Rev. A Mechanism Configuration and Operating Principles 2-13

TM-U950/U950P Technical Manual

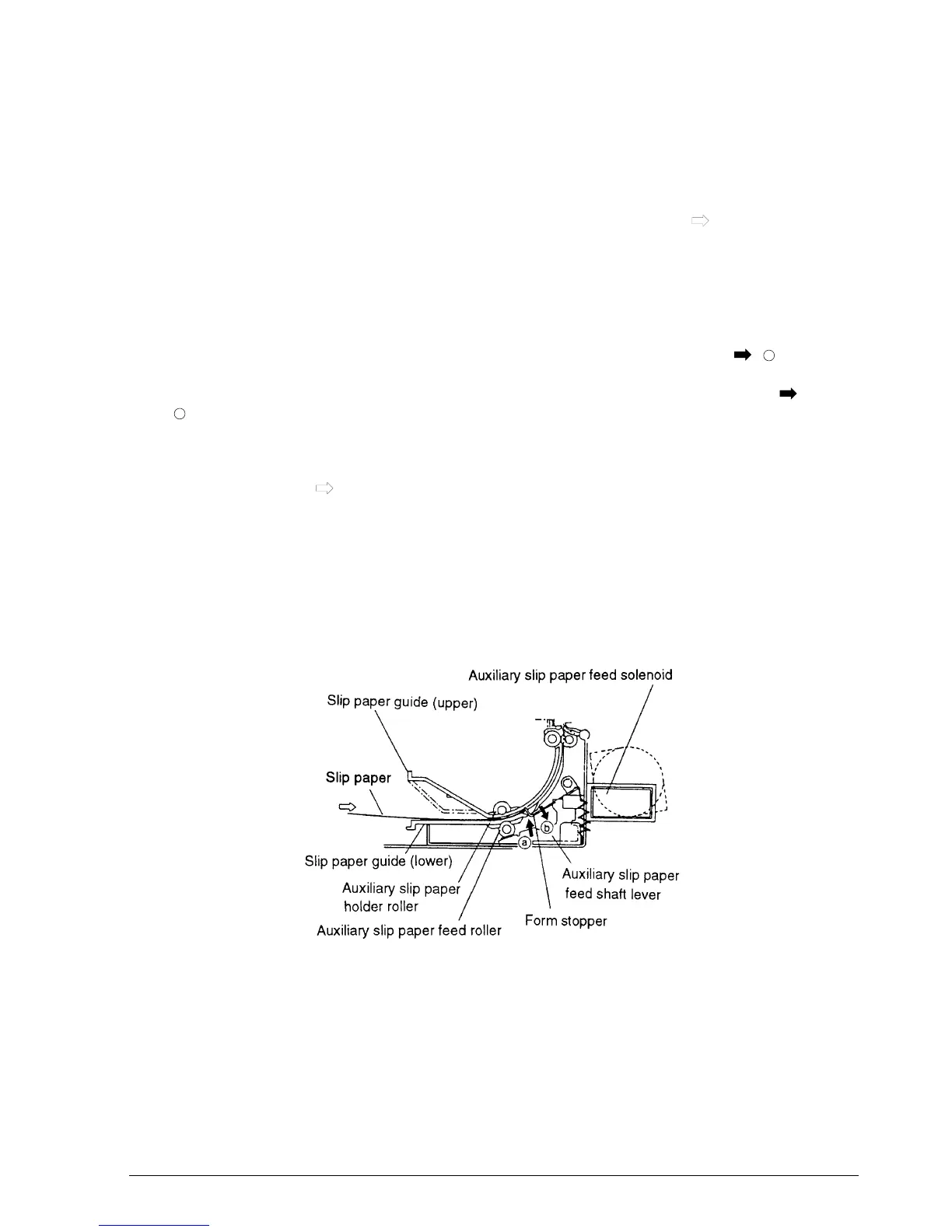

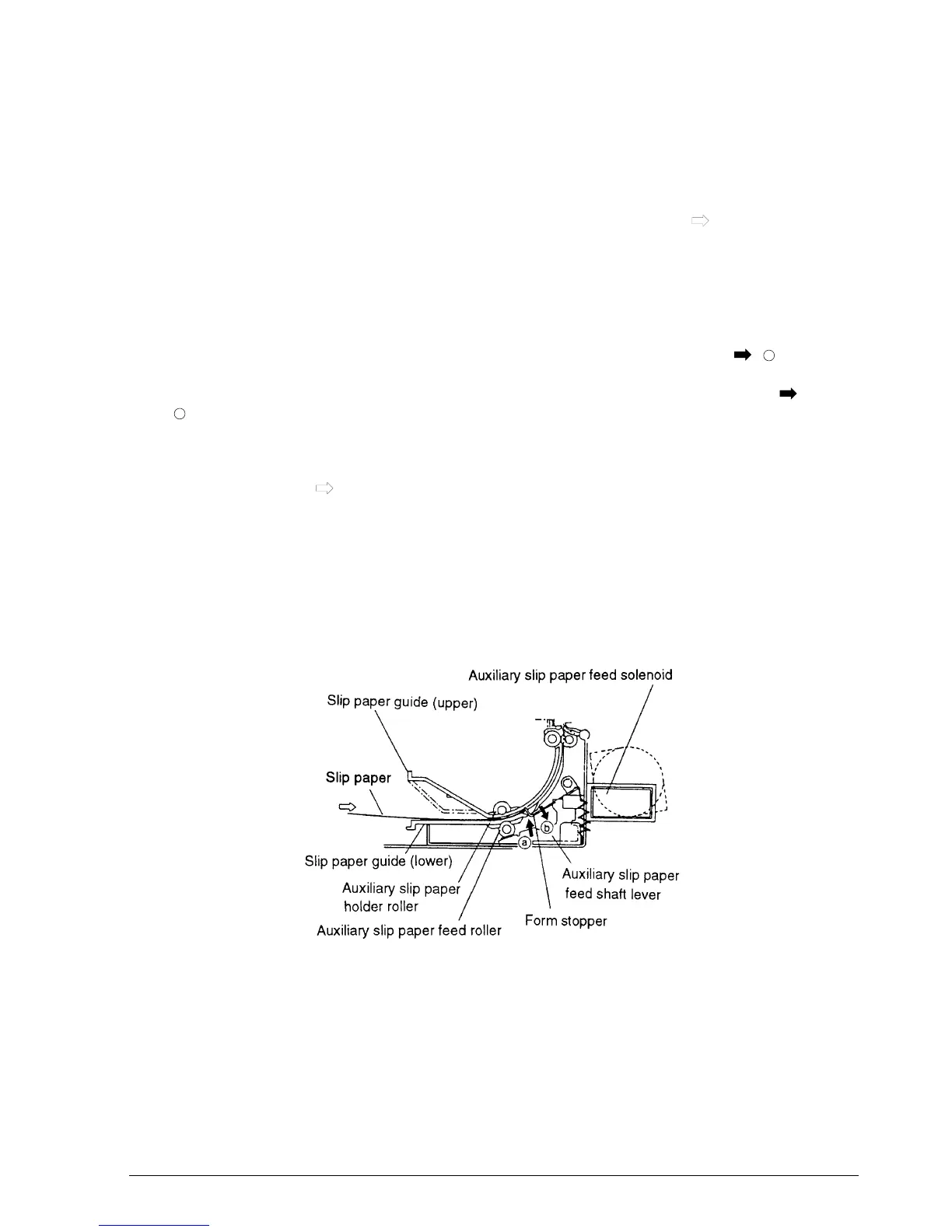

Slip paper positioning operation

A form stopper placed at a right angle in the slip paper path blocks the path due to the action of

the form stopper spring (Figure 2-21).

When the slip paper is inserted along the slip paper guide (lower) in the direction, the paper

can enter as far as the stopper (Figure 2-21).

Next, the J/S switching solenoid is powered while rotating the journal paper feed motor several

steps in the forward and backward directions. The J/S change lever now causes the J/S

switching gear, which has been positioned to feed the journal paper up to this point, to move to

a position to feed the slip paper. The auxiliary slip paper feed solenoid is then powered, causing

the auxiliary slip paper feed shaft lever linked to the ferrite core to move in the direction.

The roller of the auxiliary slip paper feed roller is pushed up against the auxiliary slip paper

holder roller. The auxiliary slip paper feed shaft lever moves the form stopper in the

direction, thus opening the slip paper path and completing the preparations for slip paper

feeding (Figure 2-21).

The journal paper feed motor now rotates a certain number of steps (depending on the slip

paper format) in the direction, causing the J/S switching gear, paper feed reduction gear, slip

paper holder roller, slip paper feed belt, auxiliary slip paper holder roller, and auxiliary slip

paper feed roller to move in turn and thus bring the slip paper into the printing position (Figure

2-23).

Immediately before the operating sequence described above, the head carriage is moved to the

right most position. When positioning is completed, the auxiliary slip paper feed solenoid is

turned off, and the J/S switching solenoid is set to hold (during slip paper printing and paper

feeding).

a

b

Figure 2-21. Slip Paper Positioning (1)

CONFIDENTIAL

Loading...

Loading...