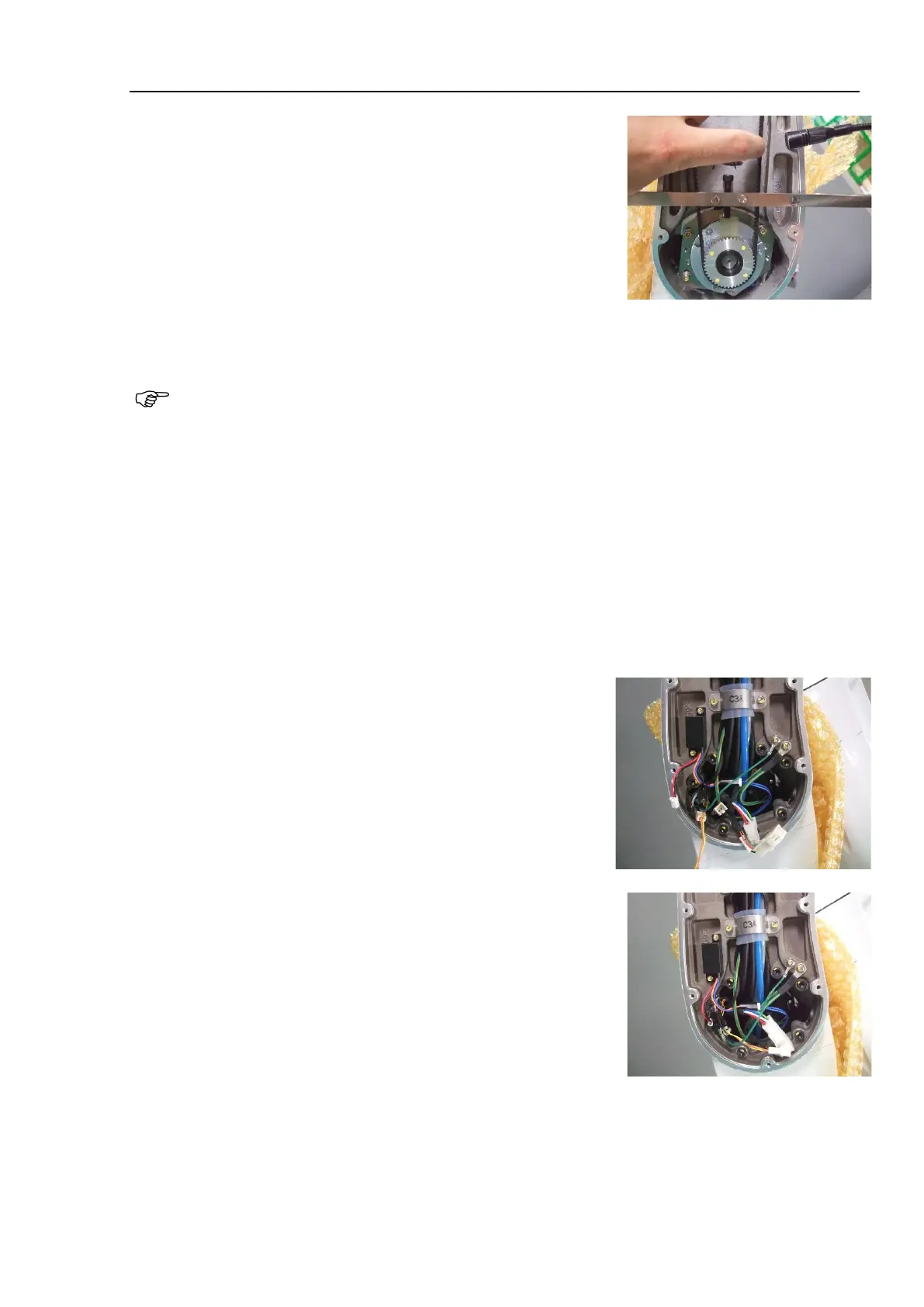

6. Apply tension to the Joint #3 timing belt and fix the Joint #3

motor unit.

Joint #3 timing belt tension: 25 to 85 N

Belt tension meter setting value

Weight: 2.5 g/mm width × m span, Width: 10 mm,

Span: 168 mm

Hexagon socket set screw: 3-M4×20 (with a plain washer)

Tightening torque: 4.0 ± 0.2 N·m

Regarding belt tension:

- Jumping (position gap) may occur if the value is below the lower limit

-

Vibration (abnormal noise) or reduction of life of the parts may occur if the value exceeds the upper

limit.

- W

hen you replace with a new belt, belt extends and the belt tension may decrease in the initial stage.

Make sure to operate the robot two to three days and check the belt tension again.

When using the belt tension tensile jig (maintenance part):

Fix the belt tension tensile jig (for J1, J2, J3) with the screws (2-M4×35) and push the rubber against the

pulley.

Tension is applied by pushing the set screw (M6×25) with the rubber.

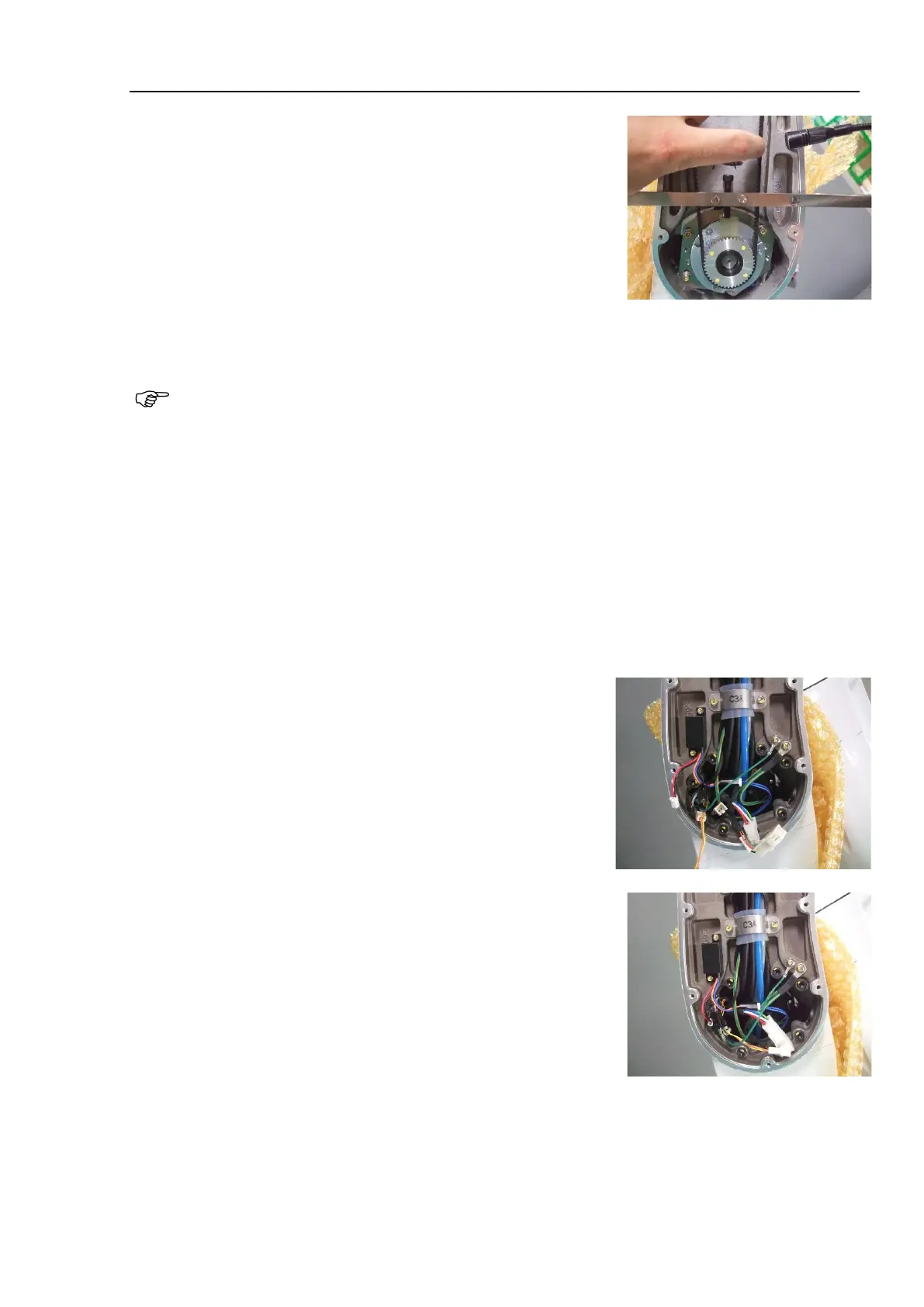

7. Install the brake power supply.

Cross recessed head screw with captive washer: 2-M3×6

Tightening torque: 0.45 ± 0.1 N·m

8. Connect the following connectors.

Connectors: X131, X031, BT3, BR031

9. Install the Arm #2 side cover.

For details, refer to C8 Maintenance: 3. Covers.

10. Perform the calibration.

For details, refer to C8 Maintenance: 16. Calibration.

Loading...

Loading...