Equipment Overview

2-8 © Essemtec AG Paraquda Startup & Safety

0000003/11 / November 4, 2014

An ascending T value means a rotation counterclockwise, seen from top to bottom of the machine.

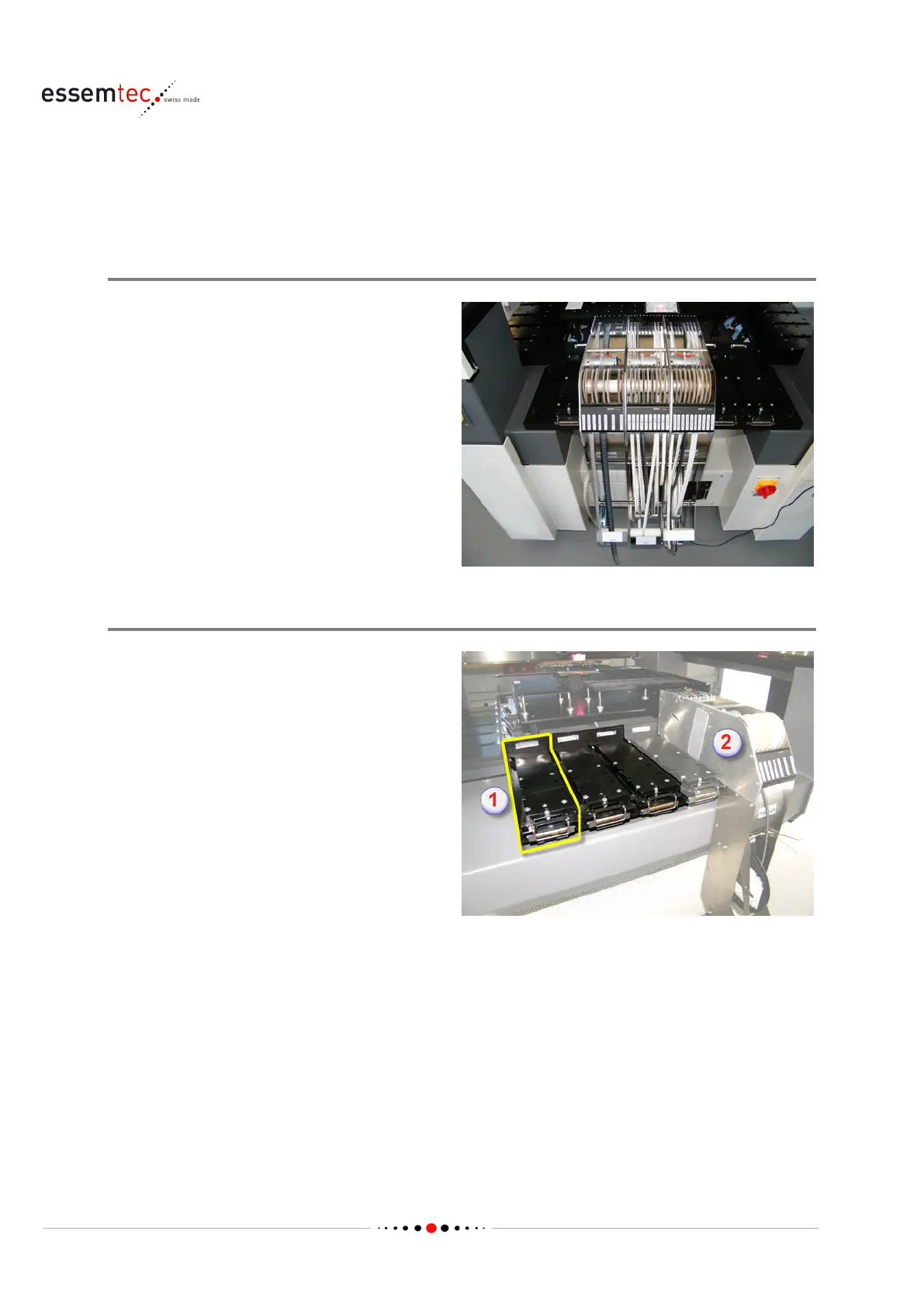

2.3.6 Rack / Feeder

Overview

For picking up, surface mount components can

be placed along all side

s of the machine. Most

components are supplied on paper or plastic

tape or in sticks, the tape reels and sticks are

kitted onto feeders connected to the machine

rack.

Feederrack / Slots

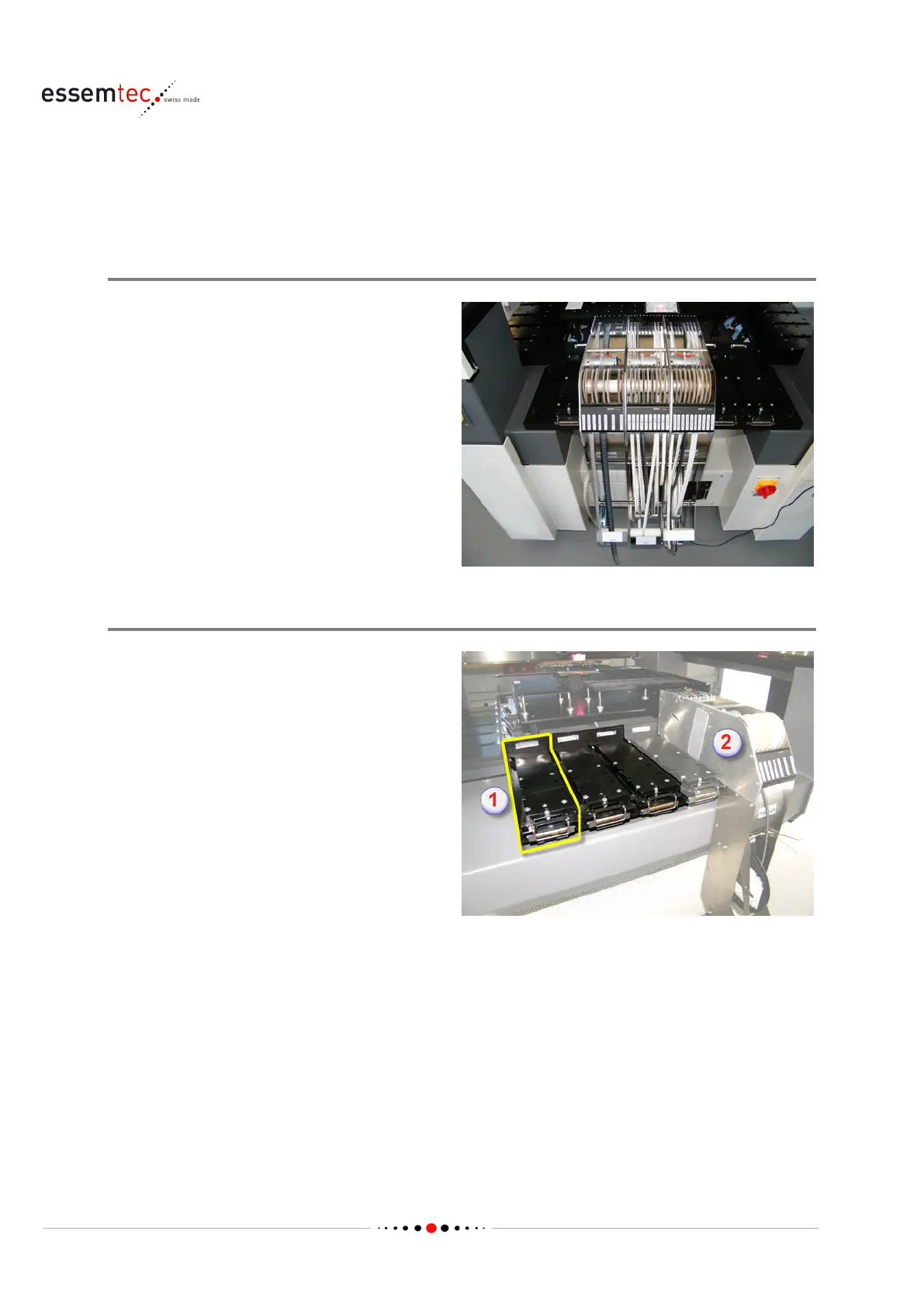

All feeder cassettes with intelligent interface

require a Feederrack. The rack is mounted on the

machine base and connected to the PC (on

picture: rack for CLM feeders).

A feeder rack consists of Slots (1). Each slot can

carry a feeder cassette (

2) with one or more

feeder lanes (depending on rack

- and feeder

After disconnecting a feeder cassette for

refilling, the pickup positions must never be re

-

taught because the rack precisely repositions

the feeder.

Feederracks can be mounted on all

four sides of

the machine. Each side has rack space for 60

feeder lanes. This gives a maximum of 240

feeder lanes with 8 mm width.

Loading...

Loading...