Operating of the Machine

4-8 © Essemtec AG Paraquda Startup & Safety

0000003/11 / November 4, 2014

After the mentioned check has been done and the air pressure is available again, the production

can be continued. Press

(START) to start the machine. The machine continues with the next

cycle.

Power Failure

Usually the remaining energy for a very short time is sufficient for a controlled stop of the axes. The

started process cycle cannot be finished. That means process failures can occur.

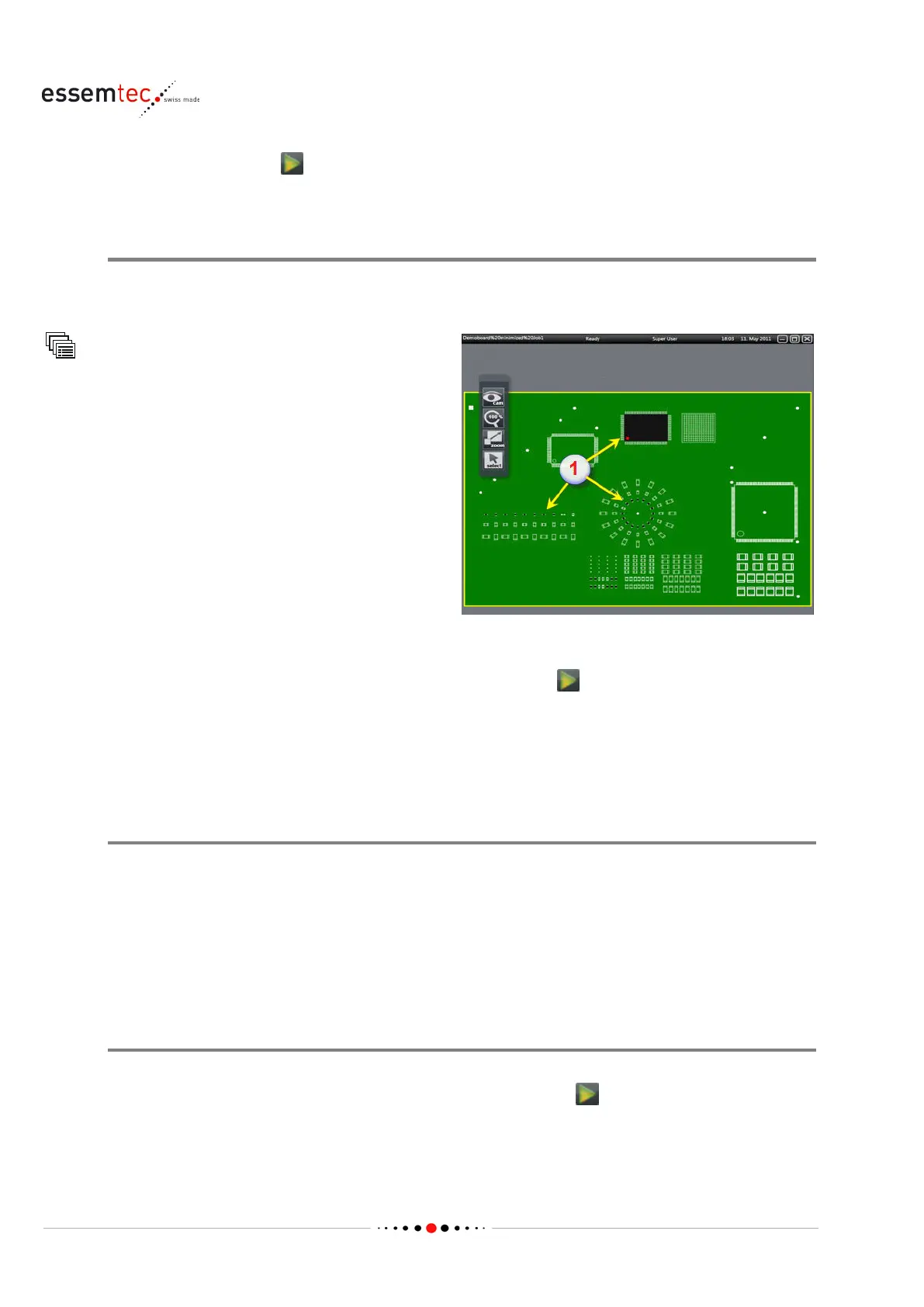

Place Control

The 'logical map' (1) of the machine has to be

compared with the real appearance on the PCB.

In case of any differences between the picture of

the machine and the real appearance on the

board, detailed information how to pr

oceed can

be found in chapter 'Solve Malfunctions / Handle

unordered Stops' on page

4-37

After the mentioned check has been done and the electricity is available again, the production can

be continued. For this purpose start ePlace again and initialize the machine again (described in

chapter 'Power up the Machine' on page 4-1). Afterwards press

(START) to start the machine.

The machine continues with the next cycle.

4.2.4 Unordered Stops

Cause of unordered stop

If during normal production, the machine stops for any reason, the signal lamp lights up (depends

on signal tower configuration) to indicate that the machine has stopped and requires operator

intervention.

This may happen for a number of reasons, e.g. due to a shortage of material or a jammed PCB.

What ever the reason for the stop is, an error message, warning or notification will always be

displayed showing the cause of the stop.

Problem Solving

The action to solve a problem depends on the cause of the stop. If the machine stopped due to a

material shortage, simply replenish the missing material and click

(START button) to continue

production.

If the problem is more serious an error message or warning will be displayed giving detailed

information for troubleshooting.

Loading...

Loading...