Operating of the Machine

Paraquda Startup & Safety © Essemtec AG

4-41

0000003/11 / November 4, 2014

Possible cause: Inadequate nozzle (nozzle contact area too big or too small)

Verify recipe, probably wrong nozzle chosen for

the appropriate component.

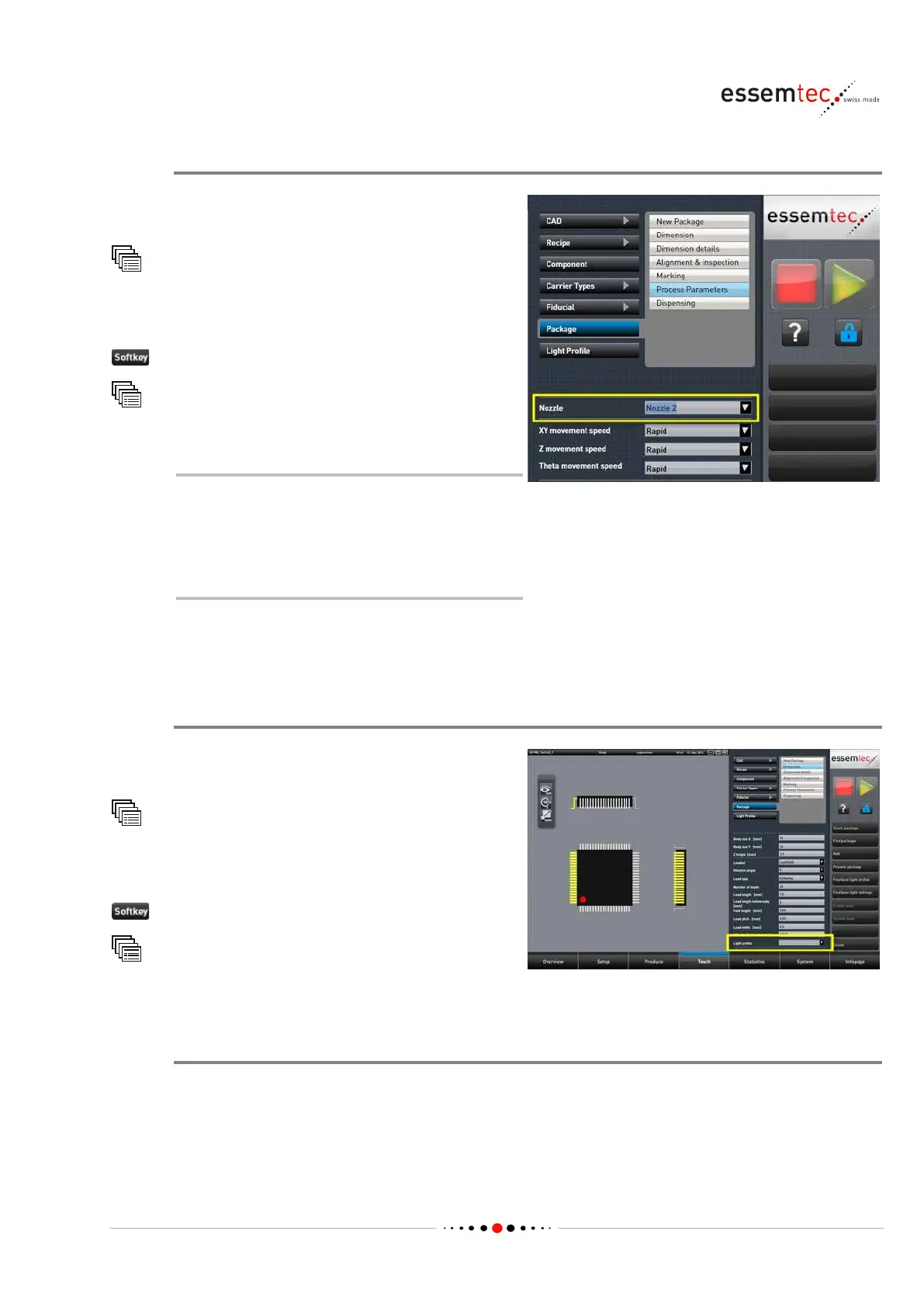

Package

Out of the package list, select the appropriate

package.

Package

Process Parameters

Before changing the nozzle type make

sure the components are correct

presented by the feeder (no tombstone

or drawbridging effect in carrier pocket

or cavity).

4.4.9 Component vision inspection failed

Possible cause: Insufficient illumination

Verify the light profile, probably wrong profile

chosen for the appropriate component.

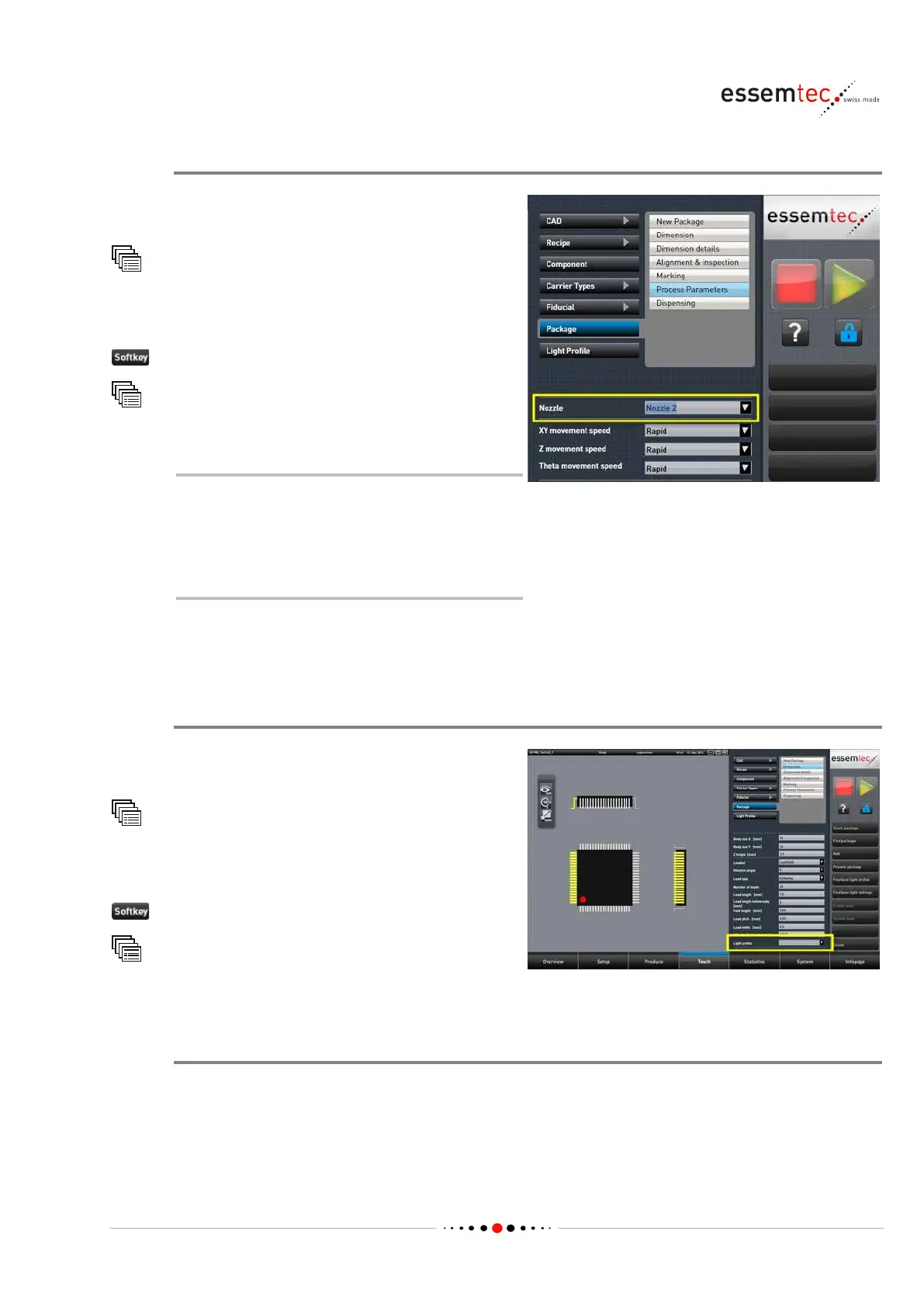

Package

Out of the package list, select the appropriate

package.

Package

Possible cause: Geometrical parameters not valid

Compare the geometrical specs of the appropriate component with the values in the recipe.

Loading...

Loading...